![Project MAESTRO’s goals [Source: MAESTRO]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09fb01554b.jpg)

The EU is sponsoring an interesting 3D print technology project called “MAESTRO”.

The project began in 2016 and is set to complete in 2019, specifically September 30th, so the results are only a few months away. It brings together industry, government and academia to attempt development of a solution for long-term 3D printing technology growth.

Specifically they wish to address the issue that current metal 3D printing technologies are limited in scope to small batch runs at most, and usually for prototyping. They explain:

“The AM technology has matured to reach a level where it can be considered as a viable alternative for producing net shape metal components for relatively small markets, predominantly for prototyping and small batch manufacture.

This means only for low-scale applications where one material is used, the accuracy is not too high and surface integrity is achieved in one single AM processing step.

Now it is necessary to improve productivity, cost and speed to bring this technology to a larger scale, towards mass market applications.”

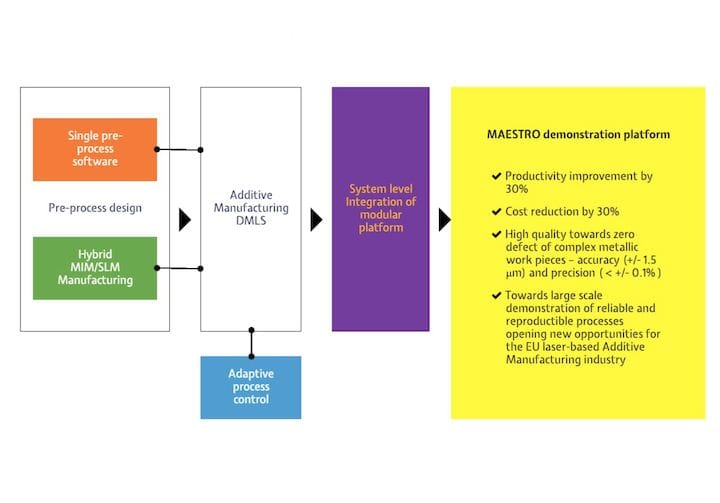

Their concept is to move through the flowchart as shown at top towards the release of a development platform. According to their documentation, their goals are to produce a platform that:

-

Increases productivity by 30%

-

Reduces costs by 30% (which may come along automatically with the productivity goal)

-

Achieve print accuracy of within 1.5 microns and precision within 0.1%

-

Achieve large scale reproducible processes

To work towards these goals MAESTRO has gathered together an interesting collection of industry participants, including:

-

Altair: Design simulation software provider

-

EOS: Long-term metal 3D printer manufacturer

-

IPC: Plastics expertise

-

Gemmate: Technology scale-up

-

Alstom: Railway applications

-

CRF: Environmental sustainability

-

University of Birmingham: Academic research

-

OBE: High-precision metal components

-

CEA: Energy technologies

-

III-V Lab: Semiconductors

This group has been provided with nearly €4M (US$4.6M) to achieve their goals.

What have they achieved so far? By reading through their earlier news releases, it seems they’ve attempted to work towards the goals by implementing a variety of smaller demonstration projects. They have, for example, produced a machine that is a hybrid between a casting process and DMLS. They’ve also produced weight-optimized sample parts that could be eventually produced in metal materials.

One of their key outputs will be a metal 3D printer that uses the DMLS process, but with MIM (common Metal Injection Molding) powder. They explain:

“In this project, OBE and CEA are in charge of the development and characterization of an hybrid DMLS/MIM demonstrator, by measuring the mechanical properties of the DMLS/MIM interface. OBE produced four batches of a MIM feedstock based on different standard 316L powders, three-powder gas atomized and one water atomize.”

If they can achieve this alone, the project could be quite worthwhile; standard metal 3D printers of today frequently require highly specialized fine metal powders that end up being quite expensive. Some materials can cost upwards of US$500 per kg! Meanwhile, every city has distribution centers providing hundreds, if not thousands, of types of MIM powders at commodity-level pricing.

![Example of hybrid manufacturing where MIM parts are joined to DLMS parts [Source: MAESTRO]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09fb081d81.jpg)

Here we see the results of one of their experiments, showing the different microstructures achieved from joining a standard MIM component with a DMLS-produced layer. They say this means such parts could be successfully manufactured.

I’m quite interested to see the results of this project, as the project releases thus far seem to be only pieces of a larger jigsaw puzzle.

Via MAESTRO

A research thesis details the incredibly complex world of volumetric 3D printing. We review the highlights.