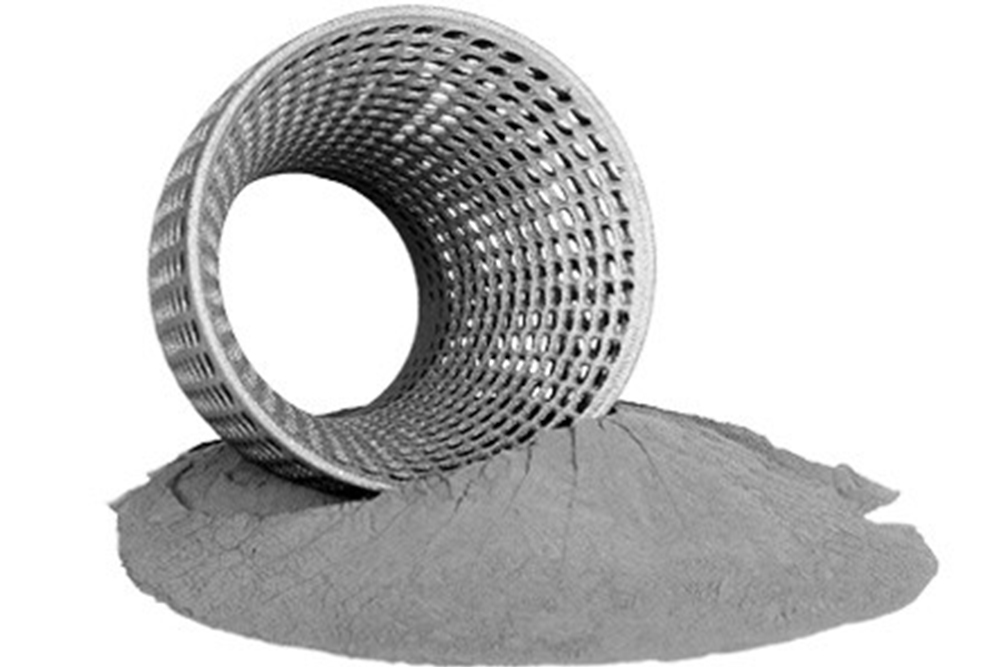

![[Image via ANSYS]](https://fabbaloo.com/wp-content/uploads/2020/05/simulation-unlocks-additive-manufacturing-potential-metal-part-powder_img_5eb09de933050.jpg)

An important acquisition in simulation and materials intelligence has been flying under the radar.

Last week, ANSYS announced its definitive agreement to acquire UK-based Granta Design. Pittsburgh-based ANSYS, which develops innovative engineering simulation software, is bringing Granta’s well-regarded materials information technology into its portfolio. The move was announced on Tuesday and its applicability for additive manufacturing has so far been a quiet achievement.

The two companies announced a partnership in October, focusing on the importance of “accurate, reliable and traceable materials information,” which they noted immediately is “crucial for additive manufacturing.”

The partnership release explained:

“The combination of ANSYS’ powerful simulation for metal powder bed AM with Granta’s existing GRANTA MI: Materials Gateway for ANSYS Workbench offers an integrated set of workflows for AM data capture, simulation and optimization. That enables users to directly access and use validated materials data stored in their GRANTA MI corporate materials database, while working in ANSYS Workbench. Users can quickly apply accurate, traceable input data, saving time and increasing confidence in simulation results. The companies are also working to connect ANSYS Additive Print to GRANTA MI.”

ANSYS’ Director of Additive Manufacturing, Brent Stucker, was enthusiastic about that partnership. He said at the time that work with Granta would help the team “to assure that ANSYS AM solutions will not only become more efficient, but more accurate and reliable over the years to come.” Bringing together ANSYS’ simulation with Granta’s physical prowess can ensure more first-time-right additive manufacturing, as material properties are indeed a critical consideration for a 3D print job.

I spoke with Stucker today, and he noted that the Granta acquisition is a major move for ANSYS. Additive manufacturing applications are just part of the story of what the teams will have to offer — but it’s an important aspect.

Materials information is critical for good simulation, Stucker underscored. Materials are increasingly being formulated specifically for additive manufacturing, which is an important undertaking. Understanding every piece of information ensures that simulation can do its job properly; inputting the exact parameters of a build allow for the software to correctly work with the specifics of each job.

The acquisition will close this quarter, and over the course of 2019 ANSYS will integrate Granta’s material database into their own additive manufacturing portfolio. Customers in need of full traceability and understanding are increasingly on the lookout for better solutions. Stucker noted that aerospace users in particular have been asking for this ability.

“One key thing is that Granta was founded by two professors from Cambridge University who are world leaders in material science. It as a company is a world leader in materials information, getting materials information into simulation and design and anywhere where you need to understand materials,” Stucker told me.

“Materials in additive is very complex — when you change the parameters you come up with different properties. Bringing that history of best-in-class materials intelligence into the ANSYS portfolio and applying it directly to additive manufacturing will give designers access to all kinds of materials information they otherwise wouldn’t have access to.”

Simulation software is of great importance in engineering — as well as in additive manufacturing. As with materials, though, offerings specifically applicable to the unique demands of and parameters for 3D printing are often lacking. ANSYS is looking to overcome this existing obstacle with more targeted solutions in a market that has some, but not enough, information available.

Stucker, who was the CEO of 3DSIM, acquired by ANSYS during formnext 2017, has great experience in the additive environment. While the Granata acquisition will have impact throughout ANSYS’ portfolio, Stucker pointed out the value specific to 3D printing in noting that these applications will be leading the way for the integration.

Bringing together well-regarded simulation capabilities with leading information on materials is a strong move as ANSYS’ portfolio fortifies with additional expertise.

Via ANSYS