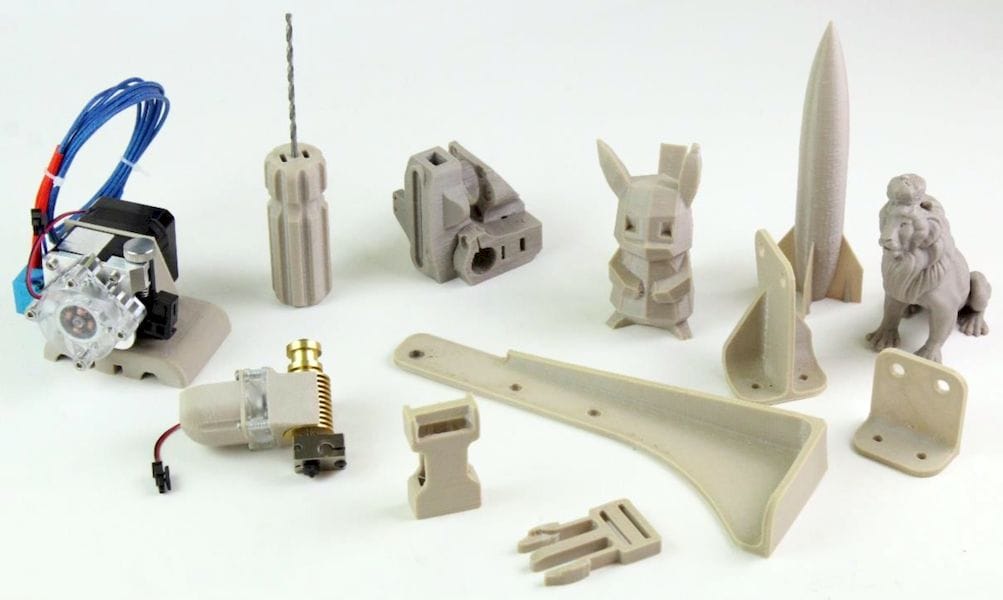

![3D printed PAEK parts [Source: E3D Online]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a98b3e508.jpg)

Recent interest in more exotic materials should drive a lot more partnerships in the future.

For many years the go-to materials for plastic extrusion 3D printers were ABS, PLA and a few others. However, these materials were developed eons earlier with other usage goals in mind. Why were they used for 3D printing? Simply because they were readily available in most locations and provided at least barely acceptable 3D print performance.

But they were definitely not optimum for many applications.

Why were no new materials developed specifically for 3D printing? There were a number of reasons, not the least of which was that the 3D printing industry was small and thus any market potential was small: why spend a ton of product development cash for a product that couldn’t sell widely?

But that scenario has changed in the past few years, particularly with the avalanche of inexpensive but highly capable desktop 3D printers emerging from manufacturers such as LulzBot, Prusa, AirWolf 3D, Raise 3D and many others. Some vendors have also pursued – and achieved – the development of higher temperature 3D printers.

These machines were not only widely used, but are also capable of 3D printing in a much wider range of materials.

But where are these materials coming from?

The traditional approach of simply using materials from existing product catalogs has continued, but sometimes it’s discovered that a particular material may not provide the best 3D printing performance or quality, in spite of the material’s otherwise excellent and desirable engineering properties.

What to do?

The answer is to tune both the materials and the target 3D printer to print the material more optimally.

But there’s a problem: while the 3D printer manufacturers are perfectly capable of tuning their device, they may not have the appropriate chemical knowledge and facilities to tune the materials.

By the same logic, a materials company can tune the chemistry, but is less able to tune the machine that material is targeted to print on.

Thus the need for partnerships: materials companies should reach out to 3D printer manufacturers and vice versa to create joint ventures intended to develop new materials that will be highly successful.

One great example of such a partnership is the work undertaken by E3D Online, makers of what seems to be current industry standard hot ends and extruders, and Victrex. These UK-based operations teamed up to develop a new “printable” PAEK polymer. They explain the problem:

The challenge with existing PAEK formulations is that they require complex heating systems, and typically exhibit poor interlayer adhesion. The combination of E3D’s 3D printing experience and Victrex’s polymer customisation expertise has allowed the two companies to develop a material with the exceptional properties of a PAEK polymer and remain very printable when used with new E3D developed high temperature printing hardware.

Congratulations to both for succeeding and providing the industry with a new, highly usable material. And as many 3D printers use E3D Online’s components, this could become widely used, at least in high temperature machines.

However, this is also a message to others in the industry who should be doing similar partnerships and are not. This type of relationship may be the best way going forward to provide suitable engineering materials for 3D printing: quality now counts higher than ever.

Via E3D Online