![Liquid crystal polymers could enable ultra-strong 3D prints [Source: ETH Zürich]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a688e03ad.jpg)

I’m reading a paper describing a new way to 3D print with molecularly oriented liquid- crystal polymers.

The research, performed by staff at ETH Zürich, could be of great interest to 3D printer operators, as it proposes an entirely new way of achieving strong parts.

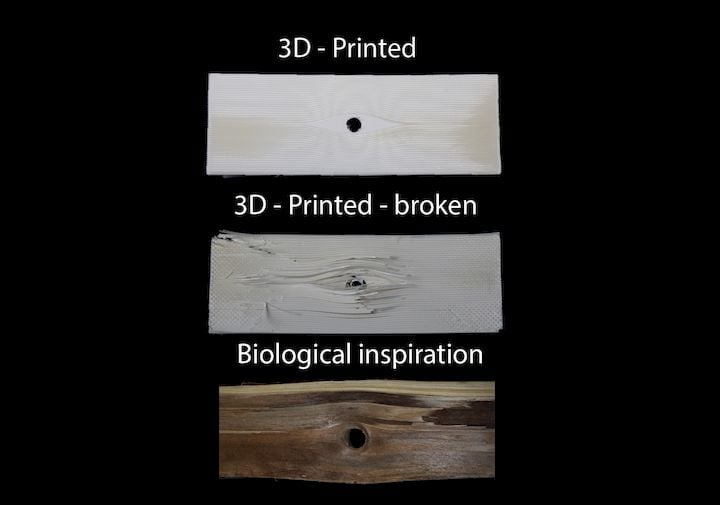

Their approach seems to use two key methods. First, they’ve concocted a unique liquid crystal polymer (LCP) that uses molecular chemistry to automatically form short polymer chains, shaped like rods. Imagine this to be something like chopped fiber, except at a molecular level.

Secondly, they employ a very unusual 3D printing technique, one that you can see in this short video:

If you watched the video, you’d see a beginning and end sequence that appears quite normal, but the middle section is different. At first I thought there was a mistake, as the extruder was simply zipping to and from without regard to whether the extrusion was actually adhering to the surface.

But it seems that is their intent. These loose strands of material are what is desired. They are then covered up by subsequent “normal” layers and thus embedded within the print.

What’s going on here is that the molecular rods are aligned through speed, thermal and chemical action as they pass through the hot end nozzle. This means that these microscopic fibers are aligned with the path of the extrusion, much like you would extrude a solid wire as is done on some exotic 3D printers.

These strands are significantly stronger than normal extrusions. According to the research, it seems they are pretty much stronger than anything short of continuous carbon fiber reinforced polymer. And metals, I presume.

It seems that in order to use this approach one would not only have to provide the appropriate chemical mix, but also make some interesting changes to the slicing program to ensure the system motions precisely develop the required molecular effects, and that the output matches the desired axes of strength required by the part itself.

As this is still research, there is no product – yet – that can do this feat. It seems to me there will be considerably more research required to refine this to a production state.

But if successful it could mean a new class of ultra-strong materials that could, in theory, be 3D printed by almost any extrusion device. That opens up many possibilities.

There is another aspect here, and that is whether this approach could be employed by existing 3D printers using conventional materials: what if you 3D printed in the same manner? I don’t think it would work because the research approach was devised to leverage both techniques together. In other words, you probably won’t be able to “just do this” with PLA, for example, as it wouldn’t contribute strength-wise at a molecular level.

Meanwhile we await developments.

Via ETH Zürich

A research thesis details the incredibly complex world of volumetric 3D printing. We review the highlights.