![A new process for 3D bioprinting skin onto live patients [Source: Nature]](https://fabbaloo.com/wp-content/uploads/2020/05/bioprintskin-ov_result_img_5eb09bb683fce.jpg)

A paper in Nature describes an incredible method of 3D printing live skin to rapidly secure wounds.

There have been plenty of bioprinting applications, but this one seems to have a ring of extreme practicality about it. Researchers led by James Yoo, M.D., PhD at the Wake Forest School of Medicine developed a proof of concept mechanism that can literally 3D print a custom skin graft onto a patient far faster than current techniques.

The type of injury being resolved in this case is a surface wound where a larger area of skin is removed. Cuts, on the other hand, need only to be stitched together and nature heals, well, naturally. But when the skin is removed through mechanical or chemical means or through burns, a frequent type of accident, you can’t simply stitch up the patient.

Today the current practice is to undergo a series of expensive procedures to remove skin from elsewhere and graft it onto the wound. Eventually this will heal over. However, this practice is time consuming, expensive and the results are not always suitable for the patient.

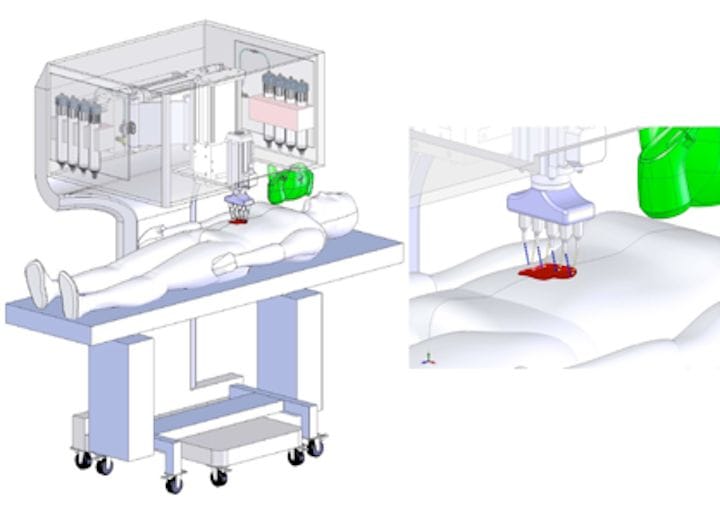

The researchers developed an end-to-end process in which a custom skin layer is 3D printed onto the live patient in a way that precisely matches the wound’s geometry.

The process for accomplishing this is quite fascinating. First, a 3D scan is obtained of the wound by using a handheld 3D scanner. These 3D data are then input to Geomagic Studio to create a proper 3D representation of the wound and in particular the geometric volume to be filled with new skin.

The resulting 3D model is used to generate toolpaths for the 3D printer, which in this case is a bioprinter having multiple syringe-style extruders mounted on a robot arm. There are multiple extruders because there is more than one material used to create the skin itself.

![The bioprinting method follows the contours of the patient [Source: Nature ]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09bb6d0685.jpg)

The generated toolpaths follow the contour of the patient, who, I suspect, must be rigidly held still during this entire process. The different materials are deposited in a way that mimics actual skin construction. They explain:

“Integrated imaging technology facilitated the precise delivery of either autologous or allogeneic dermal fibroblasts and epidermal keratinocytes directly into an injured area, replicating the layered skin structure.”

![Example of a wound closed by the 3D bioprinting system [Source: Nature ]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09bb71bb84.jpg)

But does this actually work? They explain the results:

“Excisional wounds bioprinted with layered autologous dermal fibroblasts and epidermal keratinocytes in a hydrogel carrier showed rapid wound closure, reduced contraction and accelerated re-epithelialization. These regenerated tissues had a dermal structure and composition similar to healthy skin, with extensive collagen deposition arranged in large, organized fibers, extensive mature vascular formation and proliferating keratinocytes.”

They say that the 3D printed skin demonstrated more rapid wound closure as compared to either untreated or those using conventional therapies, sometimes with substantial differences in healing. They found that the 3D printed wounds would completely close over an average period of three weeks versus the normal five weeks using conventional approaches.

The best part of this proof of concept is that the machine and process are far smaller than what would normally be used, which requires hospitals, multiple procedures and more. It seems while the system is not literally something you could pick up yourself, it is essentially portable and thus could be used anywhere. The authors of the paper even point out that the equipment is slim enough to fit through a normal doorway.

This means future production systems using this concept could be deployed widely, allowing, say, burn victims to very quickly service their wounds and dramatically reduce their suffering — and costs.

In the world of 3D printing much is said about the ability to get mechanical parts made more quickly; here we see the same phenomenon, but it is HUMAN parts instead of mechanical parts. Progress!

Via Nature

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.