![[Image: Ines Álvarez Fdez via Unsplash]](https://fabbaloo.com/wp-content/uploads/2020/05/photo-1514063364532-5abd25e38290_img_5eb0a89c5bbe4.jpg)

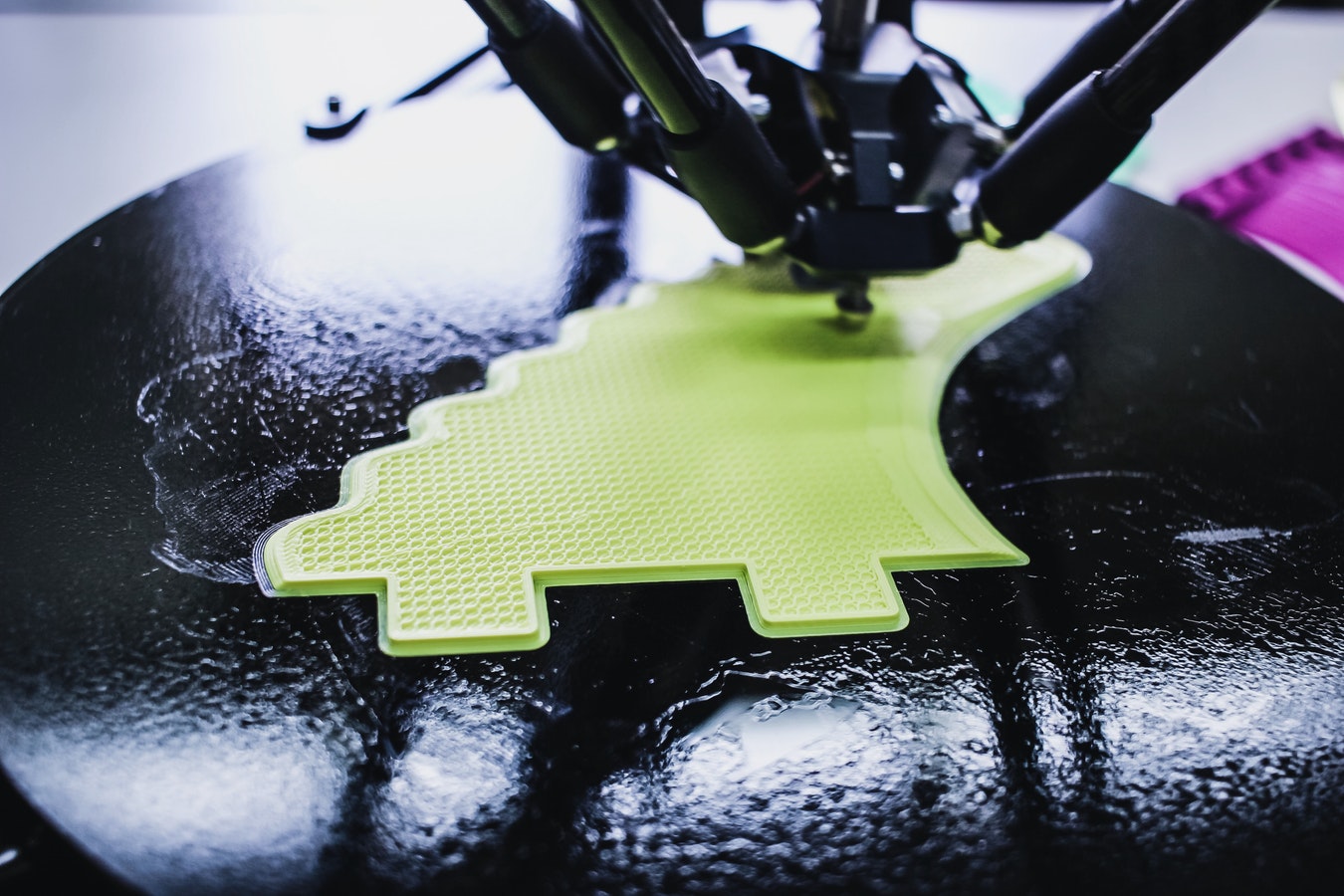

Manufacturing is embracing 3D printing, due to the vast number of choices for materials. Though plastic is the most popular choice, you have many more options. You can use materials as wide-ranging as ceramics and food in 3D printers. Properties of the materials will help you choose the right ones for your next project.

1. Polyvinyl Alcohol

Polyvinyl alcohol, or PVA, dissolves in water, which makes it an ideal material if you need to print supports for a project. After printing, submerge the project in warm water, and the PVA supports will vanish, leaving you with the base project. It’s ideal if you require structural support in small, hard-to-reach places where hand removal of the supports would be difficult. Printing prototypes is another way to use PVA. The downsides to PVA are its expense and tendency to clog nozzles.

2. Polylactic Acid

If you prefer an easy-to-use, biodegradable product, use polylactic acid, PLA. This material comes from organic sources such as cornstarch or sugar. Choose hard or soft varieties, depending on the application. This versatile plastic alternative may replace ABS plastic for many of those uses in the future as an environmentally friendly alternative. However, soft PLA only has a limited number of colors available, compared to ABS.

3. Acrylonitrile Butadiene Styrene

The most common plastic used is the low-cost, durable acrylonitrile butadiene styrene, ABS. This material requires three layers to produce a millimeter of thickness. It also requires a minimum of one millimeter of wall depth. Frequently, manufacturers use this plastic for toys and other long-lasting applications. You have many colors to choose from with this spaghetti filament plastic 3D printing material.

4. Metal Powder

The printer binds metal powders, such as silver, stainless steel, gold, titanium, nickel, steel and aluminum. Firing completes the process to create a strong, metal product. Metal powder is often useful for creating intricate designs, such as in jewelry or medical equipment. Using metal powder in a 3D printer eliminates the need for casting and processing. These small applications are ideal for 3D printers. For larger metal creations, CNC machining may be a better option, with an accuracy to the nearest 0.001 inch.

5. Resins

Resins can be transparent, white or black. Materials printed with the several types of resin require UV light curing after printing. Though the colors are limited, you have printable resins at your disposal. Resin can create highly detailed products, as it has 10 layers per millimeter.

6. Ceramics

Ceramic printing has two steps. After printing, the piece must undergo a glaze. Unlike other materials, ceramics do not allow for fine detail. Ceramics, though, are good insulators. Labs use many ceramic products for equipment. Watches, jewelry and biomedical parts are also products that may benefit from 3D printed ceramics.

7. Carbon-Based Materials

Carbon fiber is one of the newest materials for use with 3D printers. It is like graphite, but oxidation creates long fibers. Combining this with plastic yields a material that has the strength of steel, but is lighter and easier to work with. Graphite and graphene are other carbon-based materials. Graphene is an artificial form of graphite that acts as an excellent, lightweight conductor. Graphene has applications in LED lighting and semiconductors.

8. Polyether Ether Ketone Thermoplastic Polymers

Like carbon-based materials, polyether ether ketone, or PEEK, polymers are new to the 3D printing world. These polymers create dense products that can withstand heavy forces. Often, companies use PEEK products for piston components and bearings. It’s extremely wear-resistant and water-resistant. Though expensive, it is 80 percent lighter than metals, like steel. As technology further develops, the price of this high-quality, long-lasting organic thermoplastic polymer will decrease.

9. Nylon

Sturdy, durable and flexible, nylon is extremely popular for manufacturing a variety of pieces with 3D printers. Storage of this material is critical to the printed products. If unused nylon filament gets wet or stored in a humid environment, the details of the printed product could suffer. It also requires higher extruder temperatures — up to 518 degrees Fahrenheit. Manufacturers often print screws, gears, cable ties and bolts from nylon for a lighter, cheaper alternative to metal.

10. Polycarbonate

Like nylon, polycarbonate tends to absorb moisture. This material creates strong, flexible and heat-resistant products. Electronics cases and other heat-resistant applications are ideal for polycarbonate printings. Also, like nylon, polycarbonate requires a high-heat extruder and a heated bed. Products printed from polycarbonate can withstand temperatures up to 302 degrees Fahrenheit without affecting their designs. Store in a cool, dry place.

Many Materials, Many Applications

What you produce is only one facet of selecting 3D printing materials. You also need to consider other parts your printer needs, such as heated beds or cooling fans. Additionally, the build surfaces differ depending on the material. Use these features, in addition to your product selection, to help you choose the best materials for your next 3D printing project.

An inventive designer has developed a method for producing 3D paper objects using recycled paper and 3D printed molds.