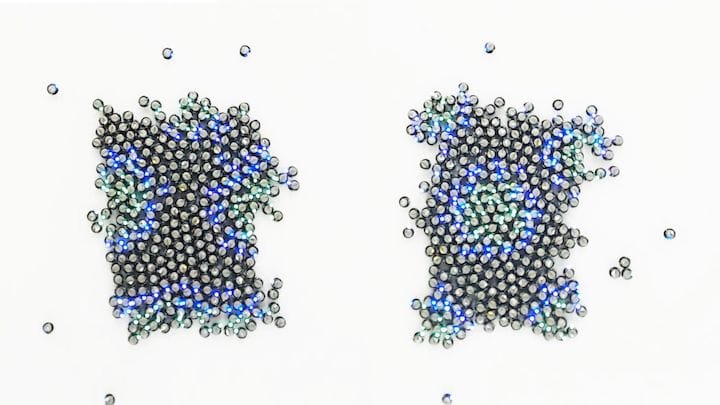

![Self organizing robots could hint at an interesting future for 3D printing [Source: Technology Review]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09ffb7361c.jpg)

New research from MIT hints at future possible approaches to 3D printing.

The research investigated the possibility of developing self-organizing swarms of devices. Swarms have long been able to assume forms, but only by having them pre-programmed to develop specific shapes. The new research determined it was indeed possible for independent robotic swarms to self-organize into arbitrary shapes derived from a basic set of rules.

They explain the objective in their paper’s abstract:

“Morphogenesis allows millions of cells to self-organize into intricate structures with a wide variety of functional shapes during embryonic development. This process emerges from local interactions of cells under the control of gene circuits that are identical in every cell, robust to intrinsic noise, and adaptable to changing environments.

Constructing human technology with these properties presents an important opportunity in swarm robotic applications ranging from construction to exploration. Morphogenesis in nature may use two different approaches: hierarchical, top-down control or spontaneously self-organizing dynamics such as reaction-diffusion Turing patterns.

Here, we provide a demonstration of purely self-organizing behaviors to create emergent morphologies in large swarms of real robots. The robots achieve this collective organization without any self-localization and instead rely entirely on local interactions with neighbors. Results show swarms of 300 robots that self-construct organic and adaptable shapes that are robust to damage. This is a step toward the emergence of functional shape formation in robot swarms following principles of self-organized morphogenetic engineering.”

Before you get suspicious of this work by thinking this may be the first step towards robot armageddon, consider there may be alternative futures that are much brighter. One could be 3D printing.

In almost every 3D printing device on the planet today there is a single actuator that is extruding, depositing, fusing or binding a material. Yes, there is some limited parallelism, such as in the EOS powder bed laser systems that now can include up to four independently operating lasers. Machines with independent extruders can sometimes be seen with two toolheads. And binder jets do use inkjet mechanisms with zillions of fluid droppers.

But these examples of 3D printing parallelism are still quite limited, and as a result we often have very slow print speeds. Print speeds are so slow we don’t even contemplate producing larger structures with such equipment.

But what if things were different?

What if you could “release” dozens or even hundreds of independently operating “toolheads” that could in parallel participate in the joint construction of a 3D object?

I think you might see print speeds rise very dramatically. An object that might take seven hours to print with conventional 3D printing approaches might take only a minute if, say, 1000 toolheads could be simultaneously used.

Of course, there are countless issues to resolve. How could that many toolheads work without bumping into each other? Would there be space for them to work together? How would you supply them with input material? How could you control their movements to ensure the right object gets built?

Oh wait, that last one might be solved, or at least taken steps towards it with this research.

If a swarm of robots could self organize into a useful pattern, then what might happen if they were equipped with actual deposition toolheads? You might be able to create a massively parallel 3D printing process.

This approach would likely not be useful for smaller objects, but instead be more useful when 3D printing larger – or perhaps very large – objects. Perhaps this could be a way to, say, organize a fleet of mobile construction 3D printers to build a permanent structure?

While the authors of the paper don’t specifically mention 3D printing as a possible beneficiary, I think there might be something very powerful here.

Via ScienceMag and Technology Review

A research thesis details the incredibly complex world of volumetric 3D printing. We review the highlights.