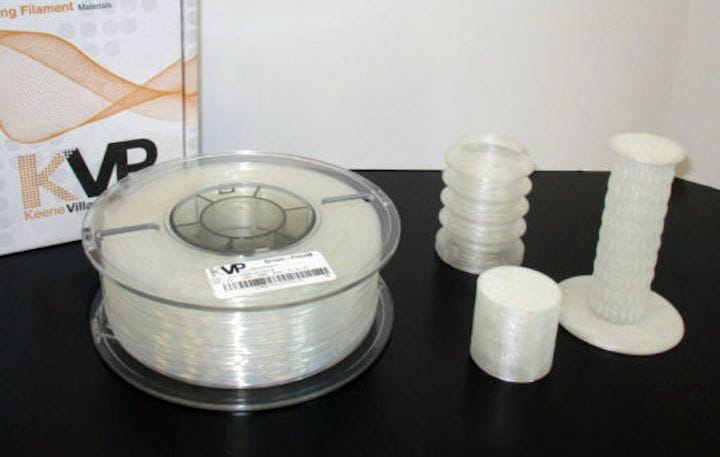

![A new set of flexible filaments from KVP indicates a change. [Source: KVP]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a91f1f4c4.jpg)

I saw an announcement of a set of new flexible filaments from Keene Village Plastics and had a thought.

Keene Village Plastics, or KVP, have been producing 3D printer filaments for many years, and they have an interesting corporate history involving being bought and sold by 3D Systems, selling to the public, then to OEMs, then back to the public. As of now you can consider them to be a typical supplier of good quality 3D printer filaments.

Their announcement related to three new flexible thermoplastic filaments:

- Summa -Flexx50 is a polyester-based TPU with a 50 shore D hardness; therefore, being a good general purpose grade for FDM. Summa-Flexx50 is chemical and abrasion resistant, and compatible with PVC and other plastics. The tensile strength between a printed part and injection molded part is within 4%.

- Semper-Flexx98 is a polyester-based TPU with a 98 Shore A hardness, suited for applications that are exposed to compressive loading or require good compression. Semper-Flexx98 is highly crystalline with low warpage and shrinkage. This product is a good general grade for FDM and is easier to print.

- Vexi-Flexx70 is a polyether-based TPU with a 70 Shore D hardness containing excellent hydrolytic stability with good mechanical properties. This TPU has low temperature flexibility, good abrasion and tear resistance, and is durable against microbial attack.

These are apparently available on 1kg spools in either 1.75mm or 3.00mm formats (which is a bit strange, as I would have thought they would issue 2.85mm filaments as that seems to have become the new standard for thicker filament diameters).

What I found quite interesting was that they are explicitly mentioning the shore hardness rating for each material.

“Shore” is an engineering scale by which the hardness of a material can be measured. It was devised by an Albert Ferdinand Shore (no surprise there), who built a measurement device in the early 1900s. The process involves determining the depth of a hollow indentation in a substance caused by a standard force. The larger the indentation, the more flexible the material.

Since introduction, the Shore concept has evolved into a more formal system, now defined by the ASTM.

Back to filaments.

In earlier days of desktop 3D printing one would typically purchase a rigid material, like PLA or ABS. An exotic material would be “Flexible”.

But wait – exactly how flexible was that “flexible” filament? No one knew, because at the time virtually no supplier ever stated the shore specifications for their material. One flexible filament might be “slightly bendable”, while another could be like overcooked spaghetti.

I suspect the shore value would even vary among batches of flexible material from some suppliers.

For those folks designing serious prototypes this was obviously a problem. They could not reliably predict the performance of their parts.

In some cases this forced use of more expensive industrial 3D printing equipment where vendors might actually provide proper specifications. One vendor in this space is Stratasys, whose Connex series allows the dynamic creation of materials by mixing hard and soft liquid resins. Their equipment is able to produce, I believe, up to 11 different shore values in this way.

But now that’s beginning to change. As the desktop 3D printing industry shifts from casual usage patterns to professional use, so too must the materials follow.

In that line of thinking, it seems clear why KVP prominently states the shore values for these three new products. And even better, they’ve released three new filaments with DIFFERENT shore values. You can choose between harder or softer materials as you require.

Now if your project requires shore 98 parts, you can be assured of getting them with KVP’s Semper-Flexx98, for example.

While this is a good start, this inevitably will end with a set of materials that completely covers the shore spectrum.

Via KVP

An inventive designer has developed a method for producing 3D paper objects using recycled paper and 3D printed molds.