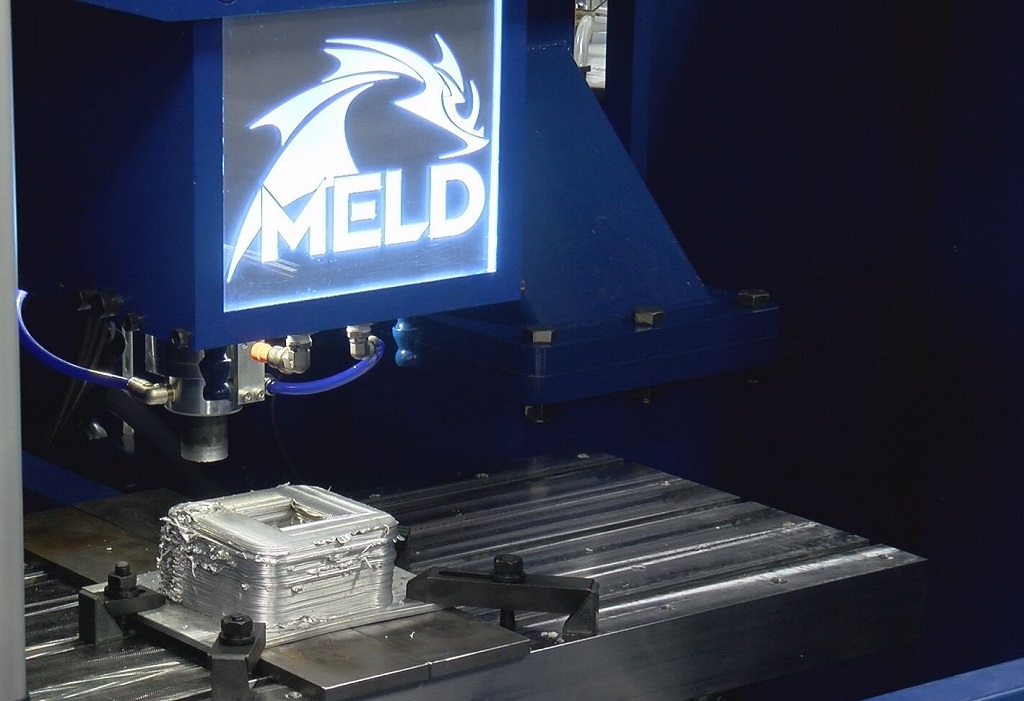

![[Image via WDBJ7 ]](https://fabbaloo.com/wp-content/uploads/2020/05/MELD_img_5eb0a210e552f.jpg)

MELD Manufacturing launched earlier this year; we caught up with the CEO for a look into what sets this process apart.

Nanci Hardwick, CEO of Aeroprobe Corporation and MELD Manufacturing Corporation, shares insights into the unique MELD process as well as a bit about what we can expect going forward from this Virginia-based company.

Can you share a look at the background and recent launch of MELD Manufacturing?

“The MELD technology was created by a research and development division of Aeroprobe Corporation over the course of more than a decade. In April 2018, MELD Manufacturing Corporation was launched to usher in the next era for the process. We currently provide machines sales, contract manufacturing, and consulting services.”

What sets the MELD process apart from other metal additive manufacturing technologies?

“MELD is a solid-state process, meaning the material does not reach the melting point. By not melting, we avoid the many issues that plague melt-based technologies, such as hot cracking. Furthermore, remaining below the melting point means that materials that aren’t compatible with other processes can be MELDed, including unweldable metals. MELD is also uniquely open-atmosphere. The special chambers and vacuums required to operate other processes, especially laser-based technologies, aren’t needed for MELD. This feature enables MELD machines to go places other technologies can’t. The equipment is also fully-scalable, allowing MELD to make much larger parts than other processes.”

What applications would be a good fit for solutions using MELD technology?

“One of the great things about MELD is its versatility. Our customers come from a wide range of industries, from aerospace and automotive to communications and defense. In addition to additive manufacturing, MELD can repair, coat, and join materials.”

Can you tell us about the partnerships announced recently regarding battlefield scrap and next-generation combat vehicles?

“MELD, in collaboration with the University of Alabama, has been awarded funding from the Strategic Environmental Research and Development Program (SERDP) to research using our process to recycle battlefield scrap in combat theater. We were also selected by the US Army to take part in their XTechSearch due to MELD’s potential to create lighter-weight, high-strength materials for combat vehicles.”

What makes metal 3D printing and specifically MELD interesting to the defense industry?

“MELD is unique in that it gives users extreme material flexibility not just in the types of metal that can be used but also in what form that metal is in, from solid bars to powders and beyond. This feature is appealing to members of the defense community due to the large amount of scrap material that is generated on the battlefield. Currently, this material is burdensome and considered waste. MELD offers the potential to take that scrap and manufacture or repair components onsite, saving time and money. Since MELD machines can be scaled to different sizes and the technology can be equipped on a robotic arm, MELD is able to go places that other technologies can’t. In addition to making battlefield scrap a useful resource, members of the defense industry are interested in MELD’s ability to make lightweight components for military vehicles. Reducing the weight of these vehicles cuts fuel costs and also allows them to travel further between refueling, making them safer and more efficient than current vehicles.

MELD is appealing to the defense community as a whole because it is the safest, most portable, user-friendliest process for not only AM, but also for repair of small to large metal assets at a shipyard, forward operating base, or even in space.”

How does the open-atmosphere operation enable functionality in various manufacturing environments?

“Many competing processes, especially those involving lasers, require special vacuums or chambers for operation. This increases not only the amount of space required for these machines, but also the initial and day-to-day costs of running them. In contrast, a MELD machine can be placed virtually anywhere there is enough space for its footprint with no need for these chambers or vacuums. This also means that MELD machinery can increase in size to make large parts far beyond what other technologies are capable of producing. MELD can even be equipped onto a robotic arm for onsite repairs. To put it simply, MELD can go places competing technologies can’t. We’re putting AM technology in places it’s never been before.”

How has market reception been since launch?

“The market reception to MELD has been overwhelming. We’ve seen interest from industries all over the world.”

How did the Innovation Award win at RAPID + TCT this spring speak to the viability of the MELD process?

“RAPID + TCT was our first official conference as MELD Manufacturing Corporation, so to take home the prize our first time out was a major win. It just shows how legitimately different this technology is and how big of an impact it’s going to have across industries. To be recognized by our established peers in the AM community as an innovation demonstrates our viability.”

What can you tell us about plans for the rest of this year? Next year? The next five years?

“The rest of 2018 will be devoted to continuing to get the word out about MELD. We’re offering a brand new technology that breaks a lot of established rules in AM, so it takes time to help customers understand exactly what our process can do. Next year, we will continue to offer machine sales and services and have ongoing marketing efforts to establish our brand as the future of AM. The 2019 conference schedule will be busy and we plan to have a MELD machine onsite at next year’s RAPID + TCT conference. Within the next five years, we hope to see MELD dominate the industry with machines in manufacturing and research facilities across the globe.”

What else should we know about MELD Manufacturing?

“MELD is truly unlike any other process and gives users an unprecedented amount of freedom. We’re giving our customers the power to choose what types of material they want to use and offering a machine that is a revolution in the AM industry, but is also capable of much more. Our goal is to see the world making new things in innovative ways with unique materials. To help the execute that goal, we are working with customers to create purpose-built equipment.”