![[Image: Sinterit]](https://fabbaloo.com/wp-content/uploads/2020/05/Flexa-Soft-Pressed-Spongee_img_5eb0a3be52ae3.jpg)

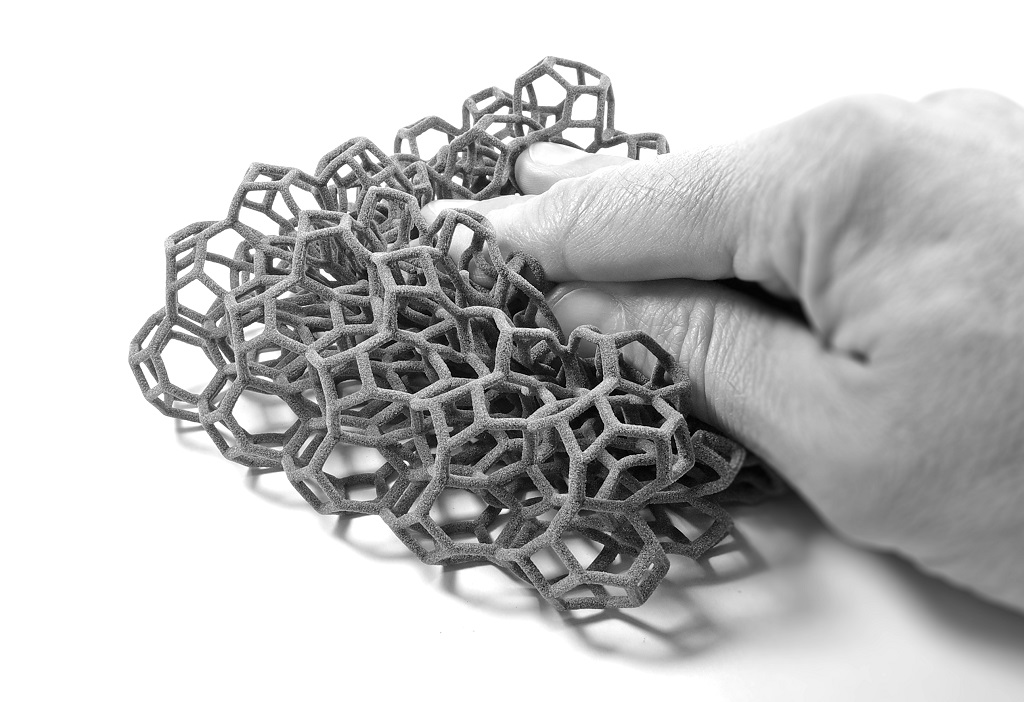

Sinterit’s newest material explores the softer side of SLS.

Flexa Soft joins the Sinterit material portfolio, alongside the recently introduced PA11 Onyx that joins the nylon side, offering a new degree of softness. Between 40 and 55 in Shore Hardness A scale, the squish is promising for a number of potential applications.

Among the initial use cases Sinterit highlights in the release are medical modeling for trial surgeries, fashion design (for even more flex than Sinterit’s already-on-the-market Flexa Black, which clocks in at 80-90 Shore A), and prototyping gaskets and sensory toys.

But wait, there’s more! The company notes:

“And it is not even close to the finish line. During Formnext 2018 Sinterit will launch a few more materials.”

With two new materials introduced in as many weeks, it’s hardly a surprise to hear that there’s more to come at the busy (and announcement-heavy) formnext coming up in just two weeks.

The new material introductions are not only a smart move as a broader portfolio appeals to a broader potential user base, but showcase market savviness by responding directly to customer demand.

“Our clients are very keen on experimenting with new powders and continually asking us to develop new ones, which will broaden the manufacturing possibilities of both Sinterit Lisa printers. We are very open to those inquiries because we are aware that the capabilities of SLS rapid prototyping have not been fully used yet,” noted Sinterit Co-Founder Konrad Glowacki.

![[Image: Sinterit]](https://fabbaloo.com/wp-content/uploads/2020/05/Fexa-Soft-Spongee_img_5eb0a3bf85d6a.jpg)

Flexa Soft — and the TBA portfolio announcements — will debut at formnext, showcased alongside PA12, PA11 Onyx, and fellow TPU materials Flexa Black and Flexa Grey. Of course the Lisa and Lisa Pro desktop SLS 3D printers will be there as well. Sinterit will be in Hall 3.1 at booth G41.

Via Sinterit