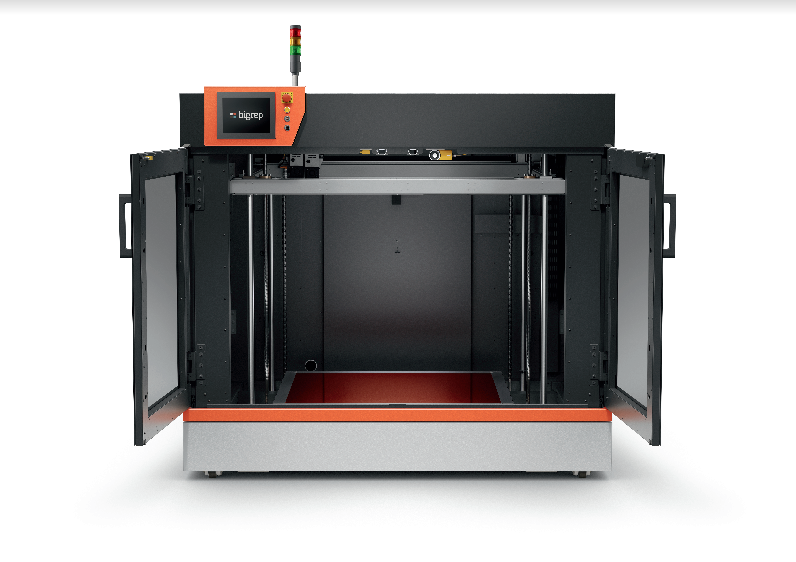

![The BigRep EDGE [Image: BigRep]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a2db9fbf1.png)

BigRep has announced two new MXT-powered industrial 3D printers: the PRO and EDGE.

Teased for months and unveiled today at formnext, Germany-based BigRep is introducing the machines featuring its Metering Extruder Technology (MXT) and CNC control systems and drives by Bosch Rexroth. The new systems target applications in the automotive, aerospace, consumer goods, and manufacturing industries with their high-performance material-capable PRO and EDGE systems.

BigRep MXT, says the company, “establishes a clear separation between filament feeding and melting and molten extrusion, which allows for full control over the amount and speed of material extruded at any given time.” Each of the new systems is fitted out with two MXT heads that enable faster filament throughput coupled with repeatability and precision. With its 0.6mm nozzle, the PRO can exceed print speeds of 600 mm/s, while with the same diameter nozzle, the EDGE can output 1,000 mm/s.

Along with MXT, BigRep highlights its partnership with Bosch Rexroth in incorporating CNC control systems and drives, “making 3D printing a truly IoT-ready machine with full connectivity and data.”

“Thanks to professional control systems technology, 3D printing is establishing itself as an industrial manufacturing application,” said Thomas Fechner, Director of the Business Unit New Business at Bosch Rexroth. “In terms of hardware, the CNC control system by Bosch Rexroth is delivering the necessary performance, precision and durability. In our development partnership with BigRep, we are advancing the potential of 3D printing for its use in the environment of the Factory of the Future.”

The BigRep PRO, available now for order, is the smaller of the two new systems — but like with what we’re familiar from BigRep, that ‘smaller’ still means big, with a one-cubic-meter build envelope. A heated print bed and temperature-cooled spool chamber have the PRO ready to print large-scale industrial parts with high-performance materials.

Its larger counterpart, the BigRep EDGE, offers a 1500 x 800 x 600 mm build envelope able to provide a 200C controlled environment in the chamber, and up to 220C in the print bed. “Specifically designed for high-end, high performance materials in large-scale format, allowing for end-use parts, functional prototypes and composite tooling,” the EDGE is slated for a Q2 2019 release.

“This new technology delivers the type of innovation that the industry has been awaiting, as our groundbreaking MXT® system makes our new printers five times faster – with greater precision and quality – than current extrusion speeds. This is one giant leap for additive manufacturing, allowing BigRep customers to make full use of today’s most advanced large-scale 3D printing technology,” said BigRep CEO, Stephan Beyer, PhD.

We’ll be looking forward to learning more about the new machines at formnext this week, where BigRep will be exhibiting in Hall 3.1, booth E20.

Via BigRep