![A new glass 3D printing process? [Source: @AuManufacturing]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09b20a7d68.jpg)

Researchers in Australia seem to have developed another technique for 3D printing glass.

Glass has long been a desirable material for 3D printing, yet there has not been a commercially successful implementation. Some experiments have been able to slowly extrude rather coarse flows of glass to form simple geometric objects, and others have used the composite approach by embedding glass particles in otherwise printable binders and sintering after the fact.

The new Australian process is being developed by Nick Birbilis and Darren Feenstra, but we don’t know much about it. According to a report on @AuManufacturing:

“Feenstra declines to say much about exactly how their extrusion printer works, but says it addresses the difficulties of forming glass, where the temperature each step of production must be carefully managed.”

However, the report hints that precise control of temperatures are employed in the mysterious process, with the build chamber being heated to a sweltering 700C. Feenstra explains:

“You have to print in a chamber at a controlled temperature, so we’re printing into a chamber that’s controlled around 700 degrees, because we don’t want it to crack, and then we have to anneal it afterwards.

“The phase transformation is very complex, as it goes from a solid into annealing temperature into a working temperature to the glass transition temperature, before it even gets to a liquid. The thing we needed to get our head around is that we needed to really optimise the amount of heat we put into the system, to give us the window and the flexibility to operate across all those temperatures.”

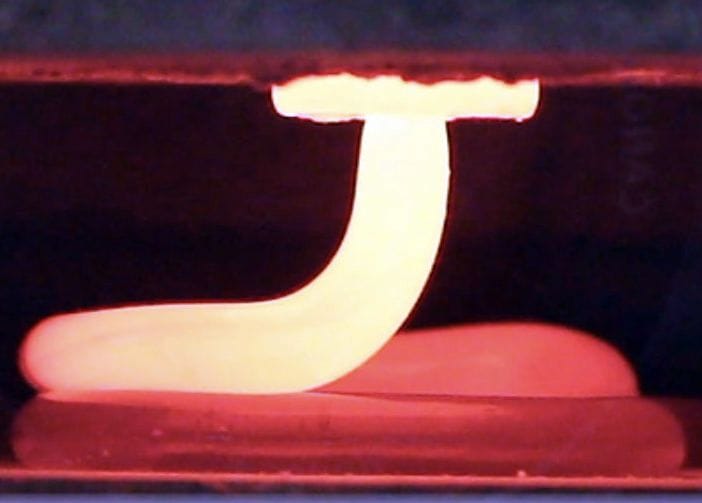

We’re hoping this new process is able to 3D print more complex 3D geometries than other pure glass 3D printing processes, although this may not be the case based on a peek at the extrusion process shown at top from @AuManufacturing: the extrusion appears to be rather thick, which would limit the possible printable geometries.

They say they have a goal of a 0.6mm layer size, which would place the technology within reasonable comparison with traditional thermoplastic 3D printing processes. If they can achieve that standard, then it could open up many more usage possibilities.

They have smartly patented their process, thus potentially gaining a key advantage in the market should they eventually produce a commercial product.

If they’re successful, we could see some very unusual uses in industry and artistic endeavors. However, there will also be a significant challenge.

That challenge is the same faced by thermoplastic and metal 3D printing companies: persuading the existing users of traditional making processes to make the switch to 3D printing.

In other industries this has been a considerably difficult challenge, as successful companies tend to not want to change their business approaches. This has taken massive investments, deep infiltrations into industry and ingenious marketing approaches to succeed. It’s worked in automotive, dental and aerospace industries, but only after many years of effort.

The same level of effort may be necessary for the introduction of glass 3D printing. In fact, the glass-making industry has had relatively few technological innovations in the making process for decades, making the prospect of change even more steep.

Finally, I’m wondering if Australia is now becoming one of the world’s hotbeds for 3D print innovations, as we’ve now seen several very innovative approaches emerge from that southern country, such as Aurora Labs’ bulk metal 3D printing process.

Via @AuManufacturing

A research thesis details the incredibly complex world of volumetric 3D printing. We review the highlights.