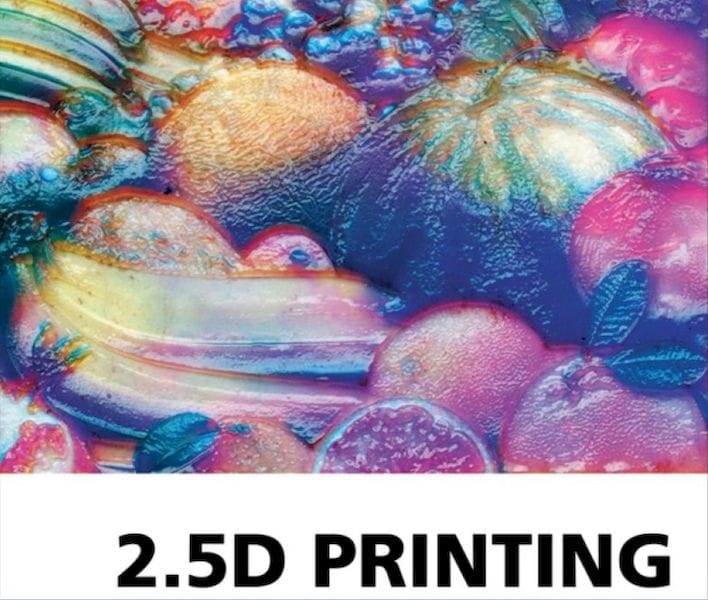

![Could 2.5D printing techniques be used in 3D printing? [Source: Amazon]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a65bb6aa3.jpg)

This week’s selection is the informational “2.5D Printing: Bridging the Gap Between 2D and 3D Applications” by Carinna Parraman and Maria V. Ortiz Segovia.

Readers of this publication are no doubt familiar with the concept of 3D, and everyone is certainly familiar with 2D concepts. But what is 2.5D? Where are the boundaries between the two?

In some CAD/CAM systems, 2.5D means simulating 3D by layering very coarse chunks in a step-like fashion. That’s not what’s being discussed in this book.

Instead they’re discussing the science of using surface elements to simulate 3D. This can be done through ingenious applications of color and texture.

They explain their approach:

“This book demonstrates that 2.5D printing provides the relationship of materials, texture and surface. The extra half dimension places the reader halfway between visual and haptic sensing, asking her or him to distinguish amongst thousands of different materials, textures and colors.

The book provides a means to define, measure and assess a ‘materiality of surface’, meaning a qualitative and/or quantitative evaluation of the aesthetic, informational and other qualities of a surface. Where does the rubber meet the road? Perhaps nowhere more so than in the description of the texture. The authors see texture as ‘the microstructure details that can be perceptually distinguished from one surface property to another’, usually through sight or touch.”

If this doesn’t make sense, consider how an animal may use its colors to camouflage itself against a background. That’s an intelligent use of texture: a 3D object (the animal) visually disappears into a texture, altering your perception of the scene.

The book covers several important aspects:

-

A definition of 2.5D printing, including concepts of texture, color, imaging, methods and much more.

-

A history of 2.5D use to portray depth, relief and other visual tricks.

-

A review of current techniques and approaches for implementing 2.5D surfaces, including both manual and digital methods.

-

Thoughts on where 2.5D may go in the future.

-

Fourteen case studies of 2.5D use.

My interest in this is in how these techniques and practices could be adapted for 3D printing. In most 3D prints there is little attention paid to the surface: it’s simply whatever was devised in the 3D model, and emerges from the 3D printer in a single material. There is almost never any ingenuity in the design of the surface to accomplish deeper purposes.

With the increasing availability of multi-material 3D printers offering the ability to significantly alter the colors and tactile feel of a 3D printed surface, it may be time to investigate the 2.5D practices to see if they could be adapted for innovative 3D printing use.

If amazing visual and tactile feats can be accomplished in a 2D medium using 2.5D techniques, what could be possible in a 3D medium?

Read the book and find out.

Via Amazon

This week’s selection is “3D Printing Projects” by Dorling Kindersley, a.k.a. “DK”.