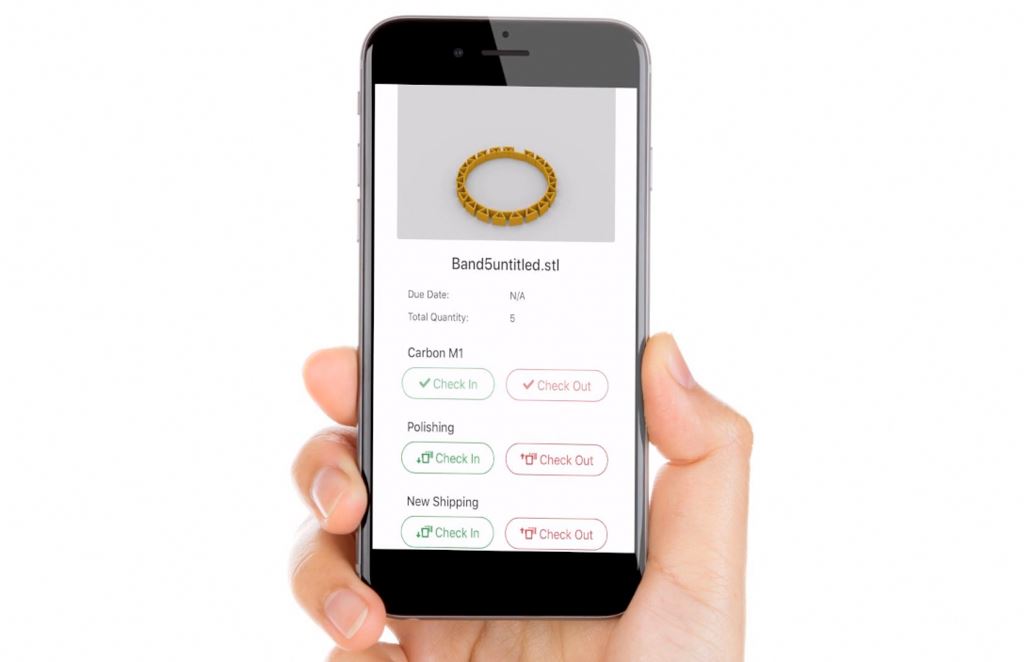

![[Image: Authentise]](https://fabbaloo.com/wp-content/uploads/2020/05/AppScreenshot1_img_5eb09ab6220db.jpg)

Authentise has announced a new app to extend the digital thread in additive manufacturing.

Available soon as a trial release in the Google Play store and online, the app is intended to ease the end-to-end process of digital manufacturing. Which, it turns out, isn’t always terribly digitized.

“Despite the fact that additive devices are nearly entirely digital, the entire process is far from it. Our software already retrieves data from more additive devices than anybody else, as well as some post processing tools, but that’s not enough. Manual process steps are tedious enough for operators; reporting their progress shouldn’t be. By releasing this app, we’re simply doing what we always do; focus on making the life of the operator easier. The fact that we’re using the data generated to add further value is just added bonus,” says Authentise CEO Andre Wegner.

The ever-popular QR code system is coming into play. Such codes can be implanted on travelers so operators can “move parts through manual post processing stages such as powder or support removal, inspection, testing and more,” Authentise relays.

End-to-end management and tracking is increasingly critical as 3D printing continues to move more directly into end-use products. Serial production is a major undertaking, and aside from actually making quality parts and products is accurate knowledge of just where those parts are and when they’ll be moving into the next phases.

Traceability is a large concern, and software companies in the additive manufacturing space are honing in on solutions. Other efforts, from such companies as Identify3D and LEO Lane, focus on traceability and authenticity in the supply chain; hardware companies are also cottoning on to the importance of traceability. These solutions tend to involve QR codes on the 3D printed objects themselves and focus on security and IP concerns.

For Authentise’s app, the QR codes are found on travelers. The company has also released a “minimalist traveler that allows additive manufacturing facilities to start the process of going completely paperless.”

Travelers, or manufacturing instructions, travel (aha) along with each part as it is made, offering detail on procedures, materials, and steps involved in its creation, along with part name, number, and description; relevant dates and quantities; and other part-specific data. Going paperless should ease up on the 2D printing involved in this part of the manufacturing process.

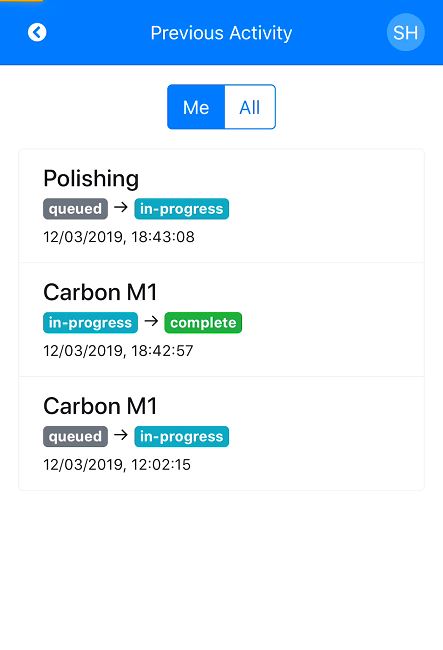

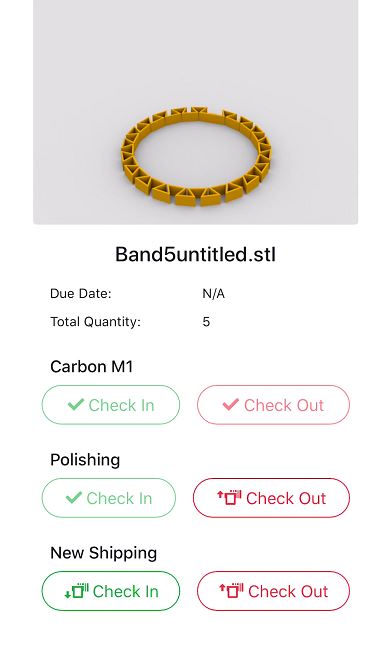

A look at the app from Authentise:

The Authentise app is in early days, but already has more functionality in store. The data from the app can be used with Authentise’s Machine Learning algorithms to enhance estimates of timing and quality. Future releases are set to include attachments (e.g., images, notes) for production steps as well as granting specific permissions to operators to tweak process steps.

3D printing is an important part of the digital manufacturing workflow. Digitizing that workflow is taking a step toward a more completely digital digital manufacturing experience.

Via Authentise