![How to create a makerspace [Source: Amazon]](https://fabbaloo.com/wp-content/uploads/2020/05/creating-a-makerspace_result_img_5eb09a0f3c8b6.jpg)

This week’s selection is “The Makerspace Workbench: Tools, Technologies, and Techniques for Making” by author Adam Kemp.

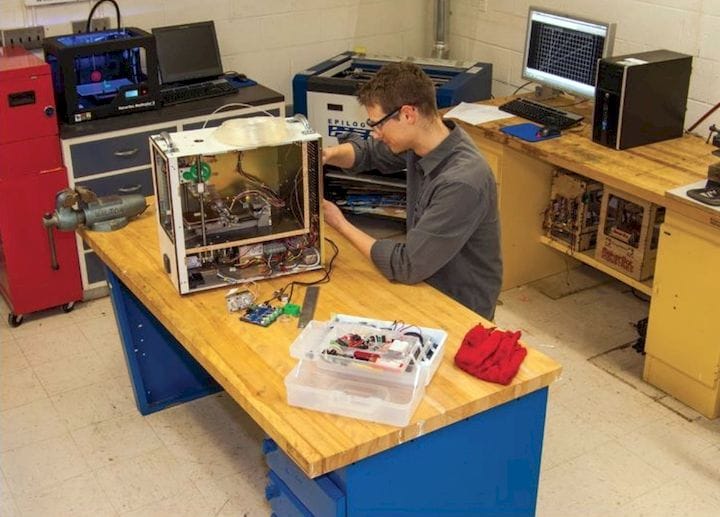

This book investigates the practical manner of setting up a basic, yet powerful makerspace. A makerspace is a physical facility in which a variety of making equipment is provided to a community. The key to a successful makerspace is ensuring the machines are easily accessible.

Author Kemp reviews the process of establishing a makerspace in a number of dimensions, well beyond the mere equipment. Yes, the equipment is important and obviously the core of any makerspace, but to ensure they’re operating at full potential many other aspects must be carefully considered.

Electrical power, including capacity, reliability, quality and distribution is critical, as are ventilation systems when certain types of equipment are chosen. The physical location is also of great importance, as it will largely determine the feasibility of executing different types of projects. For example, a location with poor access might discourage users from projects involving larger sized parts and supplies.

Of course, the book contains copious amounts of detail on all the possible types of equipment one might consider installing in a makerspace, ranging from basic woodworking and metalworking tools to more advanced topics, such as electronics and 3D printing. The message here is that there are decisions to be made to ensure the equipment matches the goals of the makerspace project.

Makerspaces are placed in many different venues, both public and private. A frequently seen category in recent years has been the library makerspace, but it’s also possible to install them in other locations, including as a standalone operation. For that, the book even recommends an approach for soliciting donations. But as someone who’s launched a makerspace, I can say confidently that things always cost far more than originally anticipated.

I cannot emphasize how important the non-equipment issues can be in a makerspace. Even the placement of equipment is very important, as their locations will determine much of the possible workflow. Fortunately, Kemp’s book reviews most of these aspects.

One reason I’m so interested in this book is that it could be of surprising use to larger corporations. While you might think the makerspace concept is “something for those maker people”, it is definitely not. Some say that “everyone is a maker”, and while I disagree with that statement, there are very substantial numbers of highly creative people who have yet to realize their making potential.

Some of these hidden creatives are located deep within big companies, and the companies could benefit if some of their creativity was unleashed.

There’s no better way to do that than to open a “corporate makerspace”. This would operate in a manner similar to a library makerspace, but be available to employees.

In such a space staff could literally create job aids that could make their work more efficient, or, if replicated, many others, too. But even if they do not succeed, their creativity is unleashed and they’ll think a bit differently about work from then forward, hopefully rubbing off into their normal work activities.

But you need a makerspace. Everyone needs a makerspace. Read this book to find out how.

Via Amazon

This week’s selection is “3D Printing Projects” by Dorling Kindersley, a.k.a. “DK”.