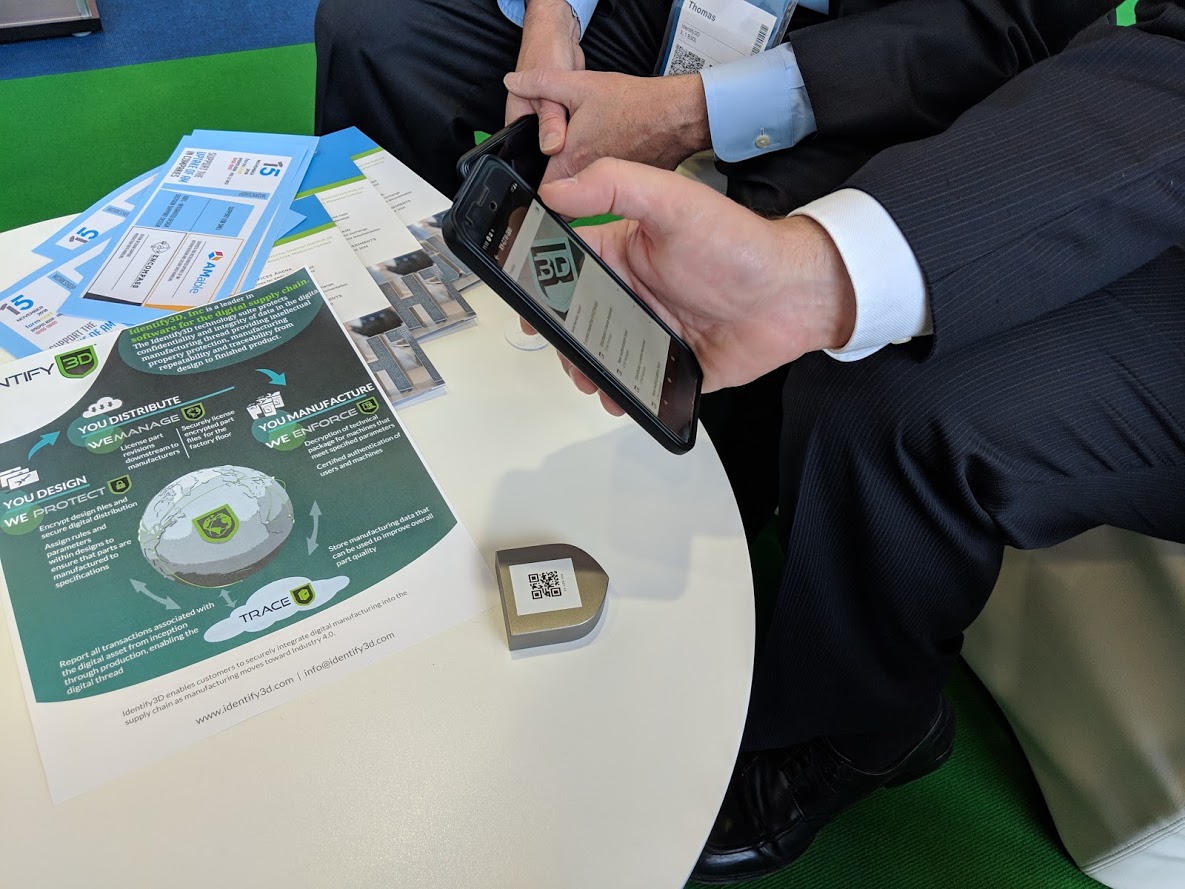

![The Identify3D team at formnext 2018 [Image: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/IMG_20181113_110545_img_5eb0a110af09c.jpg)

Digital supply chains and digital manufacturing solutions are on the rise — and real success will depend on intellectual property management.

Identify3D was founded to protect intellectual property (IP) as digital manufacturing ‘explodes in its growth and breadth of applications.’ Maintaining the integrity of proprietary information and files is critical as assets are distributed around the world.

The company explains its mission:

“Identify3D was born in beautiful San Francisco in 2014. We are excited to see the Digital Manufacturing Industry exploding in its growth and breadth of applications. With this growth we saw the need to better protect companies’ unique designs and Digital Manufacturing assets. From this need Identify3D was born. We help protect the intellectual property of the original design from unauthorized distribution, transformation, replication, and production. We also help the design retain its original quality by coupling production standards and manufacturing rules (machine, consumable, key set-up parameters) to the design that must be authorized and authenticated before production can occur. Lastly, we give companies the ability to have Digital Manufacturing give them actionable feedback through our in-depth analytics.”

Co-Founder and CSO Stephan Thomas shared more details about the latest developments when we sat down to catch up at the recent formnext.

Focus recently has been on the need to integrate with machine manufacturers, Thomas noted, as direct relationships with 3D printing companies ensures end-to-end protections can be built in through the entire workflow. By the end of next year, Identify3D should be integrated into 80-90% of machine solutions, he said. Working presently with major suppliers like EOS, Renishaw, and SLM Solutions, with at least three others in the pipeline that are not yet public, Identify3D is well on its way to its goal.

The value proposition as Thomas explains it is built on three pillars:

-

Protect data

-

Only license the data for so many builds, specified to work with a given machine and a given material

-

Traceability

“We need to be sure of authenticity — overall, it’s a story of integrity of supply chain,” he said.

For Identify3D, the important thing is to track data, and so the team are working with several methods to find the best fit for each user. QR codes, for example, can be scanned into Identify3D’s Trace software and display the design file and data about where and when the part was made.

“It’s all about authenticity and traceability. The backbone is there and we are building up,” Thomas continued.

Another big buzz in tech these days is blockchain, and Identify3D has developed a proof of concept to validate this approach as well. They are exploring opportunities in the use of blockchain for suppliers, remaining in the proof-of-concept phase for now.

“We’re not a blockchain company per se, but we’re working with it,” Identify3D Co-Founder and CEO Joe Inkenbrandt added.

Blockchain and QR codes are means to the greater end for Identify3D: the big picture is traceability.

“It’s tracking in different forms — whatever the client is using, we want to work with. We want to make it easy to do: scan the part and get information from the original file,” Thomas said.

Identify3D has filed patents on its technologies as IP becomes more a part of the conversation in all aspects of digital manufacturing.

“We’re talking more about production in 3D printing now, and these issues are coming up more. They hadn’t been at the forefront, but we’re talking about them now as we’re going into production,” Thomas continued.

He noted two musts for production:

-

Have to make parts the same way

-

Need to trust that the right thing is being done with the file

Getting ahead of any potential issues in IP will be key to the success in these early days of digitization. In speaking with several service bureaus, Identify3D identified existing need for security in file handling.

“Many are just passing a USB around with these design files; we want to talk about this before there’s an incident,” Thomas said.

Identify3D also teamed up recently with InfraTrac, which “has introduced chemical fingerprints, extending traceability to field authentication” and “aligns with the Identify3D Digital Supply Chain Platform and can incorporate blockchain where needed.” Sharon Flank, the CEO of InfraTrac, appeared with the Identify3D team for conversations on solutions during formnext.

![InfraTrac CEO Sharon Flank with team Identify3D [Image: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/IMG_20181113_110553_img_5eb0a1126bf53.jpg)

Working with manufacturers to integrate solutions directly, as well as with users to identify the best-fit solutions and means of tracking to work with their systems, Identify3D is getting hands-on in the industry they seek to serve. The company’s expanding list of partners is testament to the need for solutions and security in digital manufacturing.

Via Identify3D