![The new Pro series extrusion system from Dyze Design [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a1798155e.jpg)

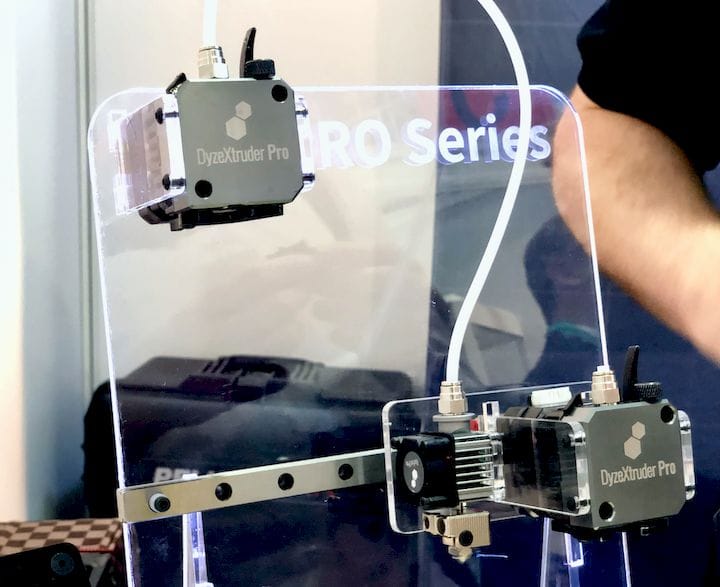

Dyze Design showed us their new products.

The Montreal-based company is unusual in the 3D printing space as they don’t manufacture 3D printers per se, but instead focus on high-quality components that can be used to build 3D printers. Or upgrade them, for that matter.

The specific components at issue here are hot ends, extruders and nozzles, which the company has been producing for several years. We’ve previously noted some of their products, such as a a powerful extruder, sapphire nozzle, and a filament-out sensor.

Now the company has some rather interesting new products to add to their line.

The new Pro series hot ends and extruders are priced at US$130 and US$200, respectively, or US$315 for both in kit form. The Pro series sports thumbscrews for instant release, allowing very quick changes. Nozzles can be swapped very quickly, and it is capable of running a faster flow than previous extruders due to a new internal guide system.

The internal coating is made from stainless steel and ceramic, making it a bit more slippery.

![The Typhoon extrusion system from Dyze Design [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a179df628.jpg)

Another new product is the Typhoon, shown here. The advanced extrusion system is 6X faster and is able to extrude 200 cubic millimeters of material per second. It’s water cooled and includes a pressure and jamming sensor. It’s capable of adjusting the flow each second. Expected price is US$2000.

![The powerful Pulsar pellet extruder from Dyze Design [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a17a2f6d1.jpg)

Dyze Design’s ultimate extruder must be their new Pulsar system, designed to extrude thermoplastic pellets with a unique custom-designed screw-style system. This huge device can extrude 2.5kg of material per hour!

![Multiple heating zones on the Pulsar extrusion system from Dyze Design [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a17a748a1.jpg)

An internal sensor can detect an out-of-pellets situation, as the system includes a small PCB making this perhaps the smartest extruder around. And to get one, you’ll have to pay them around US$5,000.

All of the extrusion systems from Dyze Design are able to hit a very high 500C, enabling them to 3D print in almost any common thermoplastic engineering material. They also provide very hard tungsten carbide nozzles that are highly resistant to wear, yet provide adequate thermal transmission.

![Multiple sizes of tungsten carbide 3D printer nozzles from Dyze Design [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a17aeff75.jpg)

Two of these products are clearly targeted at industrial uses, rather than desktop equipment; no hobbyist is going to have a high-speed pellet extruder. Thus Dyze Design is shifting their market to a more profitable space.

It could be a very strategic move because of the greatly increasing interest in high-speed 3D printing for manufacturing. This demand will cause the development of many new industrial 3D printers, each of which could potentially use the Typhoon or Pulsar extrusion systems.

Good times for Dyze Design!

Via Dyze Design

An Austrian company has developed an incredibly sophisticated end-to-end automation system for metal 3D print post processing.