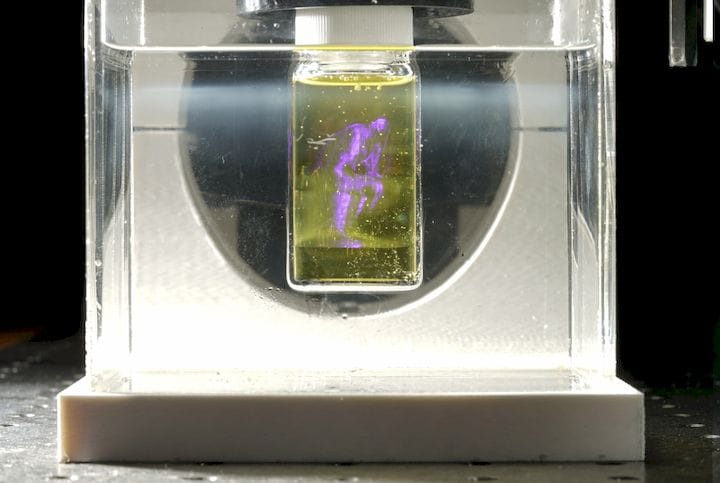

![The CAL 3D printing process in action [Image: Adam Lau/Berkeley Engineering]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0993bdde48.jpg)

I’m reading an interview with one of the inventors of the CAL 3D printing process, and it seems it could be the most rapid 3D printing process ever.

If you’re not familiar with the CAL 3D printing process, we wrote an introduction to it a few months ago. It’s a new process developed by researchers at the University of California, Berkeley that is radically different from other 3D printing processes, and could become a standard among manufacturers in the future.

In brief, the resin-based CAL process, or “Computed Axial Lithography” works like a CAT scan in reverse. Like DLP 3D printing, it uses a projector to selectively focus light energy into a tank of liquid resin. But that’s about where the similarities end.

The trick with CAL is that the resin chamber is rotated, meaning the active area within the liquid that’s being solidified is constantly changing, unlike DLP or SLA systems where there is a formally defined layer at the bottom of the resin tank that becomes solidified.

CAL instead fires low energy deep into the center of the resin tank, right through the liquid. As the tank spins different areas of the object are exposed and gradually solidified. There are no “layers” as such, and the object grows from the inside out.

There are multiple advantages inherent in this approach, some of which we wrote about in our previous post. However, the piece in The Engineer reveals quite a bit more. UCB Assistant Professor of Mechanical Engineering Hayden Taylor explains, for example:

“The process takes anywhere between 30 seconds and a couple of minutes to print an object. We have printed structures ranging up to between 5 and 10cm in diameter, and with features down to about 0.3mm. Existing methods like stereolithography would take multiple hours to print similar objects.”

It seems that this is a very rapid process for 3D printing, far faster than other resin processes, even those used by industry leaders like Carbon.

And:

“Another positive about oxygen inhibition is the clear route it provides to regenerating unused resin. Following the printing process, any unused resin can be drained out of the volume and exposed to air to allow the oxygen content to reach its original equilibrium state once again. The thresholding behaviour is reliably recovered and the resin can be reused, reducing material wastage.”

I wasn’t aware that resin “wears out” in this way, but this could be a way to perhaps ensure higher-quality prints.

And:

“The rough edges associated with the layer-by-layer printing of standard additive processes are literally smoothed out. By essentially printing whole objects in one go, no layering is needed, which translates to no ridges and smoother builds, which are ideal for consumer products.

We’ve printed soft structures with exceptionally smooth surfaces into gelatin methacrylate hydrogel. By printing an entire object concurrently, our method also eliminates the need to design and build solid support systems or scaffolding, even for overhanging features. We can print into high-viscosity fluids which inherently support the object being printed, translating to less post-processing time in the removal of supports.”

This suggests that the quality should be very high on prints produced with CAL.

And:

“As the object is not moving relative to the liquid during printing, it is not limited by fluid flow, which means that we are able to use CAL to print into materials that have a higher viscosity, broadening the range of material properties that can be accessed. By avoiding fluid flow during printing, we can even print into very soft and delicate materials, like the gelatin methacrylate, which may open new applications in bioprinting of soft tissues.”

This is quite important, as it could open the way for highly unusual materials: current resin-based 3D printing processes require relatively low viscosity liquid resins to allow for flow, but this development could mean many more types of resin materials could be deployed with CAL.

And:

“ In CAL, light passes all the way through the printing volume and is absorbed at a far gentler rate than in traditional light-based printers. We anticipate that this property means that we will be able to scale up the size of printed objects by increasing the power of the illumination source, without necessarily greatly increasing the printing time. Using a simple model that extrapolates from our existing experiments, we anticipate being able to print a 0.5m diameter part with features down to 0.1–0.2mm, while processing material at several litres per minute.”

Thus they should be able to scale up the system to much larger build volumes. They also suggest that by using lenses to spread out the projector pixel beams they could reach much larger volumes.

When you have a new 3D printing process that is much faster, is high-quality, uses more materials and could scale up to large sizes, I think we have a winner.

Via The Engineer

A research thesis details the incredibly complex world of volumetric 3D printing. We review the highlights.