![3D printer emission sources [Source: Taylor Francis Online]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a23bd25fe.jpg)

After reading more scary papers researching 3D printer emissions, I am baffled by the industry’s lack of response.

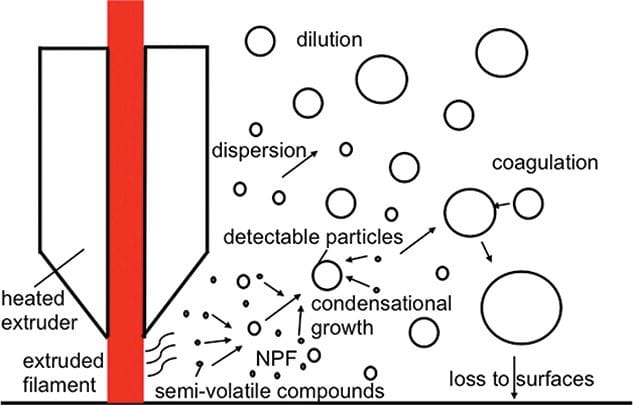

The issue is that in filament-based 3D printers the material begins to emit microscopic particles and volatile organic compounds (VOCs) when heated. These tiny materials become airborne, where they can potentially be breathed in by passersby, or land on food or drink, to be consumed by unsuspecting individuals.

The research papers investigated the phenomenon in some detail, but frankly their results are simply confirming work previously done by others in the past. This is a well known issue.

Their findings suggest that:

-

Some materials emit more than others, with plain PLA being the least emissive and ABS the worst

-

The higher the hot end temperature, the more emissions take place

-

Additives in materials can dramatically change the amount and type of emissions

ABS is so bad that you can usually smell it when printing. However, just because another filament does NOT smell does not mean it is not emitting particles and VOCs, which can be undetectable without specialized equipment. The particles and VOCs can become lodged in your lungs forever. Their presence could potentially be bad, but no one has proven any specific links to medical issues, as it would take some time.

The correct approach is to externally vent your 3D printer to simply move all VOCs and particles outside. However, I suspect that a huge percentage of 3D printers are not configured in this way.

Please review these papers and become informed. I’m not going to go into more detail about their findings here, as we’ve written countless times about it in the past.

Instead I am going to rant about the almost complete lack of attention to the issue by 3D printer manufacturers.

Almost without exception 3D printers are unable to prevent these emissions. Yes, some manufacturers produce machines that have completely enclosed build chambers, which, according to the research papers, does limit the emissions somewhat. But there are inevitably fans that blow air from inside to the outside, where they enter the atmosphere.

But there’s filters, you say.

Yes. Some manufacturers employ HEPA and/or activated carbon filters in an attempt to reduce emissions. While that may sound like a good strategy to eliminate problems, they really only eliminate the smell. The microscopic nanoparticles and VOCs pass through the coarse HEPA filters easily.

It’s true that filtering such small particles and chemicals is challenging, but that doesn’t mean it should not be done. However, I see almost no interest or attention paid by almost all 3D printer manufacturers to this issue.

What can be done? I can think of a few things:

Design 3D printers to be more easily vented. This could mean enclosed chambers with ventilation ports of standard sizes, for example.

While HEPA filters don’t do the whole job, perhaps there are better filters that could be used instead? Yes, they may be more expensive, but what is the cost of safety?

Someone could produce an easily attachable 3D printer add-on that would, say, hook up to the hot end and slurp up emissions as quickly as they appear. This could lead to a filter, or an external ventilation system.

Materials could be designed to dramatically reduce emissions through ingenious chemistry. Some manufacturers are starting to do this, but most are not.

Materials could be labeled with standard words describing their emissive characteristics. Today I cannot choose filament based on how “bad” it is, but I should be able to do so.

Nothing is going to happen until more noise about this issue is made. Please make some!

Via UL, Taylor Francis Online and Taylor Francis Online

We were able to view video footage of the 3D printing hair-caught incident from last week and have determined exactly how it occurred, and how to prevent it from happening again.