![Engineering properties of Mitsubishi’s new transparent 3D printing material [Source: Verbatim]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a2eff0cec.jpg)

Verbatim announced a very interesting glass-like 3D printer filament product.

Verbatim, owned by giant Japanese conglomerate Mitsubishi, is their arm for distribution of 3D printing materials. The company has produce a number of high-quality 3D print products in the past, and the new product is likely to be the same.

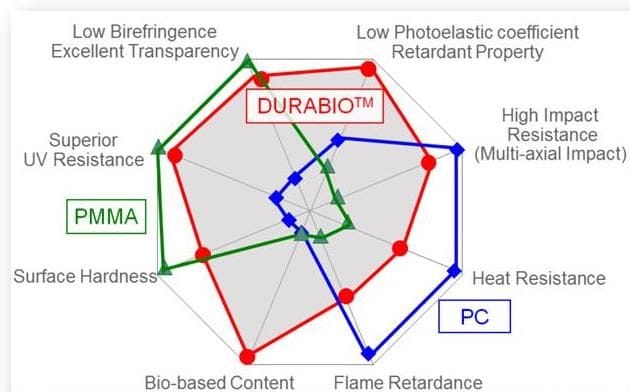

The company announced the availability of DURABIOTM, a specific combination of PC and PMMA polymers that has the interesting property of being near transparent. They explain:

“Mitsubishi Chemical originally developed DURABIOTM as a glass substitute and it has already been adopted in the automotive and mobile phone industries for items such as touch screens, console and dashboard trims and exterior radiator grilles. DURABIOTM is BPA free and is based on a renewable source, using isosorbide as the main monomer, making it particularly attractive to environmentally aware customers. By making it available as a 3D printable material, designers can now more easily develop functioning models or prototypes using the same material that will be used for mass production.”

In this image you can see how their DURABIO material has been used in another industry:

It appears to be glass, yet is not. Even better, it is highly UV resistant, as you can see in the chart at top. This means transparent objects can be safely implemented in outdoor situations where “clear” items are often used.

But making a clear object with a filament-powered 3D printer is not necessarily easy. In the industrial example, the DURABIO material is likely injection molded into these forms. This means that the internal structure of the object’s material is more or less uniform, and that greatly helps with the pure transparency.

Meanwhile, if the same material, DURABIOTM, is extruded on a 3D printer, you will almost certainly not obtain the same transparency due to the layering effects generated during deposition. Each layer exhibits a curved surface through which light can be refracted. And it’s not just on the surface layer, as there are internal extrusions that will also distort the light.

It may be possible with optimal print parameters to 3D print a fully solid object and then use post processing techniques to sand and polish the surface to something approximating “clear”, but I suspect there should be some experiments in this regard. I’m a bit surprised Mitsubishi / Verbatim have not yet provided images of clear print samples.

However, we intend on visiting them at formnext in coming days and hopefully we can examine some transparent samples first-hand.

This announcement is further proof of the power wielded by major chemical companies when they enter the 3D print space: these giant firms hold vast libraries of chemical formulas for many thousand of different materials, any one of which could be the next amazing 3D print material.

The door to Mitsubishi’s catalog is through Verbatim.

Via Mitsubishi Chemical and Verbatim