![New metals from Markforged [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09c2ba21aa.jpg)

It looks like Markforged will be releasing some new metal materials soon.

The company got its start by developing a 3D printer that has the unique ability to embed a continuous filament of carbon fiber into a 3D print, which otherwise would be made from nylon or similar strong materials. The carbon fiber feature drew quite a few clients to the company.

But while the company has continued to successfully market the carbon fiber equipment, they also branched out into metal 3D printing with the introduction of a cold printing process. The Metal X is the machine, and its process is a lot less complex than traditional metal 3D printers.

At the time of its introduction, the Metal X faced competition primarily from powder-bed laser systems, where a powerful laser would selectively melt a flat bed of fine metal powder. These systems have been around for years and are quite mature. They produce high-quality parts and are now extensively used in aerospace and automotive industries.

However, they are quite expensive to operate, mainly as a side effect of the fine powder used, which requires highly specialized handling.

Markforged’s process is different. Instead of powder, they use a proprietary filament that’s significantly infused with metal powder. This is 3D printed in the same manner as any other extrusion 3D printer, producing a green part made from metal powder and binder.

Subsequent post-processing steps debind the print and sinter the metal particles together to result in a proper metal part.

The cold process doesn’t involve powder, and thus is markedly easier to handle and significantly reduces costs of metal 3D printing.

The catch here is that in order to use the Metal X, you must use their proprietary filaments. Up to now they’ve offered only two metal materials: 17-4 PH Stainless Steel and H13 Tool Steel. These are quite useful, but sometimes other metals are desired.

Never fear, it seems that Markforged is about to release more materials. On their website you can see they intend on releasing the popular 316L Stainless Steel, but we learned they have more in mind.

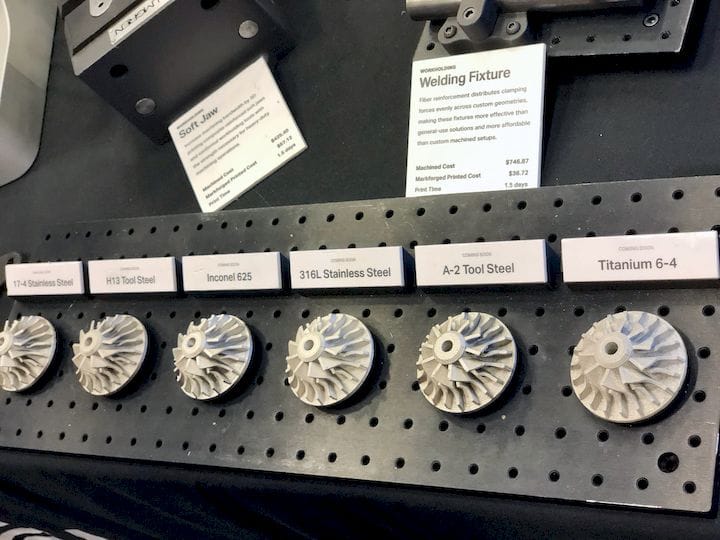

At top you can see an image of a display we recently saw at a Markforged event. It seems in addition to the three metals mentioned above, they are also intending to release:

-

Inconel 625 — a high-temperature steel that’s very strong and made from nickel

-

A-2 Tool Steel — a very basic and inexpensive steel material often used for tools, blanks, dies, and punches

-

Titanium 6-4 — a grade of titanium often used in aerospace applications

I suspect that Markforged has plenty more new materials in the lab they have not yet announced.

For users of Markforged’s Metal X, this can only be good news, as it means the machine can (or soon will) be used for additional applications. That can make the investment in the machine much more effective.

For new buyers, these materials could make the difference between a purchase and no purchase. In many cases buyers won’t accept a machine “unless it prints in [specific material]”. These new metals could provide the right answer to that question.

Via Markforged

Aerosint and Aconity have proven out their work in multi-metal powder deposition 3D printing.