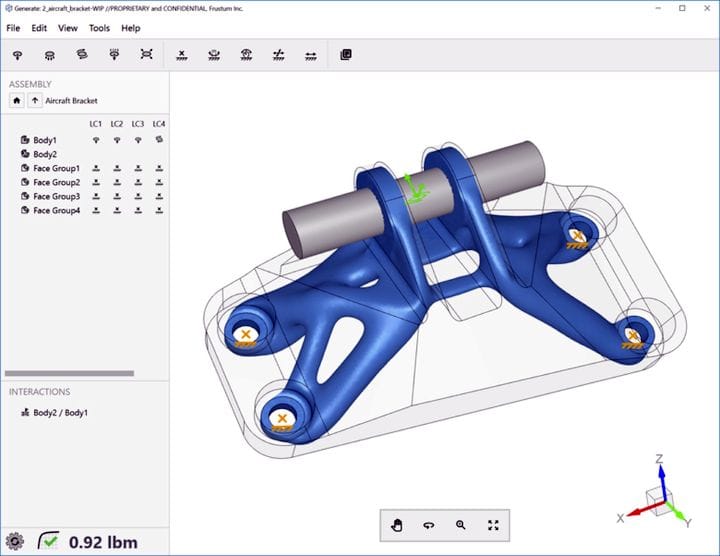

![Frustum’s GENERATE is now available for Windows users [Source: Frustum]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a59a4b218.jpg)

3D software maker Frustum released a Windows version of their powerful GENERATE tool.

GENERATE uses their “TrueSOLID” technology to automatically generate optimized 3D models that would typically be produced on metal 3D printers. The idea is to use simulation of forces on a shape to strengthen some portions and remove material from others to optimize the model’s geometry to best meet the specified mechanical needs.

I believe this is approach is the future of part design, as the increasing availability and familiarity of metal 3D printers enables a practical means to produce the part. In past years there were literally no practical ways to produce the highly complex parts generated by algorithms, so there was no need for such software.

Frustum is one company providing this capability with their TrueSOLID tech. We reported on this technology some months ago, but at the time they provided it only as a plug-in to popular 3D CAD packages and as a cloud service. This was (and is) quite a serviceable approach, as most parts are indeed designed within said CAD packages.

But now they’re offering another option.

The company announced a standalone Windows version of GENERATE. However, although they don’t say so, it is likely this software connects their cloud system to perform the extensive calculations required to provide for real time finite element analysis. If they didn’t, I’m not certain the magnitude of a desktop computer you’d require to get the job done.

As a standalone Windows app, GENERATE provides a number of features you would expect:

-

Native CAD file import

-

Single and multi-body optimizations

-

Multiple loads and constraints

-

Realtime FEA

-

Standard and user-defined material library

-

Interactive design changes

-

Windows 64-bit multi-threaded architecture

-

STL export with user-defined resolution

-

Optionally GPU-enabled with NVIDIA

Frustum explains the product:

”Built on its patented generative engine, TrueSOLIDⓇ, GENERATE couples advanced topology optimization and simulation algorithms with real-time interaction to quickly produce high-performing, ready to manufacture mechanical designs. It is functionally parametric and facilitates perfect blending of generative geometry to traditional surface-based CAD with engineering precision. The technology is currently being commercially licensed to Siemens PLM software and integrated into Siemens NX and Siemens SolidEdge. “

The idea of an interactive, real-time analysis is quite powerful. Normally the considerable calculations involved in FEA processing require a “drop off and pick up later” approach that would certainly stunt the creativity of a designer.

Instead a real-time solution allows the designer to work interactively with a model to tweak it in ways likely not discovered if using a batch FEA approach. I’m convinced that as computing power increases in capacity and costs lower, this will become the standard approach for developing parts.

The company says the new Windows version is available now, but they don’t provide standard pricing publicly and ask that you contact them for a quote.

Via Frustum

[UPDATE] Frustum CEO Jesse Coors-Blankenship reached out to us and clarified the computational approach used by GENERATE on Windows:

Just to clarify, Generate for Windows does not require connecting to our cloud platform though we may provide the option to in the future. Stay tuned!

A manufacturing-as-a-service company has developed a way to 3D print continuous carbon fiber in a production setting.