![A filament-tracking device for 3D printers [Source: Spul]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0991ff3dc4.jpg)

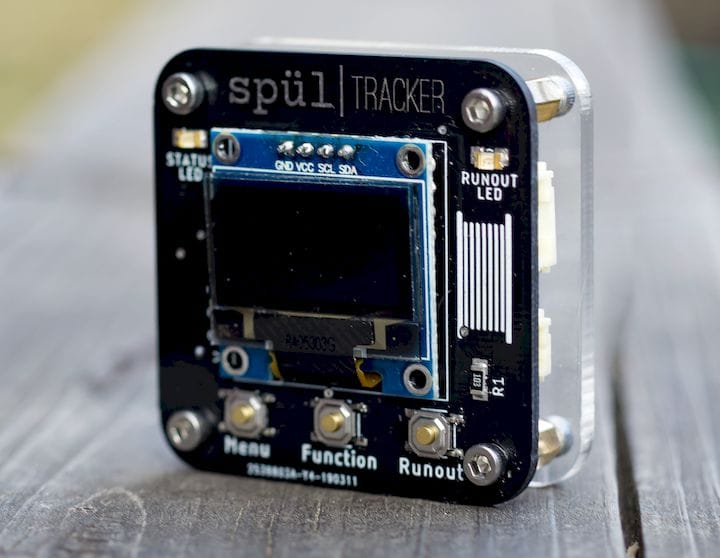

There seems to be a very interesting 3D printing accessory in the works, the “Spül Tracker”.

The Spül Tracker is a small device that attaches to the filament path and provides extensive monitoring services. The idea here is to ensure that the 3D printer operator is fully aware of the precise amount of material available.

For filament-based machines, managing input material has been a persistent problem for virtually the entire lifetime of these devices. 10 years ago, when I first began operating my own 3D printers, one of the major problems of the day was an inability to know whether a given print could be successfully completed with the material left on the filament spool.

Basically, you had to guess. I recall many times holding up a partially-used spool and trying to imagine that remaining volume of material bent into the shape and size of the object I hoped to print. Would there be enough? Or should I swap the partially-used spool for one with more material?

Today, many years later, the problem still remains. Few desktop 3D printers have any sort of mechanism for handling the situation. Some machines may have a “filament-out sensor”, but that really is for damage control after your guess was wrong.

Now we see hints of the coming Spül Tracker. There’s not a lot of information, as it has not been officially announced, nor released. But we can tell from their website is that it’s comprised of an encoder that precisely monitors the passage of filament towards the 3D printer.

As filament passes through the Spül Tracker, the encoder clocks up a running total length. The device connects by WiFi and allows display of this information through an online interface.

The Spül Tracker seems to physically track only the length of filament passing through. However, they say:

“With one of the 10 preset or custom material density profiles and the length data SPÜL receives from the Tracking Unit, we can calculate the weight of the filament used to the hundredth of a gram.”

![What you get from the Spül Tracker [Source: Spul]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb099204a4a6.jpg)

Thus in theory the Spül Tracker will tell you both the length and weight of filament consumed since its previous reset. By subtracting these values from the expected capacity of the input spool, one could instantly compute the theoretically precise amount of material remaining.

They don’t say, but it would seem logical that their online interface should be able to do this subtraction for you automatically, if you were able to input the original spool size.

In addition, the Spül Tracker also includes a “Runout Detector”, in case your 3D printer does not have one already installed.

All of this sounds truly excellent, but I fear there is one problem lurking that may cause issues with the Spül Tracker.

And that is the answer to this question: how much material is REALLY on that spool?

We purchase spools typically by weight. For example, you might purchase a 1kg spool of PLA white. There’s likely close to 1kg of material on that spool, but not exactly 1kg. I suspect that some producers may short the spool slightly, while others overrun the capacity slightly to ensure that the client never receives less than the stated amount.

In either of these cases I can pretty confidently say that an accuracy of 0.01g is far less than the variability in actual spool capacity.

![The Spül Tracker, filament-tracking device for 3D printers [Source: Spul]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb099208b5bf.jpg)

Nevertheless, the Spül Tracker Will almost certainly be an incredibly useful device that will probably pay for itself the first time it causes you to avoid a disastrous run-out scenario.

I say “probably” we don’t actually know the cost of the Spül Tracker yet. The folks behind the device will probably launch a Kickstarter campaign or similar in coming weeks or months.

Via Spul

An Austrian company has developed an incredibly sophisticated end-to-end automation system for metal 3D print post processing.