![Farsoon’s vision of 3D print manufacturing is far more than their HT1001P CAMS device [Source: Farsoon]](https://fabbaloo.com/wp-content/uploads/2020/05/farsoon-cams-ov_result_img_5eb0a4f9dc9b5.jpg)

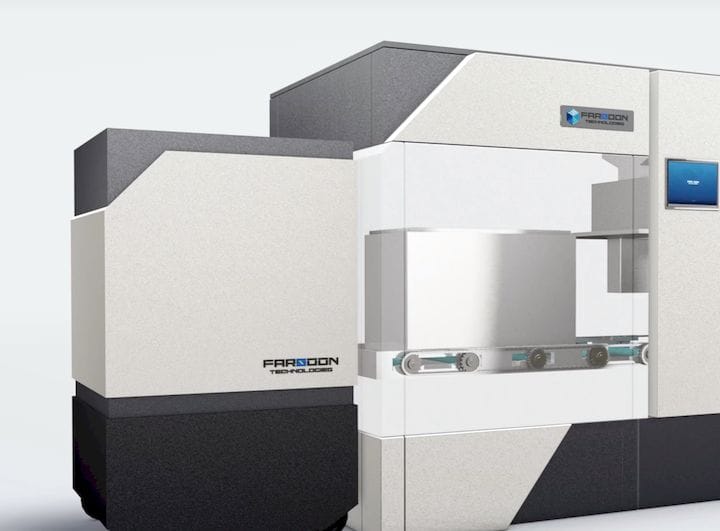

Farsoon has released a new polymer 3D printer, the HT1001P CAMS system.

The key to the HTP1001P is the “CAMS” part of its name, which is an abbreviation of “Continuous Additive Manufacturing System”. That is the design philosophy in this device: to directly integrate it into a fully modern manufacturing process.

![Farsoon’s polymer production concept [Source: Farsoon]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a4fa5f9f9.jpg)

This is far more than just another 3D printer; the entire device is literally designed for continuous operation, pre- and post-printing. There are multiple features in their system design to facilitate this objective, some of which I’ve never seen previously.

Let’s start with the printer itself, which is the core of the concept. It’s an SLS-style machine, using lasers to selectively sinter polymer powders of various kinds. The HT1001P’s build volume is quite large at 1000 x 500 x 450 mm, and uses modular build chambers.

![Rolling recoater concept in the HT1001P CAMS 3D printer [Source: Farsoon]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a4fab08ab.jpg)

I am very impressed with their unusual powder recoating process. Most SLS devices have an adjacent store of powder, which is lifted slightly, and then pushed with a blade across the actual build volume. Not so with the HT1001P. Instead they have a radically different overhead mechanism that seems to spray powder across the surface in a rough fashion. Then a roller steams over the build surface to flatten the powder. This could be a lot faster and more accurate than a blade approach. Even better, the roller is bi-directional, saving considerable time.

The modular build chamber means that the completed print jobs are quickly moved automatically from the printer to the cooling unit. Yes, there are multiple units in this CAMS, as you can see here. above.

After cooling the build chamber is moved to the “Part Breakout Station”, where the parts are automatically cleaned of loose powder using a combination of vibration and an “air knife”.

![3D print powder management concept [Source: Farsoon]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a4fb0f6d5.jpg)

All unused powder is collected at all stages and cycled through to the powder station in a completely closed loop process. No powder will be lost, and precise mixes of fresh and used powder can be achieved.

![Post processing stages after 3D printing [Source: Farsoon]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a4fb5544a.jpg)

A robotic system collects completed prints and can move them along to post-processing stages, where parts can be inspected, smoothed, painted, or treated in various ways. Finally, the parts can then be automatically routed into further stages of a manufacturing process to, for example, be included as part of an assembly.

![A robotic system can move 3D print chambers between equipment [Source: Farsoon]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a4fb9e33f.jpg)

Farsoon’s vision for continuous additive manufacturing is far-reaching. While I’ve seen some elements of their solution in other vendors’ products, I have not seen all of these put together in such a coherent manner.

![Farsoon’s vision of a 3D print factory [Source: Farsoon]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a4fbe633a.jpg)

Looking at their concept video it is apparent that if built, this system could literally be an “Anything Factory” that merely needs 3D models as input to continuously produce products.

Via Farsoon

A manufacturing-as-a-service company has developed a way to 3D print continuous carbon fiber in a production setting.