![One of the first 3D prints using Aurora Labs’ new LFT metal 3D printing process [Source: Aurora Labs]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a6de6bd2f.jpg)

Aurora Labs marked a milestone on their journey towards large-scale industrial metal 3D printing.

The Australian company announced they’ve managed to complete testing of their new Large Format Technology (LFT) metal 3D printing process. This process is different from the process used on their initial machine, which was primarily used by research and educational institutions.

Why develop an entirely new process? The reason is that Aurora Labs is pursuing an entirely different market that requires a vastly different 3D printing process. They’re hoping to address the incredibly expensive problem of providing large-sized metal replacement parts for remote industrial operations, in such areas as mining or shipping.

It’s a great concept, but to be properly economical they’ve set themselves a rather hard target: 3D printing at least 1,000kg of metal parts per day.

That statistic is significantly larger than anything on the market today and obviously requires an entirely new process to do so. That’s why they developed LFT.

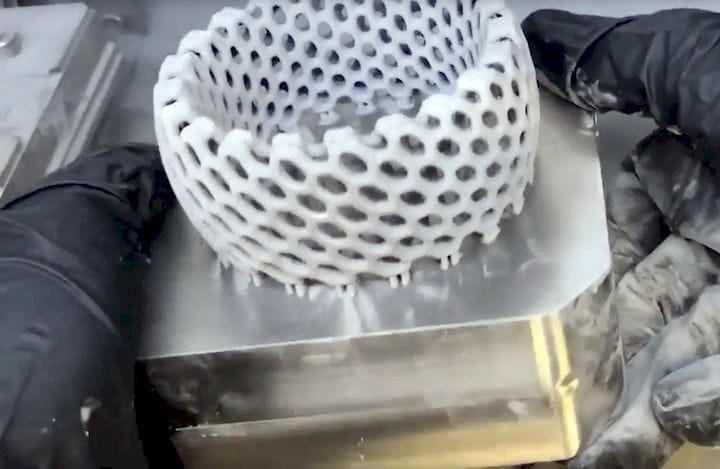

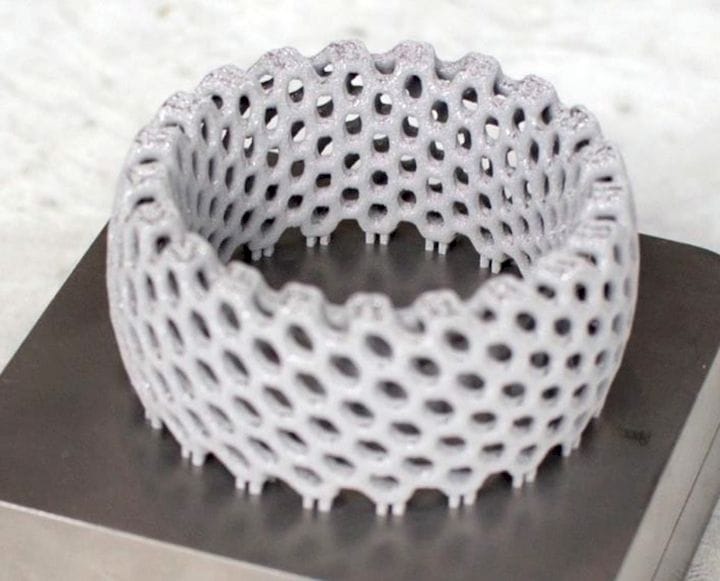

This week’s announcement deals with their first successful prints on a prototype “Alpha test” device with the LFT technology. No, they did not hit 1,000kg’s of metal prints in a day. That’s to come later, as this stage is merely to demonstrate that the technology works at a lower scale.

The recent test showed they were able to successfully 3D print an object with the Alpha machine’s 200 x 200 x 200 mm build volume at the rate of 15.88kg per day, or 0.662kg/hour. That’s about 63X slower than their ultimate target, but it’s first step of many to come.

Aurora Labs explains:

“This showcases an ability to execute complexity in printing and indicates that once the full sized Rapid Manufacturing Printer is fully built, the technology’s ultimate target print speed of 1000kg/day is achievable through scaling, rather than further proving the fundamental technology.”

This video shows some of the printing process:

It’s interesting to note some of the characteristics of the LFT process that we had not previously seen:

![Digging a finished metal 3D print out of powder [Source: Aurora Labs]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a6dec6eed.jpg)

It’s a powder-based process, like most other metal 3D printing processes

![Aurora Lab’s LFT process in action [Source: Aurora Labs]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a6df19d41.jpg)

Lasers are used to fuse loose powder

A print plate is required, and likely support structures too, although none are seen in this particular print

There is no powder recoating process visible in the video

Recoating is the process of laying down a precisely flat layer of additional powder for the laser to build into the next object layer. Recoating is one of the slowing aspects of metal 3D printing: every layer must wait for fresh powder to be deposited.

A similar delay occurs in most resin 3D printers, as the newly fused layer must be slowly peeled off the bottom of the clear resin tank. This adds time to each layer’s processing. However, several companies have invented ingenious ways of eliminating or significantly reducing this effect, drastically speeding up their print process.

I’m wondering if Aurora Labs has figured out a way to do something similar with metal 3D printing? Do they have some magic method to deploy fine metal powder that takes very little time? If so, that might explain their confidence in being able to 3D print metal at such high speeds.

We don’t know. But I’m sure Aurora Labs will eventually reveal more of their secrets. For now, they have hit a key milestone.

Via Aurora Labs

Aerosint and Aconity have proven out their work in multi-metal powder deposition 3D printing.