![[Image: Titan Robotics]](https://fabbaloo.com/wp-content/uploads/2020/05/TitanRoboticsDual2_img_5eb0974d768cd.jpg)

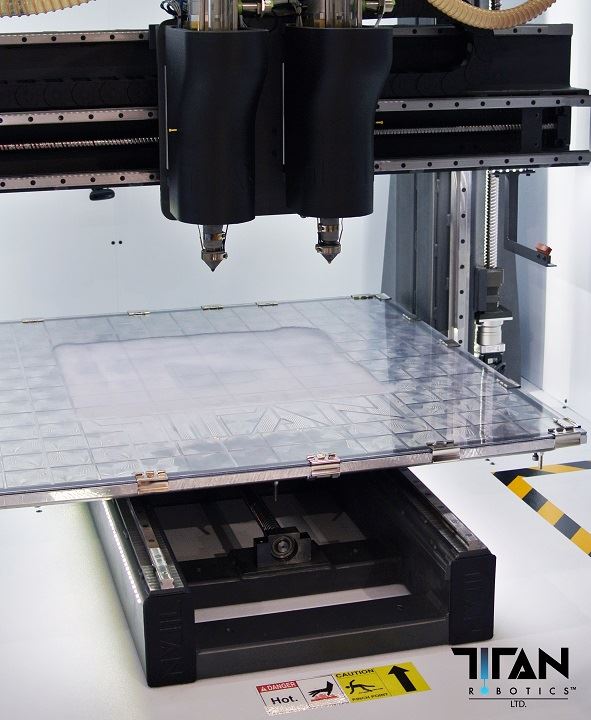

Titan Robotics is introducing its new Dual Pellet Extruder Atlas-H 3D printing system.

The new system builds upon the work the Colorado-based company has already introduced in terms of large-scale and pellet extruding 3D printing, offering dual extrusion capabilities.

Titan Robotics has long been interested in expanding cost-effective industrial solutions in 3D printing, and this new introduction is set to offer something highly interesting to the market.

The company says of the machine:

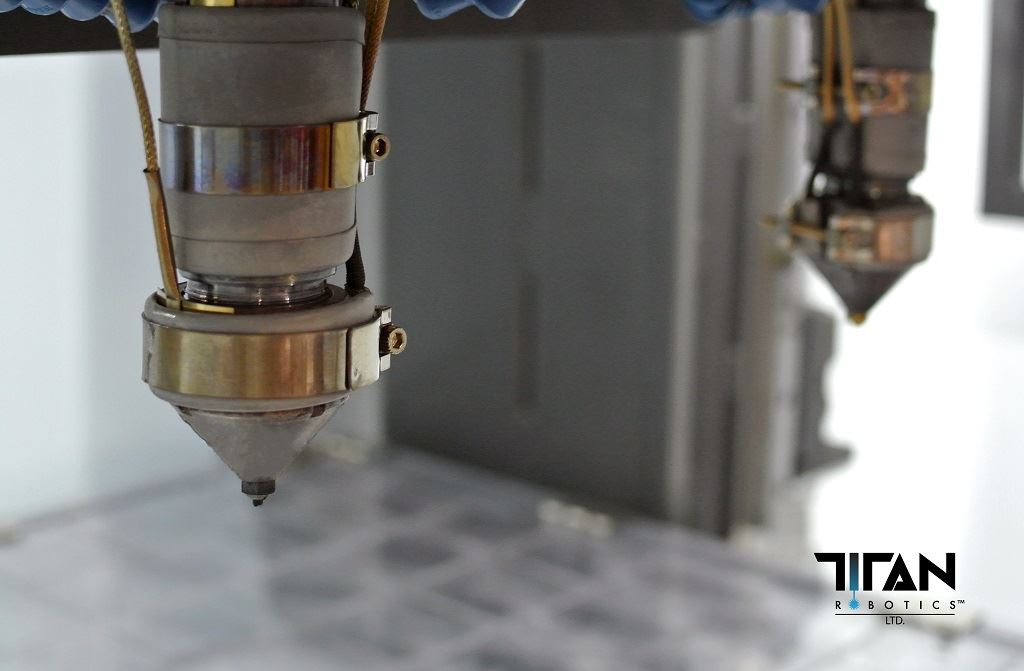

“The new Atlas-H product line features dual retracting pellet extruders combined with a robust frame and industrial closed-loop motion control system that enable print speeds reaching 30,000mm/minute. The Dual Pellet Extrusion System further reduces part production costs by combining high-speed printing with the ability to use a wider range of low-cost pellet feedstocks.”

The Atlas-H offers a 42” x 42” x 48” (about 1067 x 1067 x 1219 mm) build volume and is, Titan says, capable of reaching print speeds of up to a stunning 30,000 mm/min with multiple extruder heads on the same gantry.

Using a pellet extrusion system on the large-format Atlas with a heated enclosure enables a large variety of printable materials, including engineering-grade polymers. Because the material input is in pellet form, costs are significantly cut down from filament extrusion systems that require more expensive (and more processed) filaments.

The second pellet extruder also enables that ever more frequently seen capability to print with multiple materials, most often used for supports.

Materials companies are taking increased interest in 3D printing these days, as well. A few months ago, a chat with SABIC revealed that they were developing interest in large-format 3D printing, with Titan Robotics among named among the companies they’ve been working with. SABIC, mind, makes ULTEM materials and compatible supports, making them of great interest to industrial-minded 3D printing industry participants.

Also notable in this announcement is the ability for customers to make more personalized choices for their applications.

Machines from Titan Robotics have found use in a variety of uses, from automotive to foundry to defense to apparel, among many others. Each of these industries has unique requirements, and each participant unique needs to meet. Selecting a solution, particularly from intriguing equipment that offers options in configuration, helps 3D printing be an even more customizable solution.

“With the launch of Atlas-H, we believe both existing and new customers will benefit from increased speed and reduced raw material cost with high reliability never seen before in this industry. Our expanded product portfolio empowers our customers, enabling them to choose the configuration that meets their production needs. Available configurations include options for multiple filament and pellet extruders on a single gantry, thus optimizing customers’ capital investments and operating expenses,” said Titan Robotics CCO Rahul Kasat.

The Atlas-H Dual Pellet Extrusion 3D printer is making its debut this week at RAPID + TCT, where it will be printing live at Titan’s booth (527).

Via Titan Robotics

WASP has modified their popular Delta 2040 3D printer to enable 3D printing of high temperature materials like PEEK. But there’s another surprise, too.