I recently presented to a sold-out audience at MD&M East, a leading conference in manufacturing medical devices and surgical instruments.

My presentation covered the trends and emerging technology in metal 3D printing. This article summarizes the seven main trends I highlighted in the presentation, which led to a lively and engaged discussion with the audience of 100+ manufacturers and suppliers.

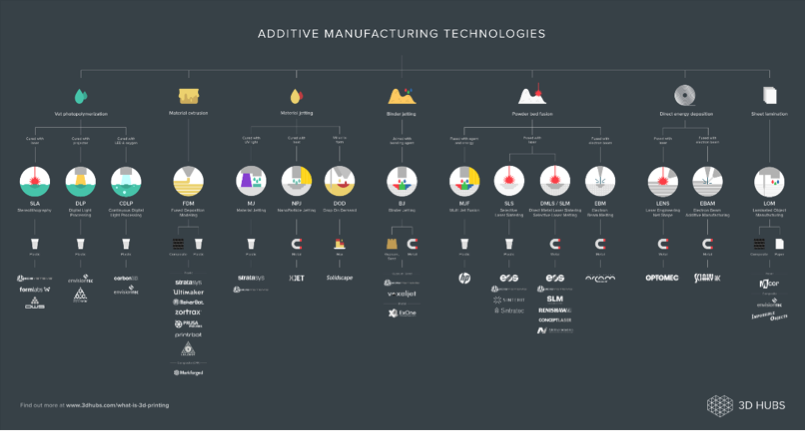

Explosion of Different Types of 3D Printing

The first trend observed is there is currently an explosion of different types of 3D printing, both within metal 3D printing and beyond. There are so many new announcements happening every week that it’s hard to keep up.

Of course, the announcements include metal and plastic 3D printing. But we’ve also recently heard about 3D printing of human organs, food such as dessert and pancakes, and even entire real estate structures. Clearly, 3D printing is an exciting emerging technology that’s being applied broadly in every industry.

Broad Adoption is at an Inflection Point

Believe it or not, 3D printing has been around for nearly four decades. Yet, before the last couple of years the growth was slow and largely disappointing. Then, it suddenly took off.

Clearly, we are looking at an inflection point of market acceptance and adoption in many of the largest industries in the world. For example, PwC wrote a market research report that “Within five years, 85 percent of spare parts suppliers will incorporate 3D printing into their business.”

Companies that invested in the new technology early are starting to reap the benefits, and products with production 3D printed end-use parts are hitting the market in a big way this year.

This is the Year of Metal 3D Printing

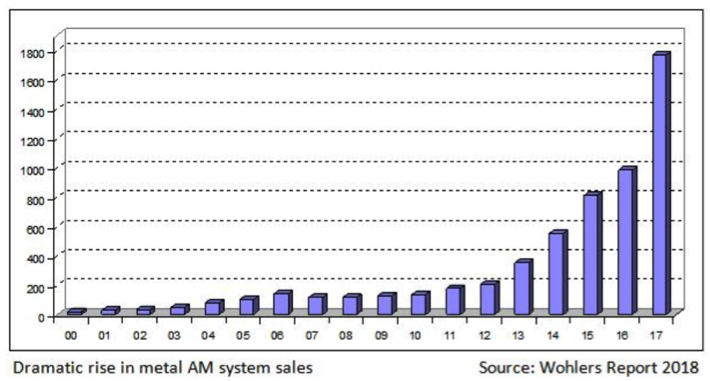

As Terry Wohler’s put it best, this is the year of metal 3D printing. The chart below shows the magnitude of this growth and market adoption happening in metals. The metal 3D printing systems sold in 2017 grew by an eye-popping 80%!

Main Trend: Focus on Production

At RAPID, the leading 3D printing trade show, production grade 3D printing technologies – especially metal 3D printing – were the talk of the show. Every metal 3D printing company is trying to find a way to offer production solutions to its customers.

Some legacy technologies are scaling to production through parallel manufacturing – basically multiplying throughput by adding machines. Need twice the number of parts? Add twice the number of machines! 3D Systems’ Figure 4 links multiple printers on a production line to automate and scale production. Laser sintering companies are following a similar path by adding lasers to their machines. Instead of one laser, four lasers will multiply throughput.

Of course, there are brand new technologies also hitting the market that were designed and optimized for production. Rather than taking a legacy technology and trying to make it go faster, these companies have developed new 3D printing technologies, built specifically for production. 3DEO is a great example of this kind of new technology. The company only accepts small parts to ensure throughput remains high and each printer is capable of printing 1,000 end-use pieces per day. In the current facility, the company will be able to house 50 machines and manufacture up to 50,000 end-use parts per day.

Flood of New Entrants

To the uninitiated, the plethora of metal 3D printing options and technologies can be massively overwhelming. The bad news is it’s going to get much worse before it gets better. The field of metal 3D printing is on the cusp of exploding with new technologies.

In fact, many new metal technologies have already been announced this year, and there are even more on the way. If you’re thinking about investing in a very high cost metal 3D printer today, it might be wise to wait a couple years. The market is moving so fast that any equipment purchased today might be obsolete in only a few years.

But don’t get me wrong – that doesn’t get you off the hook when it comes to investing in 3D printing. Instead of buying capital equipment, you should work with a service bureau that already has the equipment. This allows you to get started immediately at a tiny fraction of the cost.

Dose of Reality

A subtle but noteworthy trend happening in metal 3D printing is that the machine makers and practitioners now have a healthy dose of reality.

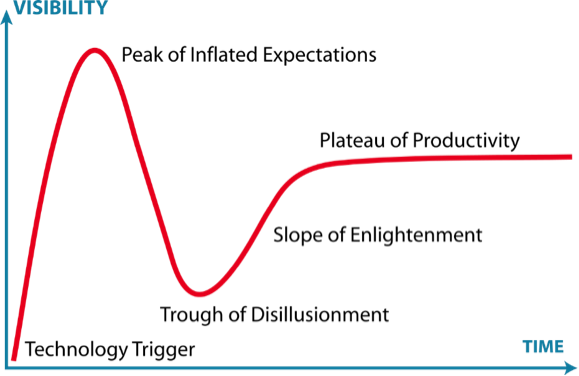

They realize that 3D printing is not the panacea it was promised to be in 2012/2013 when we were at the peak of the Gartner hype cycle (see Peak of Inflated Expectations below). Instead, practitioners are learning how to create winning business cases and how and when metal 3D printing makes sense versus competitive or traditional manufacturing techniques. Metal 3D printing is actually destined to be one tool, albeit powerful, in a manufacturers toolkit alongside conventional manufacturing such as CNC machining, casting, and MIM/PM.

Advances in Software

Software is another key trend happening in metal 3D printing. Until recently, a user’s experience with 3D printing software was underwhelming to say the least. Multiple programs were required to design the part, prep it for printing, complete the build and process it afterwards. Software developers have begun to comprehend the market potential, better understand the vast array of target applications and develop holistic solutions for users.

There are also exciting developments on the design side. Generative design is becoming buzzworthy, and over time this will allow software programs to automatically modify the designs to achieve the optimum part performance at the possible lowest cost. This is a trend that’s just starting and will be interesting to watch over the next decade. #part

Now is the Time to Get Involved with Metal 3D Printing

We are at an inflection point, and now is the time to start implementing 3D printing. If you are not actively engaging 3D printing – even if only on a prototyping scale – you are already falling behind. Significant competitive advantage will be gained by those who adopt metal 3D printing early.

These advantages include faster product development cycles, optimized designs, better products and more agile supply chains which leads, ultimately, to more satisfied customers and profitable revenue growth.

How to Get Started

Capital equipment in 3D printing is often prohibitively expensive. Concept Laser recently announced 10 laser sintering printers for $12 million — $1.2 million per printer. And this cost is just the start as special facilities, processes and knowledge are also required.

So, instead of making massive investments in capital equipment, why not start working with a metal 3D printing service bureau like 3DEO? For 1/1000 of the cost, you could have parts in hand in a week. Perfect your designs, prove your business case, and only then decide whether you want to invest in capital equipment or not.