![[Image: Syos ]](https://fabbaloo.com/wp-content/uploads/2020/05/syos-saxophone-mouthpieces-research-science-design-3dprinting-simulation-acoustic.7d4f8516_img_5eb09bfeb6579.jpg)

The technology of 3D printing has opened an entirely new, nearly limitless medium for instrument makers and artists.

Traditional instruments are being reborn as futuristic masterpieces, and entirely new instruments have also been created. This medium gives the maker total control over how the instrument looks and sounds, and is allowing us to analyze and control sound in an entirely new way. 3D printing is also allowing archaeologists and music historians to recreate instruments that have been lost to history, or instruments whose few surviving examples are too delicate to play. This is giving us a whole new understanding of ancient music and cultures, and allows us to hear music the way it was heard thousands of years ago.

3D Printing and Traditional Instruments

One of the first advancements in 3D printed music has been the remaking of traditional instruments in modern formats. One need only search for “musical instruments” on Thingiverse or Cults3D to see some of the incredibly creative examples that are out there. You will find 3D printed violins, ukuleles, recorders, and many other instruments of varying qualities. 3D printing has lowered the cost and expertise required to get into creating custom musical instruments, and has sparked a whole new interest in the hobby for many amateurs.

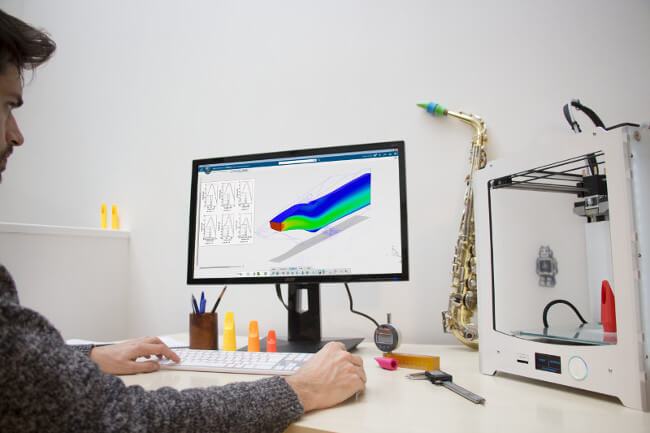

At the same time, advanced instrument makers such as VLNLAB and Olaf Diegel have used the technology to its fullest extent, creating beautiful instruments that rival their traditional counterparts in tone quality and craftsmanship. VLNLAB is a design studio that has created 3D printed violins and violas, and made their plans available to the public for free. Their instruments are of incredible quality and sound, and are simple enough to construct for anyone with a printer to be able to build one. The exactness of 3D printing allows studios like VLNLAB to create different versions, and really play with and dial in the desired sound. This is actually the whole concept of another company called Syos, which creates custom saxophone mouthpieces tailored to the specific sound you desire, using audio engineering.

Olaf Diegel also creates unique 3D printed instruments at ODD Guitars. His guitars play and sound like conventional electric guitars, but have unique artistic shapes that cannot be replicated with traditional manufacturing methods. This creates an instrument that looks like a completely unique piece of art, but plays and sounds like a conventional high-quality guitar.

3D printing has allowed these artists and studios to push instruments beyond their traditional boundaries, creating new twists on old classics and giving them complete control of the desired sound.

New and Never-Before Seen Musical Instruments

Another direction 3D printing has taken music is the creation of completely new, never-before-seen instruments and sounds. No matter what sound you are imagining, it can be made and tailored with 3D printing. While this is a little more conceptual, some artists like MONAD Studio have been experimenting in this field to great effect. They created a unique horn called a hornucopian dronepipe. While it looks and sounds like something from Mad Max, it illustrates this idea of new, never-before-seen 3D printed instruments perfectly. It is loosely based on a didgeridoo, but looks and sounds significantly different, and is a completely new and unique instrument. It has a sound unlike I’ve ever heard, and I highly recommend you take a listen if you are curious:

Another designer named Kent Wardle created an instrument called the “Mixtrument”, it is a series of sections that allows you to mix and match saxophone, woodwind, and horn parts together to create a unique sounding instrument. There have also been a variety of completely electronic MIDI instruments created. While most of these instruments are more experimental than practical, I think it is the beginning of a bright future for 3D printed instruments. In the future there will likely be instruments specifically engineered for certain pieces of music, and vice versa, and it is distinctly possible that someday we will have a completely new class of acoustic and electronic instruments that can only be designed with 3D printing.

3D Printed Ancient Instruments?

The third way that 3D printing is changing music for the better is through archaeology and music history. 3D printing has allowed music historians and archaeologists the ability to recreate instruments whose sights and sounds have been all but lost to history.

One of the more notable recent examples is the work of Billy O’Foghlu with the College of Asia Pacific. Billy discovered a piece in an archaeological collection that was labeled as a spear butt, but he thought it might in fact be an ancient trumpet mouthpiece. Unfortunately, the piece was too delicate for him to try it out. Instead of giving up, he had a company 3D print him an exact replica in bronze. He then affixed it to a replica of an ancient trumpet, and voilà! Not only did it work and sound fantastic, but he created what is believed to be the first ever accurate and complete replica of a horn from that time period and of that style. This is a big deal as it allows us to hear what sort of instruments the bronze age people of Ireland had, and what they actually sounded like! This is something that until recently had only been speculated upon, as very few complete examples of these instruments survived history, and most are far too delicate to be sounded without risking breakage.

Another example is that of the cornett or zink, an instrument that was not only well-known in the 15th through 17th centuries, but was held in the same esteem as the violin in the classical music world at the time. Bach himself wrote many pieces of music for the cornett, and yet the instrument is all but unknown in modern times. This is because it was a difficult instrument to play, and with the advent of modern brass trumpets and trombones many new players would pick up a modern brass instrument rather than a cornett. In addition, the Italian Plague in 1630 killed the majority of cornett makers and instructors. This led to the decline of the cornett and ultimately led us as a society to completely forget the instrument.

Music historians have recently brought the spotlight back to the cornett, and this is where 3D printing makes its appearance. Very few craftsmen alive have the interest, skill, and experience needed to craft one of these fine instruments, but they can be carbon-copied excellently with 3D printing. Cornetti is a company that specifically 3D prints playable, high quality replicas of cornetts and zinks, and has made them available for sale to the public. Thanks to music historians and companies like Cornetti, the cornett has been brought back into view of musicians and composers, and some of Bach’s music can once again be heard on the instrument it was actually written for. 3D printing has allowed us to experience early European music the same way that early Europeans heard it, and has brought back one of history’s finest instruments from the brink of being lost forever.

The Future of Music

Music is a universal language, and 3D printing has forever changed the way we make and interpret it. The cultural value of this is immeasurable, and thanks to 3D printing we can once again hear ancient instruments lost to time. It also has opened a whole new realm of possibility for the musical arts, one that as yet has only been tapped by the courageous few. It will bring traditional instruments into the future, and also allow the creation of music in ways we have never seen before. 3D printing is changing music forever, and the results are positive and enriching for all who encounter them.