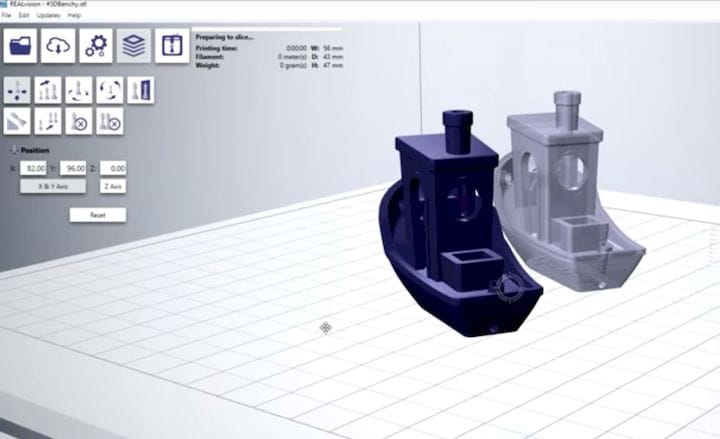

![The REALvision 3D print slicing system [Source: Create it REAL]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb098a5186e5.jpg)

I’m looking at another 3D print slicing software option, REALvision.

REALvision is a product of Denmark-based Create it REAL. The company focuses on providing solutions not directly for 3D printing buyers and operators, but rather for 3D printer manufacturers.

Their product line includes a number of items, the most notable of which is a controller board that is capable of driving a 3D printer at extreme speeds. Several manufacturers have incorporated this technology into their device and have been able to market devices that can, at least in theory, print at speeds up to 400 mm/s. I’ve seen some of these machines in action and they are indeed quite fast.

Since the introduction of their controller board, Create it REAL has introduced several other products that are also quite interesting. One of them is an encryption system for performing secure 3D printing. The heavy processing required to do the decryption is of course provided by their fancy controller board.

They have another product that I hadn’t previously noticed, REALvision. This is a slicing system that seems to offer some interesting features. It is a software program used to prepare 3D models for printing by producing GCODE.

There are several slicing programs on the market today, and all of them face a battle between ease-of-use and the incredible complexity of 3D printing, which can sometimes involve literally hundreds of different printing parameters.

From what I can see, REALvision handles this challenge very well, and might even have the most straightforward interface I’ve seen in 3D print slicing programs. Of course, it handles all the basics of slicing, including loading STL models, positioning, resizing, orientation, and generating GCODE.

![Incredibly well-done tool tips in REALvision [Source: Create it REAL]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb098a5657a9.jpg)

But it seems to handle the more advanced aspects in a most friendly manner. Here, for example, we see what could be the best tooltips I’ve ever seen in a 3D print slicing program. Not only does it tell you a description of what the parameter does in some detail, but it even shows you a picture of what it does!

It seems that most of the parameters have this capability.

It also provides what seems to be an understandable method of saving parameters and managing printers. For some reason this is sometimes very challenging for other 3D print slicing systems, but Create it REAL seems to have figured out how to do it in a way that everyone could understand.

REALvision also provides a printer logging function, something that is quite absent in most other slicing systems. For anybody doing more than casual 3D prints, this is almost an essential requirement. You need to know what you’ve done.

REALvision seems to include three modes: easy, advanced, and expert, while most systems have only two. Here the “expert” mode is used for functions that are only available on specific printers. This means that one could more easily manage a group of unlike 3D printers, since the majority of the interface would be identical regardless of device.

Of course, REALvision is set up to handle all of the company’s advanced functions, in particular their high-speed controller board.

![[Source: Create it REAL]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb098a5b3bc9.jpg)

Another fabulous feature is an integrated troubleshooting guide. This feature includes visuals of common 3D printing problems, and would allow an operator to more rapidly diagnose an issue. This would be of particular interest to those new to 3D printing.

These are all features I’d like to see every 3D print slicing system.

Can you use REALvision? Not directly, as it is our understanding the company intends on primarily selling the product to manufacturers for them to bundle with their machines. However, the features on this product are so appealing that I’m wondering whether Create it REAL would consider offering it as a standalone product to the public.

Via Create it REAL

Teton Simulation has now integrated their FEA algorithm directly into Ultimaker Cura, vastly simplifying and empowering 3D printing workflows.