![[Image: Jessica Hughes]](https://fabbaloo.com/wp-content/uploads/2020/05/20180313_1505591_img_5eb09a652d71d.jpg)

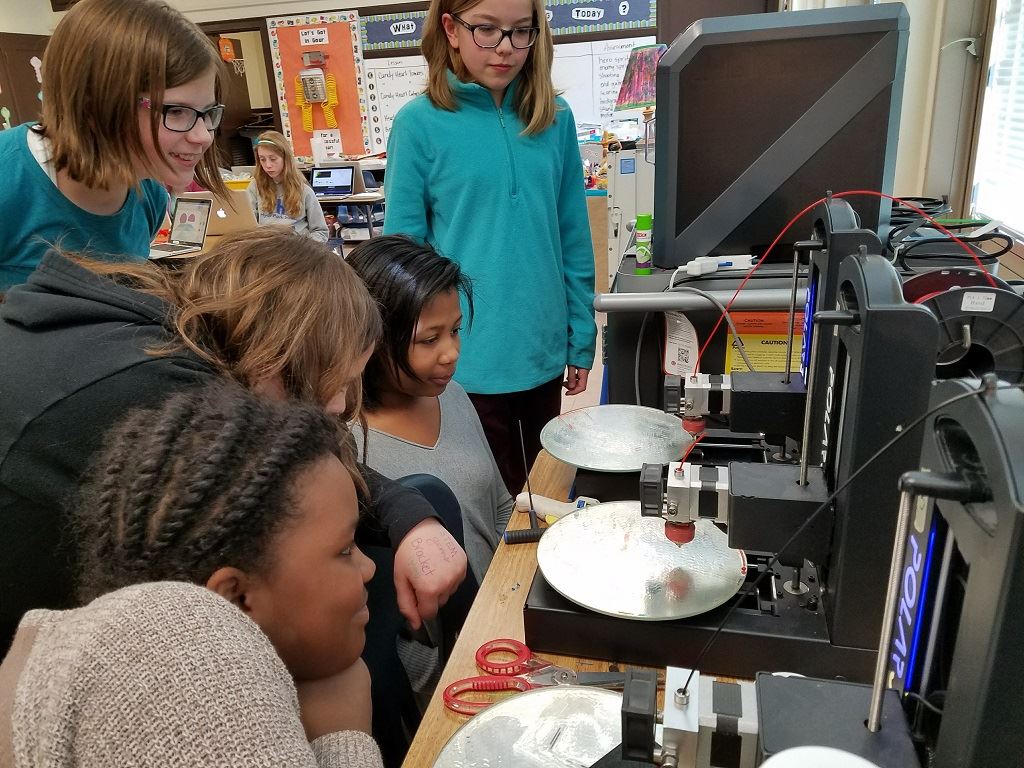

A Girls 3D Print Club in Cincinnati, Ohio helps highlight STEM opportunities for students.

GE Additive’s dedication to education is helping students of all ages gain access to 3D printing. Jessica Hughes of Hyde Park School is a teacher who is herself dedicated to that same mission. One of the early participants in the Additive Education Program (AEP), working with 3D printers in her classroom through the program since its 2017 launch.

Early on, Hughes noticed something, though: the boys in her classes had already had some exposure to and experience with 3D printing. The girls had some catching up to do. This disparity isn’t at all uncommon in 3D printing or other STEM subject areas, and many initiatives are arising to address this from an early age. So Hughes started a Girls 3D Print Club to encourage the girls to go hands-on with 3D printers.

Hughes shared more of her experiences in working with 3D printing through AEP for the last two years in a Q&A GE Additive has shared with us.

What have been some of the highlights of being part of the program?

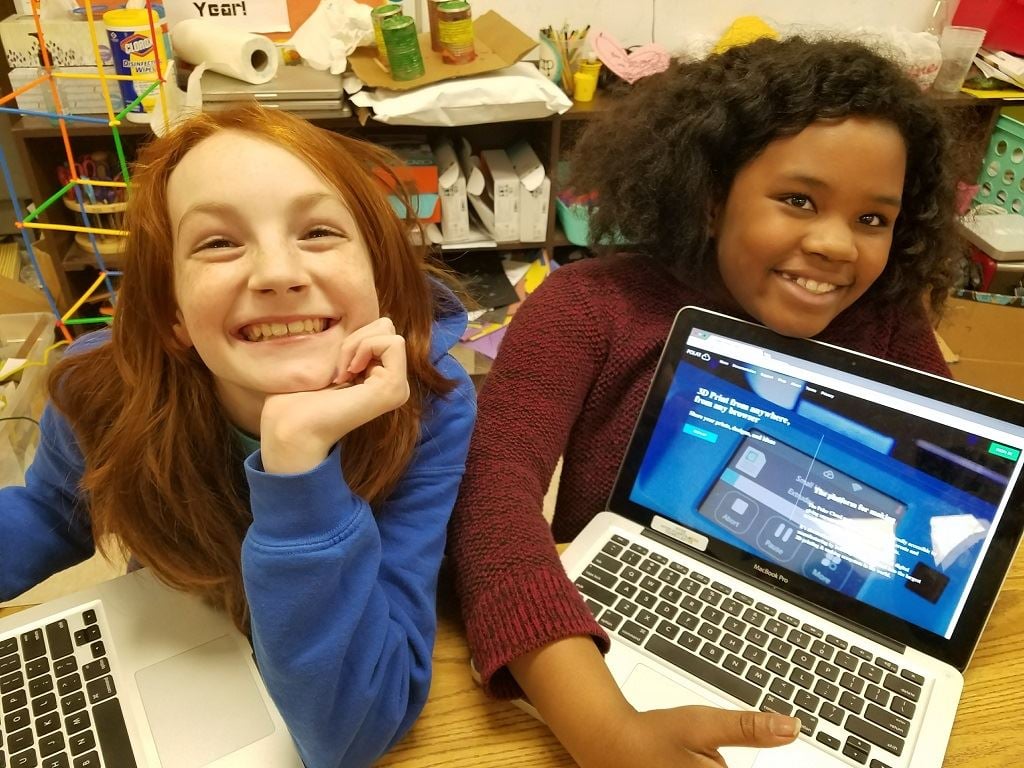

“For me, the best part has been having access to the curriculum that GE Additive has provided through the Polar Cloud. When I started teaching STEM almost three years ago, I had these 3D printers sitting in my room that I had no idea what to do with. I decided to jump in and give it a try but was left wondering how to teach children effectively, and how to connect additive technologies to real world problems, that they could understand and relate to.

I received the GE AEP grant & gained access to STEAMTrax curriculum on the Polar Cloud and that’s when it all clicked. We started with the ‘Tinkering with Turbines’ unit and my students blew me away, not only their innovative designs, but their research and understanding of alternative energies and their impact on the environment.

Using CAD design, and 3D printing skills, this curriculum encourages students at approach a problem in a systematic way. They start by identifying a need, visualizing solutions, and generating ideas. They send their creations to the printer and then evaluate and improve their designs. They are actively collaborating, problem solving, and overcoming obstacles as they follow the steps of the engineering design process. This is what STEM is all about.”

Could you explain how you’ve integrated additive and 3D printing into your lesson plans and wider STEM teaching at the school?

“My students start learning the basics of CAD design & how additive manufacturing is changing the way industries make parts for everything from planes to homes to human organs. From there, we learn about how 3D printers work and what prototyping is and why it is necessary in the design process. Next, we move through some simple challenges.

Designing and 3D printing things like jack-o’-lanterns, bubble wands, napkin holders, & marble mazes allows them the opportunity to experience moving from abstract to concrete using CAD design while also learning to manipulate print settings in the Polar Cloud.

After winter break, we begin to apply the skills we have learned to real world problems. We also move away from printing a single product to parts. This is where the STEAMTrax curriculum comes in.

However, my students also use what they have learned to design and print things for their core classes as well. They have created models of the Ancient Egyptian pyramids for a social studies class project, dice for math games, models of cells for science and a scene from a book for a book report in reading. When it comes to teaching additive to kids, the possibilities are endless.”

[Images: Jessica Hughes]

How have you tapped into the AEP community – what can new schools expect, how should they engage?

“The AEP group on Facebook has been a great addition this year. I have enjoyed hearing from other schools about what they are teaching and seeing projects from students around the world.

Having a place to share ideas, get feedback, troubleshoot, and grow as teachers has been so beneficial. I learned about new projects such as the coral reef rejuvenation project that is underway in Florida where kids can 3D print coral models and donate them to be installed in the Atlantic Ocean.

My students are so excited to participate. Group members are so supportive and welcoming. It is a great place to collaborate and learn from other educators in the program.”

What is the most complex part the students have printed… and the strangest?

“The most complex part I have had a student print was a drone body. We purchased a drone kit for our after-school drone club & decided to try to design, 3D print, & assemble a drone that we could fly. The drone parts had to be fitted with precision. This made it difficult for the students to print an accurate model.

As one of them stated,’Mrs. Hughes, I had no idea there was going to be so much math in this club. It’s ok though. I’m not quitting. I like math.’

They eventually got the parts to fit & we flew the drone for all of three seconds before it crashed to the ground and broke into 17 pieces. They said they wanted to see if there was rubber filament for next time.

The strangest print we have ever had was a condiment device that would leave no drop of condiment behind. It was called the ‘Mayo Master.’

It was the brainchild of one of the students in my all Girls 3D print club, sponsored by Greater Cincinnati STEM Collaborative, during our Inventor’s Challenge.

The students were challenged to come up with an invention that solves a problem they or someone they know faces on a day to day basis. This child was bothered by the amount of mayo that was left in the bottle when it stopped pouring out of the spout.

She went through about 14 iterations and worked so very hard, but the mayonnaise never cooperated with her device. It was a difficult process for her and there were tears, but she learned a lot about failing forward and how to take each misstep as a learning experience and grow from it. I have no doubt that she will one day redesign condiment containers for a large corporation.”

How have you grown as an educator?

“Learning 3D printing with elementary students has given me more confidence to try new things. I began this journey three years ago knowing absolutely nothing about additive manufacturing, CAD design and 3D printing.

My students & I have grown together as we learned persistence and problem solving through 3D design and printing.

Rather than leading lessons and delivering content, I have become a facilitator of makers.

It is awesome to see their faces light up when they create something from nothing and then get to see it being produced right before their very eyes. It is so empowering for them and for me.

I want to continue to teach in such a way that ignites the imaginations of my students and allows them to express their ideas in meaningful ways. This journey has been amazing for both me and my students.”

![[Image: Jessica Hughes]](https://fabbaloo.com/wp-content/uploads/2020/05/20180206_1524251_img_5eb09a66903bf.jpg)

What’s next for Hyde Park School?

“Next year, we plan to expand our curriculum to include some of our younger students. They see the 3D printers in action every day & they want to learn how to make things too.

They ask me questions about how the printers work & what they are printing all the time. They often ask when they will get a chance to 3D print something. I would love to introduce the magic to them at an earlier age.

They are so eager & have such a great capacity to adapt to new technology very quickly. I know they will make some amazing things if given the opportunity.

Beyond the STEAM Lab, we want to find more opportunities for our students to use what they have learned to help impact their world. Projects like ‘Tinkering with Turbines’, ‘Creating Coastal Barriers’ and ‘Constructing Earthquake Resistant Structures’ have empowered my students to see themselves as problem solvers.

We want to keep that going because teaching young people to see themselves as makers helps them develop the sense that they can change the world. How cool is that?”

AEP is fully focused on primary and secondary schools — grade levels where they have already placed 3D printers in more than 600 schools — for the next iteration. It’s still accepting applications for another few days; the deadline is Monday, April 1.

Via GE Additive and Hyde Park School