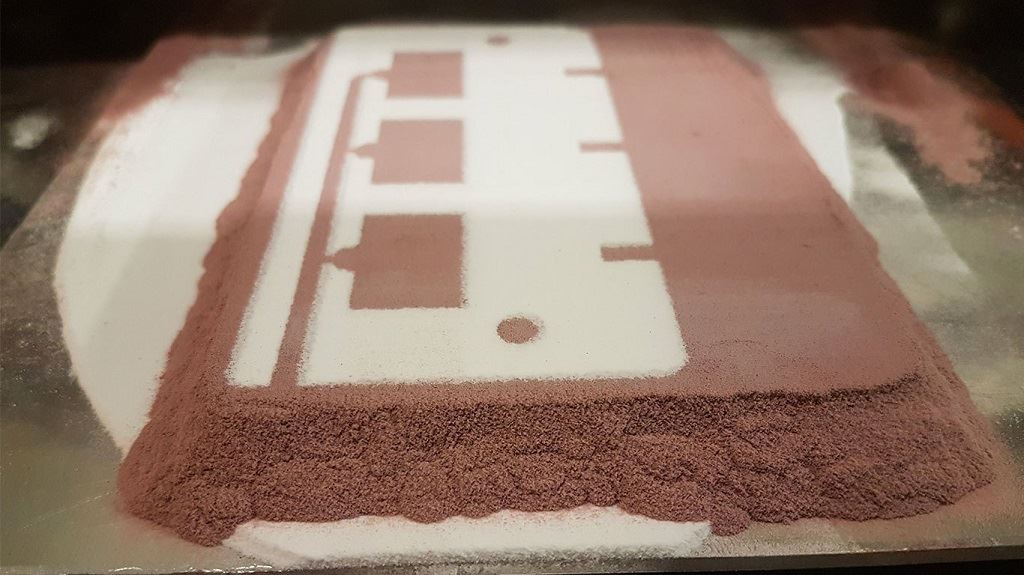

![A polymer 3D print using PA12, with red coloration from mixing with an iron oxide powder. [Image: Aerosint]](https://fabbaloo.com/wp-content/uploads/2020/05/AerosintPolymers_img_5eb09476b7e1e.jpg)

Aerosint’s unique multi-material powder bed 3D printing process is bringing new possibilities not only to additive manufacturing, but to its security as well.

The Belgium-based company developed an intriguing, and still unique, process by which to 3D print with multiple materials, even multiple metals, on a powder bed system. While powder bed 3D printing technologies like SLS and SLM have already opened up new capabilities for how to make parts, the idea of doing so with more than one type of powder is expanding interest in powder bed processes that otherwise faced some limitations.

Digital Manufacturing Security

One of those limitations came in security. As 3D printing industrializes, IP protection is edging ever nearer the spotlight. Counterfeit products present a major concern — and not one that most consumers think about. But securing parts and ensuring they are authentic, and that IP stays only among those with appropriate rights, is an increasingly large focus in the industry today.

Maryland-based InfraTrac is among the companies seeking to secure 3D printing. Using a taggant approach, InfraTrac uses a ‘chemical fingerprinting’ process to infuse security right into the materials that make up a part itself. The company has collaborated with other companies in the 3D printing space already to extend both awareness and protection.

This week, InfraTrac and Aerosint introduced their own collaboration — which for the first time brings chemical security into a laser powder bed fusion (LPBF) 3D printing process.

Multi-Material Powder Bed Security

Until Aerosint’s selective powder deposition coater came onto the scene, LPBF processes were not a candidate for the taggant approach, limited by the use of just one material. Aerosint explains:

“In a first step, Aerosint is producing simple demonstrator parts from polymer and metal that include ‘fingerprinting’ sites based on a powder formulation developed by InfraTrac, which will then test and verify the parts. This collaboration forms the basis for simple, robust, and scalable part authentication for industries in which strict quality control is critical.”

3D printing is playing an ever-larger role in critical industries like aerospace, automotive, and healthcare, where it’s vital — literally vital, as human lives may be impacted — that all parts are top quality and truly validated.

Aerosint’s announcement highlights that in digital manufacturing, the security of the parts made for such industries goes from end to end — concerns don’t stop after a digital file reaches the manufacturer. They say:

“Software protections and digital rights management are necessary to protect the intellectual property in that file. However, none of those digital protections are going to keep us safe from 3D-printed counterfeit parts and products: once the print is complete, its digital safeguards lose their power. Anti-counterfeiting for additive manufacturing needs to be integral to the final printed product.”

Covert Anti-Counterfeiting

There are several approaches to protect the products; we’ve seen QR codes, serial number matrices, and other types of embedded tags examined.

This ‘fingerprinting’ method is a relatively simple covert method that can be scaled up. InfraTrac uses commodity taggants that are highly detectable, ‘hiding’ them in a small spot of a print, which makes it harder to find and duplicate — but almost immediately findable to those who know what they’re looking for and where to find it.

They further explain:

“This compatible-chemical approach gives InfraTrac millions of taggant combinations, with open supply chain options, but it does rely on a multimaterial print process. Until now, powder bed printing was a problem: clearly important for scalable industrial applications, but limited to single materials.”

As so many issues in 3D printing do, this solution comes down to viability via voxel-level control. Aerosint’s ability to selectively and precisely deposit powders is key — along with the fact those powders can be different within a single print — to the success of this approach. The taggants “can be made visually identical to the part’s bulk material,” which again underscores the importance of the covert approach to anti-counterfeiting.

Gaining confidence in parts, especially critical-use parts in highly regulated industries, is a must for 3D printing to continue into more mainstream use. This collaborative effort shows another step toward a more secure, scalable additive manufacturing industry.

Via Aerosint

Create It REAL has signed a deal with Spentys to help devise a secure system that provides onsite 3D printing of orthopedic devices in practice offices.