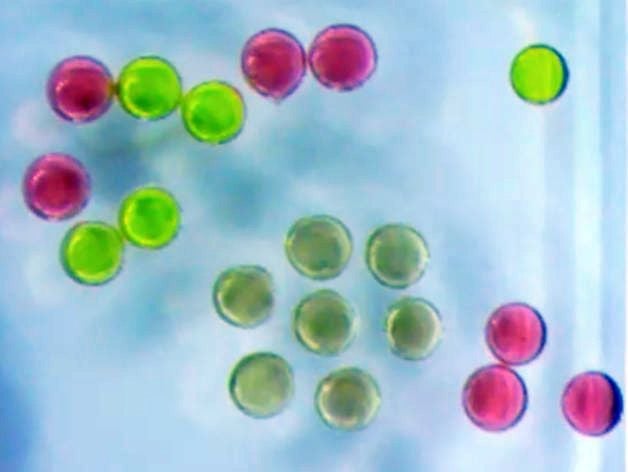

![Magnetic and paramagnetic 3D printed 1mm droplets [Source: Berkeley Lab']](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0939abadbb.jpg)

Researchers at the Berkeley Lab have developed a technique for 3D printing liquid structures that are reconfigurable.

The researchers were experimenting with ferro-fluids, which are liquids infused with ferric nanoparticles. These iron oxide particles are only 20 nanometers across, so they are extremely tiny.

The liquid was 3D printed into 1mm droplets through the use of a modified conventional 3D printer. The droplets were 3D printed into a liquid. So far, this seems pretty routine.

By doing sophisticated analyses, they were able to determine that a phenomenom known as “interfacial jamming” occurred, where the nanoparticles in each droplet rushed to the edge of the droplet, forming a kind of boundary between the two and maintaining droplet internal structure.

The researchers then applied a magnetic field to the 3D printed solution through the use of a nearby electrified coil. As they anticipated, the ferro-particle infused droplets moved towards the magnetic field.

Again, this seems quite normal.

Then, something very unexpected occurred. When the researchers removed the magnetic field, they observed the droplets doing this:

![3D printed magnetic droplets move synchronously [Source: Berkeley Lab]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0939bc2ff9.gif)

Berkeley Lab says:

“Through magnetometry measurements, the scientists found that when they placed a magnetic field by a droplet, all of the nanoparticles’ north-south poles, from the 70 billion iron-oxide nanoparticles floating around in the droplet to the 1 billion nanoparticles on the droplet’s surface, responded in unison, just like a solid magnet.”

Controlling Ferric Nanoparticle Droplets

Somehow the droplets had become magnetic due to the exposure to the magnetic field. Ferric materials becoming magnetic has been long observed in solid materials, but never in a liquid previously.

It seems that the “jammed” nanoparticles on the droplet boundary act in an analogous manner to solid ferric particles. Free-floating nanoparticles might become magnetic, but it would be of no consequence because a free-floating particle would simply rotate as required when exposed to a magnetic field.

To put this in an understandable analogy, imagine two inflated balloons. One balloon is full of beans. When you rotate the balloon, the beans simply fall according to gravity — which is acting as the “magnetic field” in this analysis.

Now imagine the second balloon having all the beans glued to the inside of the balloon. When you rotate the balloon, they move with the balloon. It’s almost like a solid structure, except in this experiment, it’s a liquid.

Magnetic Liquid 3D Printing Properties

Berkeley Lab explains more:

“Among the magnetic droplets’ many amazing qualities, what stands out even more, Russell noted, is that they change shape to adapt to their surroundings. They morph from a sphere to a cylinder to a pancake, or a tube as thin as a strand of hair, or even to the shape of an octopus – all without losing their magnetic properties.”

Having the ability to produce magnetic droplets of this type opens up some very interesting possibilities. Essentially, these researchers have developed the means to create a construction toolkit for liquid structures and even machines.

Through ingenious thinking, it could be possible to develop all manner of microscopic devices that make use of this approach. They could be activated or powered through external or adjacent magnetic field generators, even enabling mobile microscopic devices that could perhaps alter their shape to, say, squeeze through small apertures.

Magnetic Liquid 3D Printing Futures

This seems to be the path the researchers are taking, as their next steps seem quite ambitious:

“Liu and Russell plan to continue research at Berkeley Lab and other national labs to develop even more complex 3D-printed magnetic liquid structures, such as a liquid-printed artificial cell, or miniature robotics that move like a tiny propeller for noninvasive yet targeted delivery of drug therapies to diseased cells.”

Once again, 3D printing technology has opened up an entirely new industry that eventually could be of huge benefit to society.

Via Berkeley Lab

A research thesis details the incredibly complex world of volumetric 3D printing. We review the highlights.