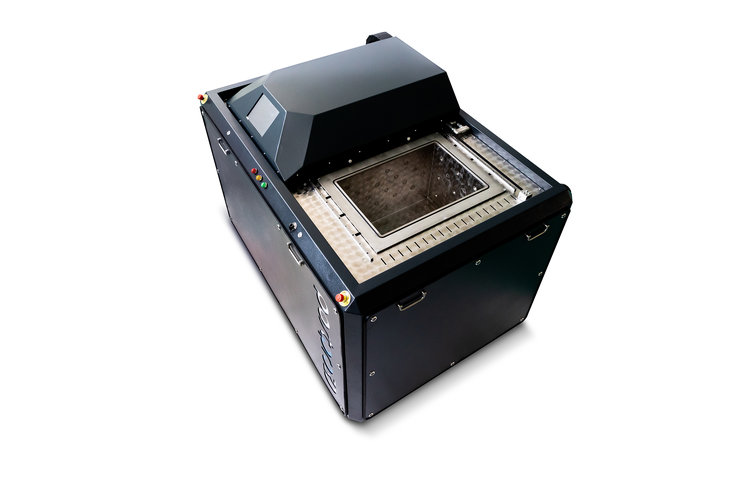

![[Image: AMT]](https://fabbaloo.com/wp-content/uploads/2020/05/Postpro3d_img_5eb0a318dc883.jpg)

Mitsubishi Electric continues with its momentum in additive manufacturing, partnering with Additive Manufacturing Technologies (AMT).

Both partners have been busy lately, with Mitsubishi Electric recently announcing its intent to introduce a new metal 3D printing system and AMT just this week formalizing its expansion into the North American market.

Bringing Mitsubishi’s focus toward the polymer side, the company is working with AMT to provide an integrated automation solution to the PostPro3D, AMT’s 3D printing post-processing machine. The announcement notes:

“This is based on Mitsubishi Electric’s MELSEC iQ-F Series compact PLC, HMIs, SCADA and MELFA articulated arm robots offered as a system option. AMT’s PostPro3D machine fully automates surface finishing of 3D printed parts, skyrocketing productivity from a few parts finished every hour up to hundreds of parts per hour.”

Addressing two major issues in the finishing of 3D printed parts — post-processing and automation — the PostPro3D is designed to ease process and reduce costs for industrial users.

Working with Mitsubishi Electric is a strong move from AMT, as Co-Founder and CEO Joseph Crabtree shares a look at the strategy behind the partnership with us:

“We chose an established automated partner in Mitsubishi Electric to enable us to realise our DMS (Digital Manufacturing System) vision,” Crabtree tells Fabbaloo.

“This fully automated production line for post processing has several complex automation elements that benefit from Mitsubishi Electric’s expertise. Currently we are offering stand alone post processing solutions in the form of PostPro3D (Smoothing) PostProCol (Colouring) as well as PostProDP (Depowdering) in addition to fully integrated solutions customised for our customers’ demanding requirements.”

As AMT continues to globalize operations and additive manufacturing is brought into workflows worldwide, partnering with an established, well-known large player opens up additional opportunity. A growing focus on meeting standards is focusing a keener eye on certifications to even out the playing field for new technologies brought into traditional manufacturing operations and applications.

“It was important to form a partnership with a globally recognised player and once that could meet all of our worldwide certification requirements from CE to UL. This is very important given the industrial end users that AMT work with. Additionally Mitsubishi are becoming increasingly active in the AM space and AMT feel that they synergies between the two companies can be leverage to unlock the true potential of AM through automation,” Crabtree tells us.

He noted that 30-70% of total manufacturing costs have often been attributed to manual post-processing. Automating the finishing process has the potential to substantially reduce the complexity of an involved series of processes. AMT’s BLAST (Boundary Layer Automated Smoothing Technology) physicochemical process incorporates “a series of pre-defined parameter sets and algorithms” to finish parts 3D printed via laser sintering, high-speed sintering (HSS), Multi Jet Fusion (HP’s MJF) or FDM 3D printing processes. Smoothing takes about 90-120 minutes, with part finishes of up to 1μm precision.

Mitsubishi Electric as a partner shows to be a good fit as AMT looks to bring its post-processing solutions to the European, North American, and Chinese markets. To reach these, Crabtree noted in the announcement, “we needed to build a system whose components are all accredited according to national governing regulations, such as UL and CE marking standards,” and the new partner “can offer us products that adhere to UL, CE as well as Industry 4.0 requirements.”

Integrated technologies are described as:

“PostPro3D is fitted with a Mitsubishi Electric power supply and low voltage switchgear, servo drives and motors, FR-D700 frequency inverters and an optional six-axis MELFA RV-F series robotic arm. These are connected to a MELSEC iQ-F Series FX5UC PLC, which offers high performances in a compact package, suitable for applications with limited space such as this.

The PLC is also linked to Mitsubishi Electric’s GOT2000 HMI operator terminal, which enables operator to set finishing parameters and monitor the process using Mitsubishi Electric’s advanced SCADA featuring 3D Graphics to ensure efficient operations and perform preventative maintenance. All these features helped AMT to create a fully automated and digitally connected machine.”

Via AMT