Charles Goulding and Andressa Bonafe of R&D Tax Savers discuss the connections between LEGO and 3D printing.

Having worked with numerous architects, engineers and designers, we came to realize that many of them grew up playing with LEGO, Kinetics and Erector set construction toys. Founded in 1932 in Denmark, LEGO has gained international renown, spreading its iconic bricks all over the globe. The toymaker has achieved such great success by constantly resorting to innovation. Recent and exciting developments at LEGO include:

- A huge new LEGO theme park in Goshen, New York,

- A quest for more environmentally suitable materials, and,

- Increased 3D printer applications.

Toymakers and related companies should take advantage of U.S. R&D Tax Credits to increase their chances of success in a competitive, ever-changing industry.

The Research & Development Tax Credit

Enacted in 1981, the federal Research and Development (R&D) Tax Credit allows a credit of up to 13 percent of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- New or improved products, processes, or software

- Technological in nature

- Elimination of uncertainty

- Process of experimentation

Eligible costs include employee wages, cost of supplies, cost of testing, contract research expenses, and costs associated with developing a patent. On December 18, 2015, President Obama signed the bill making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit can be used to offset Alternative Minimum Tax and startup businesses can utilize the credit against $250,000 per year in payroll taxes.

LEGOLAND Park New York

Scheduled to open in 2020, LEGOLAND New York will be the ninth and largest LEGO-themed park in the world, with over 150 acres. In addition to more than 50 rides, shows, and attractions, the new LEGOLAND will have a 250-room hotel designed to provide a LEGO world immersive experience. With an estimated cost of $350 million, it will be Merlin Entertainments’ largest investment in a single park to date, generating over 1,300 jobs.

Existing LEGOLAND locations include Denmark, Germany, the United Kingdom, Dubai, Malaysia, and Japan, as well as two U.S. parks in Florida and California. The original park alone, in Billund, Denmark, draws nearly 2 million visitors annually.

LEGOLAND New York will be located in the town of Goshen, just 60 miles northwest of New York City and only a few minutes away from the Woodbury Commons discount shopping complex – which is, perhaps surprisingly, the most popular destination for New York City tourists, with over 13 million visitors each year.

Positioned within a two-hour catchment of 23 million people, LEGOLAND New York will be easily accessible for visitors from the Northeast. Goshen is also just a seven-hour drive from Toronto, Canada, which points to a potential for international tourists as well.

LEGOLAND New York will be divided into eight themed lands, including “The Factory”, which will take visitors through the LEGO manufacturing process. This could be a great opportunity to portray the game-changing role of 3D printing in the toy industry.

Environmental Concerns

Growing environmental concerns regarding plastic waste are impacting every business that utilizes plastic materials. In an effort to develop more sustainable products, LEGO has over 100 technical experts striving to create alternative solutions that would diminish its carbon footprint.

The toymaker aims to overcome its dependence on petroleum-based plastics and rely solely on plant-based, recycled materials by 2030. This is not a simple task, especially as the final product needs to snap together easily and retain vibrant colors in addition to being safe for children and highly resistant to breakage. 3D printing may facilitate experimentation with new materials and help create new and improved manufacturing processes that would further enhance sustainability.

LEGO 3D Printing

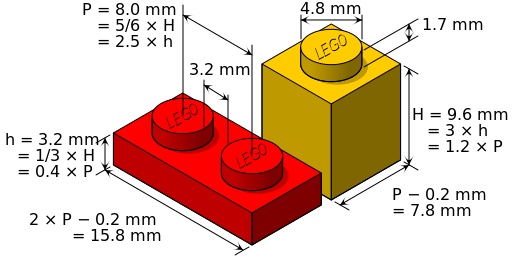

There is a wide variety of LEGO 3D printing models available, which enable future designers, architects and engineers to concurrently learn conventional design concepts and work on their 3D printing skills. 3D printed LEGO pieces include super-sized figures and inventive variations of existing products.

For the toymaker, 3D printing can be seen as an interesting business opportunity. There has been a significant decrease in brick and mortar retail toy stores, so Internet-based, content-rich LEGO model resources could be an innovative alternative to reach the market.

Conclusion

Recent developments at LEGO point to the fact that toy companies must turn to innovation in order to remain competitive. LEGO’s strategies, including a new LEGOLAND park and increased environmental concerns, could benefit from 3D printing technology. 3D printing models could also represent an interesting business opportunity and an innovative strategy to reach a wider market.

‘Tis the season to celebrate the best of 3D printing.