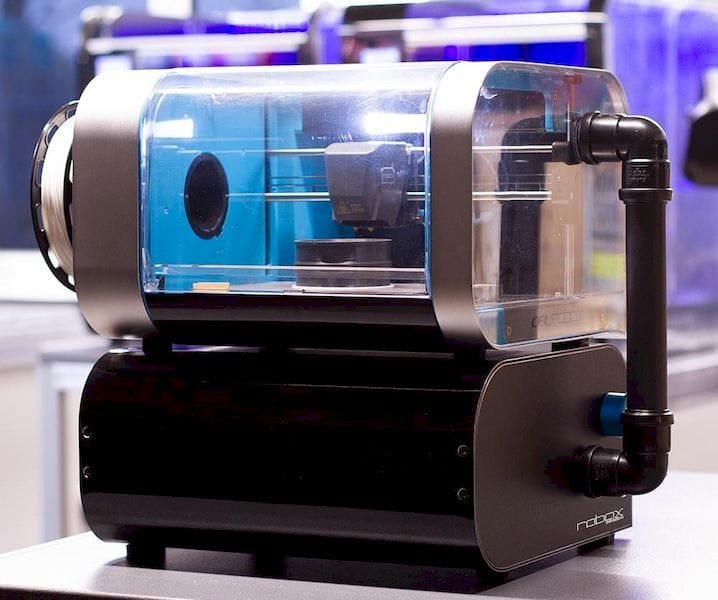

![Reduce emissions from your 3D printer with the RBX-XT1 [Source: CEL-ROBOX]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a18b63504.jpg)

After publishing our rant about the increasingly important lack of attention paid to safety in 3D printing, we received an interesting tip.

My rant, provocatively entitled “Does ANYONE Care About 3D Printer Emissions?” was an attempt to again raise attention to the ongoing of 3D printer emissions. Yes, there are some who do care about 3D printer emissions, but the majority do not appear to do so, given the state of products being marketed.

A slim percentage of 3D printers on the market include even air filtration systems, and those don’t really get at the invisible problem of nanoparticles because the HEPA filters typically used have far too large meshes to catch the extremely tiny nanoparticles being emitted. And VOCs (volatile organic compounds) are not caught at all.

In spite of my despair that essentially no 3D printers known attempt to properly secure all the nasty stuff emitted from machines, some companies at least make an attempt at safety.

Some manufacturers’ machines sport full enclosures that will physically limit nanoparticle ranges; others might include a combination HEPA filter / activated carbon filter to capture larger particles and eliminate any generated odors. That’s good, but incomplete.

However, the vast majority of 3D printers on the market have none of this. An inspection of 3D printers listed on AliExpress, a popular sales online sales outlet for Asian goods, shows almost all machines being fully open to the air and obviously no possibility of filtration.

A few machines have enclosures, but they’re typically for performance reasons – enclosures capture heat and raise the ambient air temperature during printing, making it less likely you’ll have a print failure due to warping. However, most enclosed systems also do not have filtration systems.

But could you add a filter to them?

There are quite a few laboratory filtration units that are available on the market. But in my looking they seem to be rather expensive, sometimes overkill and appear challenging to physically install.

If only someone would make a filtration attachment specifically for 3D printers.

Wait a moment – someone did! Reader “suds” points us to an accessory product from UK-based CEL-ROBOX, who manufacture high-quality desktop 3D printers that we’ve covered several times in the past. The company, which should be more well-known that it is, has developed several very interesting technical features not found on other equipment, such as their innovative “needle valve” that prevents nozzle leakage.

Now we find they also make the RBX-XT1, a “Robox Extractor with HEPA and Activated Charcoal filtration”. Here they explain what it does:

“Robox Extractor collects air from the build area and filters it through two stages of a replaceable filter containing Activated Charcoal and HEPA sections.”

The idea here is that you can attach this machine to your 3D printer and it will pull air from the build chamber – which is likely infested with emissions – and push it through the filtration. While this machine does not catch the nanoparticles or VOCs, it is a big step forward in safety.

It’s obviously designed with their own equipment in mind, specifically their non-PRO line that does not include an onboard filtration system. However, it’s highly likely this unit is adaptable for other 3D printers equipped with an enclosed build chamber. Two holes, one to allow fresh air in, and another for the RBX-XT1 to pull air out, would be required.

The pricing of the RBX-XT1 is reasonable, when compared with most high priced laboratory filtration systems, at £349.90 (US$446).

If you have an enclosed 3D printer without filtration system, this might be a good choice as a means to increase the safety levels on your equipment.

Via CEL-ROBOX (Hat tip to “suds”)

We were able to view video footage of the 3D printing hair-caught incident from last week and have determined exactly how it occurred, and how to prevent it from happening again.