![Metal 3D prints on top of a spool of BASF’s new Ultrafuse 316L stainless steel filament [Source: BASF]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0938099668.jpg)

BASF announced a new filament based on steel powder: Ultrafuse 316L.

This material falls into the category of advanced 3D printing materials, as it is truly an industrial material suitable for metal prototyping.

Unlike the powder-based metal materials used by many metal 3D printers, this is a filament, and according to BASF, can be used “on any conventional, open-material FFF printer.”

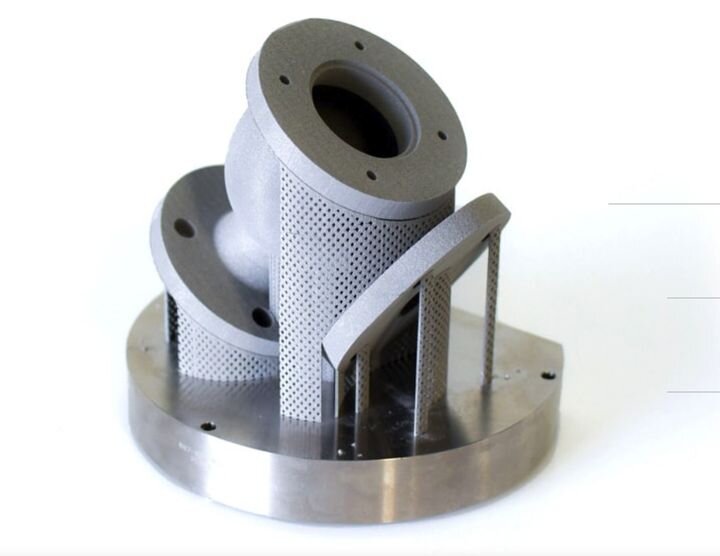

As FFF 3D printers are typically used to print thermoplastics, I must describe what’s going on here. The new Ultrafuse 316L is a composite material, made from a combination of fine 316L steel powder and a polymer binder. The material is produced in either 1.75mm or 2.85mm filaments that can easily be 3D printed on FFF equipment, as the binder softens, allowing the material to flow through the nozzle for deposition.

What you end up with is a “green part” that is part steel powder and part polymer, which is holding it together. There must then be post-processing steps in which the binder is removed and the remaining metal particles are sintered together. Typically this is done in a furnace.

BASF is setting up a network of specialized providers that can transform the green part through debinding into a “brown” part, and then a fully sintered metal final part.

High Ratio Metal 3D Printer Filament

What’s interesting about Ultrafuse 316L is its ratio of metal powder to binder. In other metal filaments we’ve typically seen ratios of 50-80%. However, Ultrafuse 316L has an incredible 90% ratio.

Thus after the sintering process that removes the binder, the resulting pure 316L object will have shrunk in all dimensions. BASF says the shrinkage is approximately 20% in the XY axis and 26% in the Z axis. Therefore those using Ultrafuse 316L will have to slightly enlarge their 3D models appropriately to ensure the resulting part is the correct dimensions.

High-Quality Metal Filament

There’s something else. BASF says:

”The metal content in the high 90 percent range and the even distribution of the metal within the binder matrix reduces the risk of defects and increases the success rate.”

It appears BASF has taken some action to ensure even particle distribution in their production process. This is actually quite important, as it should ensure each particle is surrounded by some amount of binder. That should reduce uneven flows during extrusion, increase surface quality and reliability.

Using Metal Filament

BASF also says:

“Due to immobilization of metal particles in the binder matrix into a filament dramatically reduces the potential hazards of handling fine metal powders when compared to Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), Direct Metal Deposition (DMD), and Binder Jetting.”

This is also quite true, but I don’t think the availability of a filament would necessarily change a company’s strategy on selection of a metal 3D printing process. There are quality differences between the powder and filament processes, as well as a number of production aspects to consider.

One important aspect is that some metal 3D print operations have achieved industry certifications that permit use of the printed metal parts in various industries. These certifications are only in force if the operator continues to produce the parts in exactly the same way: the same materials on the same machine using the same operational process. I’m not sure filament-based metal 3D printing is at that level quite yet.

Metal 3D Print Sintering

![Two spools of BASF’s new Ultrafuse 316L stainless steel filament [Source: BASF]](https://fabbaloo.com/wp-content/uploads/2020/05/Ultrafuse-316L-FFF-metal-3d-printing-filament-spool_img_5eb09381014d3.jpg)

I should also note that if you intend to use this filament, your workshop must include (or have access to) a sintering furnace capable of reaching the necessary temperatures to sinter 316L steel. This is not a process that should be undertaken by casual 3D printer operators.

Printing with Ultrafuse 316L should be relatively straightforward, as it has an extrusion temperature range of only 230-250C, but it does require a relatively high build plate temperature of 90-120C, temperatures that are available on desktop 3D printers that are able to 3D print in ABS. You’ll also need a glass build plate with kapton coating and a hardened steel nozzle to withstand the constant grinding of the fine metal particles.

One more thing: BASF is selling Ultrafuse 316L in 3kg spools. If that sounds heavy as compared to typical thermoplastic spools of 1kg, think again. The density of 316L steel is approximately 8X that of ABS, so a 3kg spool of Ultrafuse 316L filament will visually appear to have about a third the size of filament on a typical 1kg thermoplastic spool.

Ultrafuse 316L Weight

BASF says you’ll get 250m of 1.75mm filament or 100m of 2.85mm filament, both on 3kg spools. That’s approximately 0.6L volume of material. A typical 1kg thermoplastic spool will contain around 1.0L of material. Thus you may be buying more spools of Ultrafuse 316L to complete your prints.

BASF says they will initially sell the product to the public through three partners: Ultimaker, MatterHackers and IGo3D. However, none seem to have the material on sale yet so we do not know the cost per spool.

[UPDATE] IGo3D now has the new material on sale here. Their price is €460 (US$511) per 3kg spool (VAT included).

Via BASF

1 comment

Comments are closed.