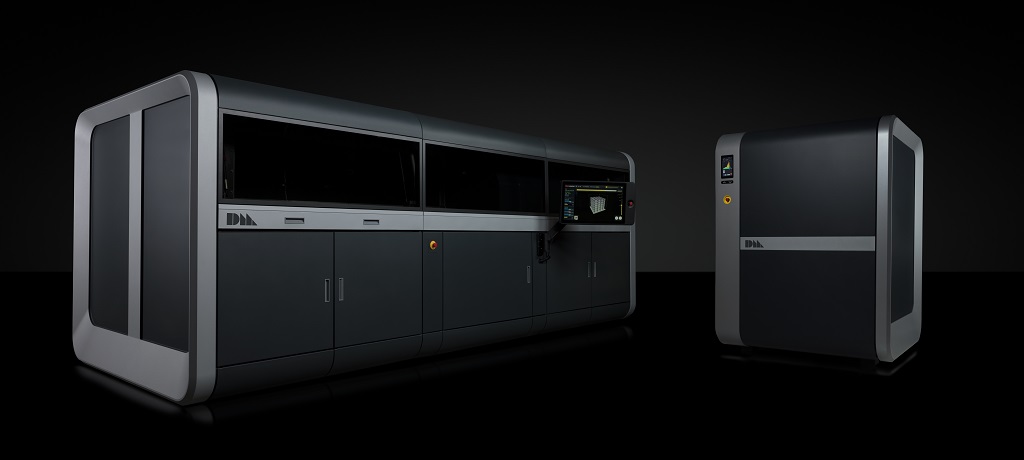

![The Production System [Image: Desktop Metal]](https://fabbaloo.com/wp-content/uploads/2020/05/ProductionSystem_img_5eb09e2d53307.jpg)

A $160 million investment brings Desktop Metal’s combined funding to $438 million.

Investment news is absolutely picking up in 3D printing. Funding rounds for new technologies and young companies furthering post-processing are regularly in the headlines — and these are big news indeed, as the cash flow demonstrates investors’ confidence and enables new advances. These announcements are significant to the companies as hundreds of thousands, millions, or even tens of millions of dollars fund the next steps forward for business plans and process evolution. But today we’re talking hundreds of millions.

3D printing remains a nascent technology and very young industry. Growth rates are high, but concrete numbers remain, as yet, low in terms of revenues and installations. Adoption is growing, but a steep learning curve and some hesitation among new adopters in manufacturing are among the common barriers to entry for further growth. What this industry really needs is a major vote of confidence.

Enter Desktop Metal.

The Boston-based unicorn has been making waves in metal 3D printing since the first whispers of its tech promises emerged a few years ago. With today’s funding announcement, the latest in a seemingly ongoing series of such announcements — and not its first nine-digit funding — the company says it is now “the highest funded private 3D printing endeavor in history.”

The $160 million Series E funding round was led by Koch Disruptive Technologies (KDT) and also included GV (formerly Google Ventures), Panasonic, and Techtronic Industries, as well as previous venture capital investors including Lux Capital, New Enterprise Associates (NEA) and Kleiner Perkins.

“Desktop Metal’s 3D printing solutions can redefine prototyping and mass production of metal products, which has profound disruptive implications for manufacturers like Koch Industries. We are very bullish about the prospects of Desktop Metal, not just as an investor, but also as a customer and partner,” said KDT President Chase Koch.

Systems from Desktop Metal are designed to make metal 3D printing more accessible (see the Studio System) as well as more productive (see the Production System).

I caught up briefly with Desktop Metal CEO Ric Fulop. Indicative of the nonstop pace he and his company are keeping, he called from Switzerland where he’s attending the World Economic Forum this year. At midnight after a long Davos day, the enthusiasm still came through.

“I’ve been going nonstop since the morning,” Fulop told me of his Davos experience. “It’s interesting. I’m meeting lots of customers, people you thought would never need a metal 3D printer. But metal parts are used in all sorts of stuff, if you can change the design of products it really opens the possibilities.”

The theme at this year’s Davos is Globalization 4.0 — and that pervades for Desktop Metal as well. Fulop touched on the growing channels for the company’s equipment; the Studio System, for instance, is available through more than 85 sales partners in 48 countries. That global network is necessary as these systems are now shipping in volume. From Ford to Stanley Black & Decker, from Goodyear to 3M, early customers include a who’s who in a variety of industries — as well as in defense (the US Department of Defense and Department of Homeland Security) and education (e.g., MIT, Diman Regional Vocational Technical High School).

This investment round is exciting all around to the growing Desktop Metal team. Investments, as KDT’s Koch noted in today’s announcement, don’t mean just money, but use and partnership. Fulop is enthusiastic about “lots of potential opportunities to work together with Koch Industries.” The parent of KDT has a wide reach, and Fulop says he and his team are “very excited for this opportunity.”

We’ll be hearing about more customers for Desktop Metal’s systems throughout 2019, which is already shaping up to be a(nother) big year for the company. The Production Systems will begin shipping next month. We can also anticipate “more fun stuff throughout the year,” Fulop teased, with AMUG and RAPID promised to have plenty for Desktop Metal to “show off.”

The timing for Desktop Metal is interesting, as the 3D printing industry continues to swing industrial. Additive manufacturing is becoming more of a mainstay in manufacturing, and big names — and big numbers — are showing the increasing trust in young technologies that are proving themselves.

“We are at a critical juncture in the advancement of metal 3D printing and additive manufacturing,” Fulop said in today’s announcement. “We are excited about Koch being an investor, customer and capability provider in this round. This new funding will fuel the continued development of our metal 3D printing technology and rich product roadmap, the scaling of operations to meet a growing demand of orders, and the financing of major new research and development initiatives. Combined, this will set us on a trajectory to become a global leader in metal 3D printing, a key pillar of Industry 4.0.”

From the sound of it — and I wish I could say more already — there’s plenty in store for Desktop Metal as 2019 kicks off. The company’s roadmap is detailed and long, and this latest investment is helping to light that path forward.

Via Desktop Metal

Tech Soft 3D, a producer of powerful toolkits for CAD/CAM applications, received significant funding.