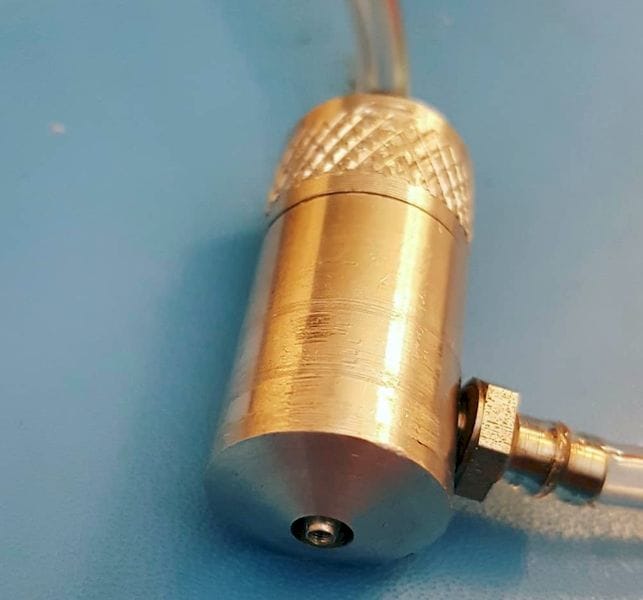

![The Z-Catch 3D printer nozzle removal tool [Source: Z-Catch]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a7d26b280.jpg)

There’s a new Kickstarter project with a tool that many desktop 3D printer operators could use.

This a nozzle removal tool (and installer, too). It is a very simple, but specialized device that could overcome common issues encountered by 3D printer operators.

What is the problem being solved?

Today’s filament-extrusion 3D printers all push thermoplastic through a tiny nozzle. These nozzles have for most of the lifetime of 3D printers been installed at the factory and left there until the machine is retired.

But that’s changed in the past few years with the introduction of new and exotic 3D printing filament materials.

Operators demanded stronger materials, and they got them: materials providers devised composite filaments with mixes of metals and carbon fiber to increase strength. We’ve even seen a few products using carbon nanotubes as the strengthening agent.

The problem is that these materials contain substances that are in some cases substantially harder than the common brass material used to make most 3D printer nozzles. Thus over time the nozzles would slowly erode and you’d find your 0.4mm diameter nozzle is actually now 0.523mm in diameter, compromising print quality.

Another effect has recently emerged: larger diameter nozzles.

This has resulted from the enormous build volumes of some 3D printers. While they would certainly work with nozzles of conventional diameter, the print times would be ridiculously long. The brilliant idea was to swap in a nozzle of larger diameter, say 0.6mm, 0.8mm or even 1.0mm to allow for faster prints. And indeed, these can dramatically speed up prints at the cost of resolution.

However, all of these scenarios involve the need to remove and replace nozzles periodically.

And doing so is actually quite a pain.

There’s a process involved in doing so, which goes something like this:

- Remove housings around the heater block if present

- Heat up the hot end to operating temperature

- Clamp the heater block with a large wrench

- Grasp the hot nozzle with another wrench

- Carefully turn the nozzle wrench – but NOT the block wrench – to release the nozzle

- Make sure you put a safe material over your print surface otherwise the hot nozzle may drop and melt your print bed

And that last point tells you something about why I don’t particularly like swapping nozzles.

The installation of a replacement nozzle is a similar process, but the important thing is that it must be done while the machine is hot in order to ensure it is securely mounted.

If you somehow accidentally rotate or move the heater block, you may introduce a small gap between the block and the cooling zone, which could result in a nasty problem afterwards.

In some cases it’s actually tricky to find the right size of wrench to fit the heater block. It’s just not a fun experience.

Now there seems to be a solution to all these matters with a new Kickstarter project.

![The Z-Catch 3D printer nozzle removal tool [Source: Z-Catch]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a7d2a22dd.jpg)

Miami-based Samuel Caillouette has developed a unique metal tool that’s specifically for changing hot 3D printer nozzles.

Nozzle Removal Tool For FDM 3D Printers

Samuel is raising funds for Nozzle Removal Tool For FDM 3D Printers on Kickstarter! This invention is a nozzle removal tool for FDM 3D Printers. Will allow the user to change different sized nozzles safely.

As you can see in the video, it’s trivial to swap nozzles, even when hot.

Caillouette is offering the design to the public at the low cost of USD$30, which also will include a 9-piece socket set. Given the frustration I’ve had with nozzles, this could be a good purchase.

3D printer operators already have a ton of specialty tools, and I think this one should be added to your collection.

Via Kickstarter and Z-Catch