I’m looking at a new German startup company that hopes to develop a kind of medically-focused 3D printer.

Kumovis, based in Munich, was founded only a couple of years ago. The story is that they were founded when experimenting with developing medical implants on then-available desktop 3D printers, but found it difficult or impossible to do so properly.

Wait, how could you not be able to print objects on 3D printers? You could, and even do so with high temperature materials, like PEEK. However, medical standards are quite high, and not unreasonably so.

The problem is that if you’re putting something into the human body, you must know exactly what it is made of. And this means not only the material you intend to make the object from, but also any contaminants that just happen to stray into the object during its production.

That’s a big problem.

Virtually all thermoplastic 3D printers have no means to control contamination. At best you might find a few machines using advanced filtration systems to capture emitted nanoparticles before exhausting them into the room where you’d otherwise breathe them into your lungs.

In fact, a great many desktop 3D printers still to this day do not even have a basic enclosure, thus making the notion of contamination routine.

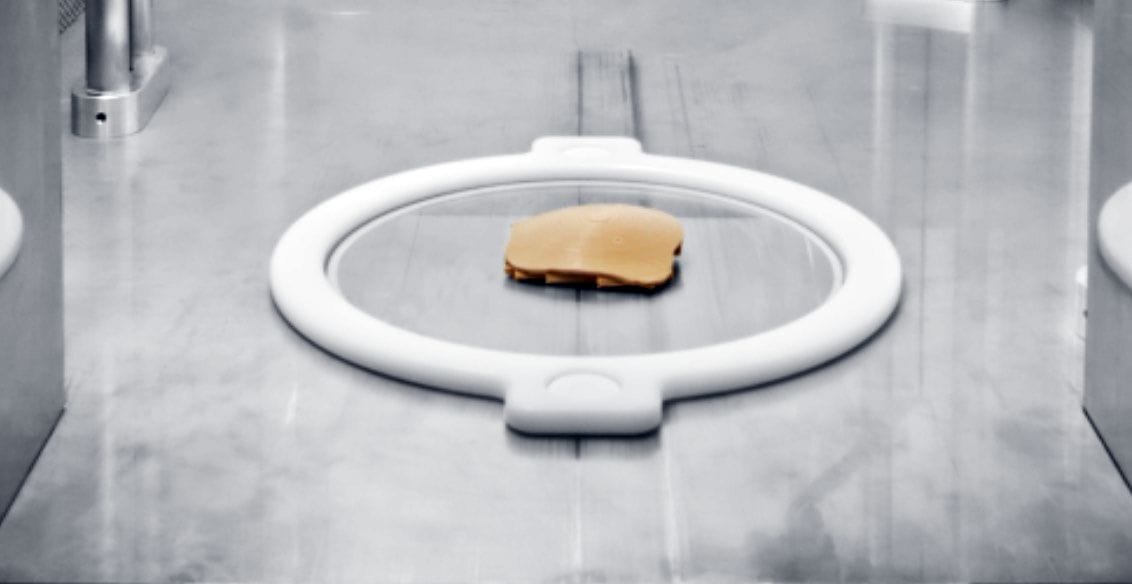

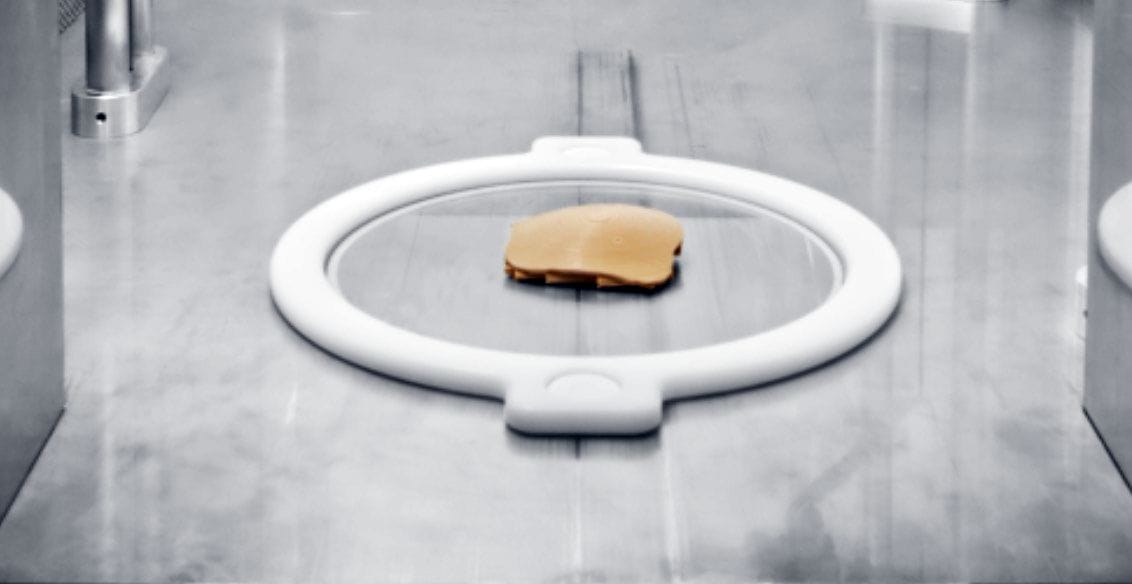

What Kumovis appears to be doing is building a high temperature 3D printer whose build chamber is also considered a “clean room”. I don’t believe this has been attempted previously.

Is it achievable? I think so, as there are plenty of non-3D printer examples of clean room systems. Here it just seems to be a matter of integrating that knowledge and process into existing 3D printer concepts.

Along with the machine and its clean room filtration capability would also be a number of operational processes that would be significantly different from the usual practices of operating a 3D printer. You wouldn’t want to contaminate a freshly printed object just by removing it from the printer, would you? I expect they’re working on pre- and post-printing workflows that would ensure proper handling of material and object.

It’s not clear how far into the product development Kumovis might be at this stage, as they’re not publishing much, aside from the intriguing clean-looking build chamber at top.

But the project appears to me to be entirely feasible, not only technically, but also financially: if they were able to produce such a machine, it could very likely be the only such 3D printer available in the world. That will surely gather customers.

More broadly thinking, I’m wondering if their work heralds more types of highly specialized 3D printers. There are many industries in the world, and they all have peculiarities that must be addressed.

So far most 3D printers are essentially “generic” in that they simply “make stuff”, usually without regard for the purpose and use of the stuff.

If Kumovis succeeds, we may see a sudden wave of specialized 3D printers emerging.

Via Kumovis and Innovation Origins