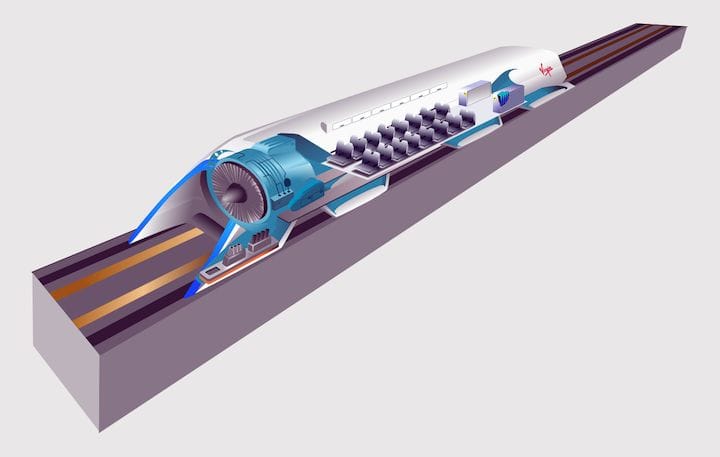

![Hyperloop concept [Source: Wikipedia]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09ea0036d5.jpg)

This week’s question is a bit unusual.

Reader Carl asks:

“Have you ever thought about printing a tunnel liner with PVC or some other polymer making it smooth and waterproof with metal reinforcements if necessary? Maybe a hyperloop tube?

Maybe talk to Elon Musk, he really enjoys new ideas.”

No, we haven’t thought about this possibility, and there are reasons not to.

A hyperloop, if you’re not familiar, is a new transportation concept promoted by Elon Musk. The idea is to shoot cargo or passenger capsules through tunnels or tubes at extremely high velocity over long distances. Projected speeds would be vastly more rapid than even the fastest bullet trains, even exceeding the speed of sound!

That seems preposterous, as all kinds of severe mechanical and aerodynamic effects occur at such velocities. However, the secret to the hyperloop is to evacuate the tunnels and tubes so that there is near-zero air friction. Thus the capsules can travel as fast as they can accelerate without major issues.

Back to the question. Could liners for hyperloops be 3D printed?

While I’m not aware of any devices doing so, it is likely possible something of the sort could be built. I would imagine a largish 3D printer that extrudes a cylindrical shape in vertical orientation. Printed sections could then be installed somehow in the hyperloop tubes.

But that’s a theory, and I see many issues in doing so.

First, the hyperloop operates in a vacuum. There is by definition no molecular contact between the traveling capsules and the tube itself. Thus you do not need to make a “smooth surface” for the capsule to travel upon. In fact, the tube inner surface could be quite rough and it wouldn’t make any difference in the aerodynamics – because there aren’t any!

Secondly, printing liners in this way could be extremely expensive. We all know that 3D printing today is best used for unique prototyping or at most low-volume production. In the case of a large tunnel like a hyperloop that connects cities, or even countries, staggering numbers of liner sections would be required.

For example, a hyperloop between San Francisco and Los Angeles, a distance of 560km, would require, literally, 560,000 1-meter tunnel liner sections. If the time to print one of these sections was, say, six hours as a fairly rapid pace for today’s bulk 3D printers, we’d require 3,360,000 hours to complete all the prints, or just under 400 years. By doubling the number of printers on the case you could reduce this to “only” 200 years. You get the idea.

So this is not really feasible, even without considering the financials.

For tunnel liners there are likely far better technologies that could produce the effect faster and at a far lower costs. I imagine some kind of spray-robot that could traverse the tunnel could apply a surface coating fairly quickly, for example.

This is a case of choosing the right tool for the job. 3D printing is merely one tool in the toolbox, and like every other tool, it should be used when it makes sense.

And we’ll pass on making suggestions to Musk; he’s already got more ideas than we ever had.

Image Credit: Camilo Sanchez / Wikipedia