![3D printing parameters seen in Simplify3D [Source: Simplify3D]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb095432fb50.jpg)

A new strategy by some vendors to provide 3D printer profiles may backfire.

There’s a new strategy being employed by some vendors who hope to ensure more 3D print success and ease of use in the workplace: print profile libraries. Generally, this is a very good move, but there could be problems as things evolve into the future.

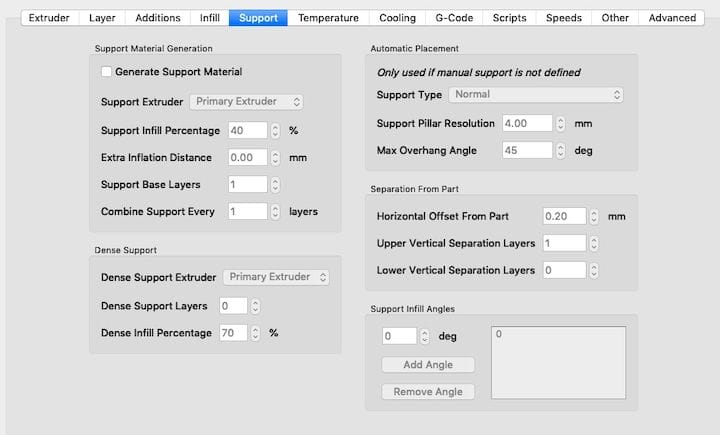

The idea here is that in order to achieve success for a given 3D print job, there will be an optimum set of 3D printing parameters. These parameters are a combination of literally hundreds of fields that instruct the 3D print slicing system on how to go about generating GCODE.

The parameters may have to do with temperature, speeds and feed rates, and could vary considerably over different layers, geometries and other factors. It can be extraordinarily complex to find the optimum set that can, time after time, produce quality 3D prints.

The first set of desktop 3D printers that emerged around a decade ago provided literally nothing. Operators had to somehow discover the best combinations of factors for their devices. This was made even more complex because most of the devices were kits that were assembled in slightly different ways by each operator.

Using 3D Print Profiles

Then manufacturers began to attach basic print profiles to their equipment. This greatly increased print reliability and enabled operators to get going far more rapidly than before.

However, there was a problem: print profiles are essentially a match between a specific machine model and a specific material. This meant that manufacturers would typically post profiles for their equipment only for very specific materials, usually their own or those from their close partners.

Of course, 3D printer operators wanted to and did in fact use all kinds of different materials from different materials vendors. Typically the materials from a 3D printer manufacturer, although certified, often have far less choice than is available in the wider market. This was particularly exacerbated with the introduction of countless new engineering materials used by professionals.

Now the problem was back at the manufacturers, who could not effectively sell into the professional market where they could not easily organize the right sets of materials and profiles to help their clients get printing.

Thus began a phenomenon that is still unfolding today: the introduction of print profile libraries. There are several companies now executing this strategy, with perhaps the most notable being Ultimaker. It’s actually a great idea, because it genuinely does help operators achieve success, or at least significantly reduce the probability of print failure.

Print Profile Problems

But there is a potential dark side to this approach.

How, exactly, do these print profiles get created? There are a couple of ways:

The 3D printer manufacturer could do so themselves in their lab. This would require materials vendors to send in samples, which would then be “dialed in” by experts to result in the print profile for that material. This is perhaps the most technically correct approach, but for the manufacturer it is quite expensive, as there is a constant and increasing flow of new and unusual materials to deal with.

User Submitted 3D Print Profiles

A second approach is to simply have the materials vendors — or any third party — submit the profile to the library. It’s in their interest to do so, as it could help materials sales, and is a lot less expensive for the 3D printer manufacturer. In most cases this could be a suitable solution, but there is the possibility that it could be wrong.

What if slightly off parameters were in the library for a material? What would the operators think after using them and finding flaws in their prints or even print failures? This is not a good scenario, as their trust in the entire print profile library would be compromised.

It seems that a hybrid approach should be used: third parties submit profiles to the 3D printer manufacturer, who then tests them to ensure they work properly. Only then should they be made available to the public in the library.

It is no doubt quite tempting for a 3D printer manufacturer wishing to “catch up” by quickly building a large profile library through the second approach, but in the end they may be causing harm to their users and to their brand.

Let’s all try to use the best 3D print parameters, shall we?

No one seems to offer collaborative 3D printing modes on dual extrusion devices. We explain why this is the case.