MakerBot’s materials strategy seems be successful.

The company’s flagship material these days is their “Tough PLA”. It’s a variant of PLA that offers some interesting properties, not the least of which is strength. It also retains the desirable properties of common PLA, which include an ability to print very easily with very little if any warp.

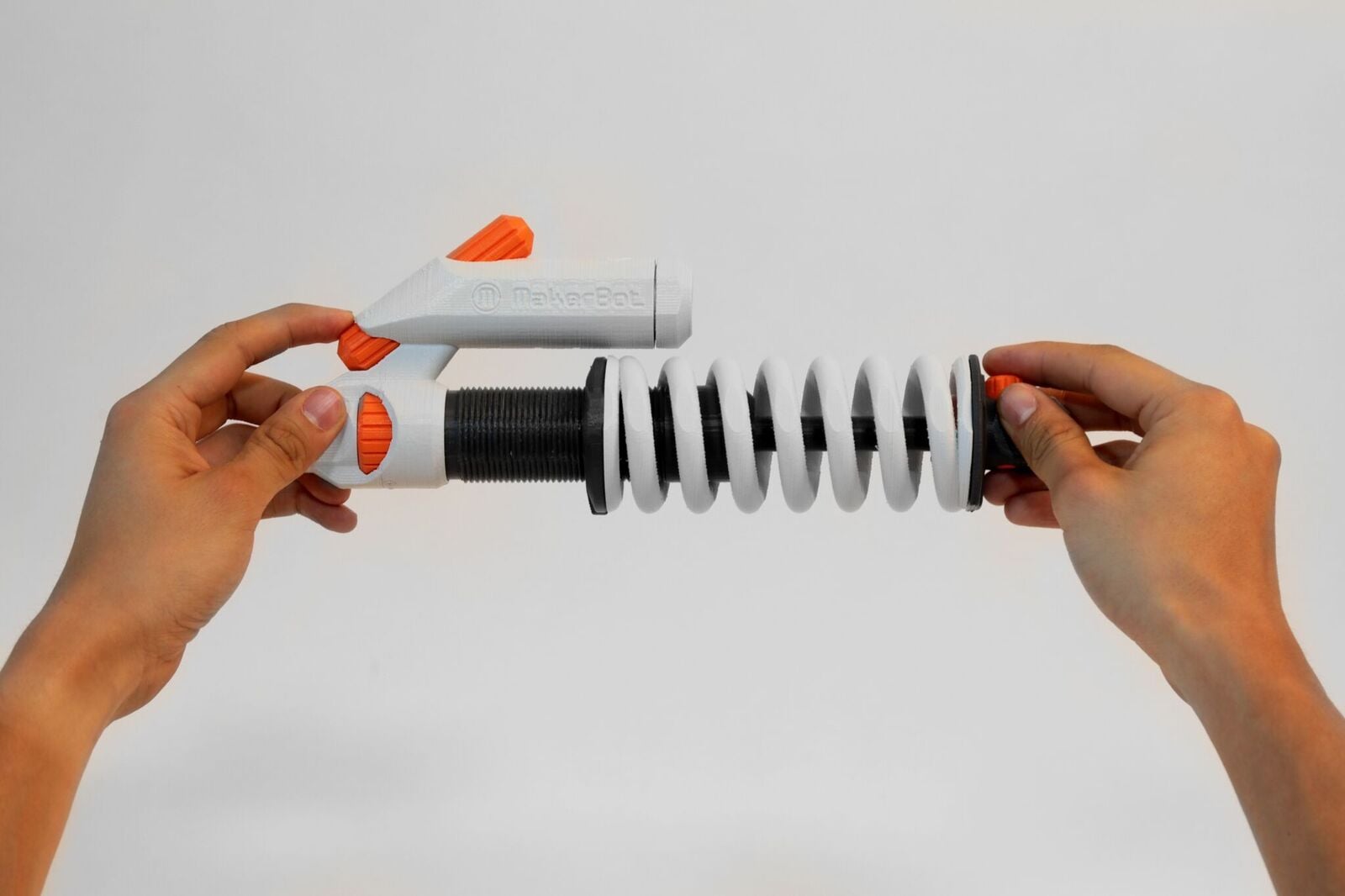

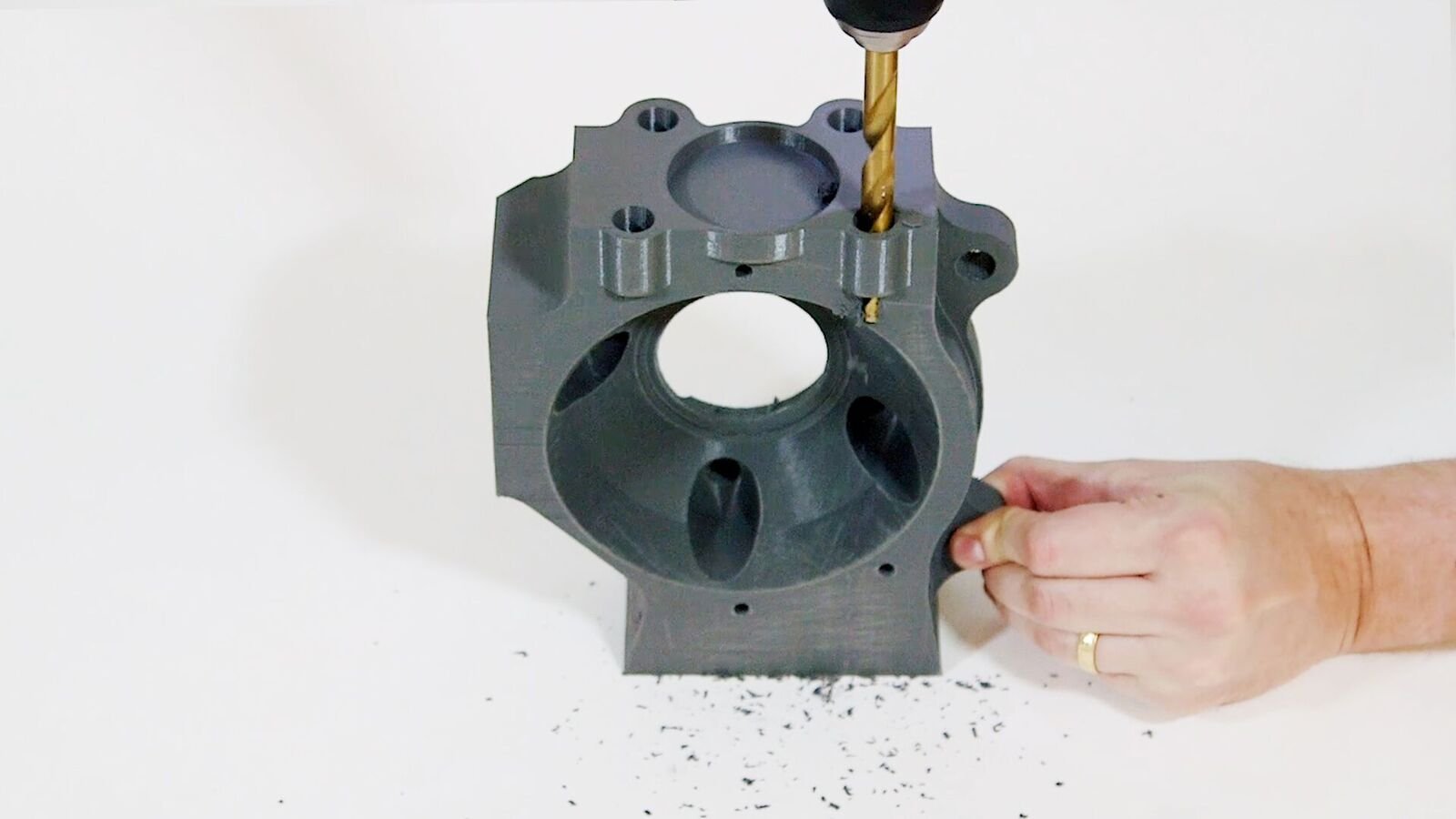

I’ve used this stuff myself and found it extraordinarily useable for making mechanical part prototypes, as it is surprisingly durable. You can bend it, drill into it and more. Check out this video to see what I mean:

That capability combined with their very easy to use cloud-based 3D printing system make a situation where you have a strong ability to “just print a part” whenever you like. It’s hard to describe, but essentially you begin thinking a bit differently about 3D printing when you use their system.

But under the covers here is a materials strategy. MakerBot held the early lead in the desktop 3D printing market, but that seems to have dissipated while the company underwent significant changes and battled tech problems soon after their acquisition by Stratasys in 2013.

During that period their competitors caught up to, and in some cases surpassed MakerBot in terms of technology. Many of them focused on professional markets who eventually drove them to support more exotic materials such as nylon, PETG and more. Some even pursued high temperature materials such as PEEK or PEKK.

But those pursuits require a significant redesign of machines to accommodate the additional temperatures required. Meanwhile, MakerBot’s equipment was largely still at the “cold printing” stage.

And surprisingly, it still is. Their flagship 3D printer, the Replicator+, does NOT have a heated print surface, unlike almost every other serious desktop 3D printer these days.

How is it that they can succeed with a 3D printer that doesn’t include that seemingly basic feature?

It’s because of the materials.

They’ve deduced that their customers don’t really care so much about the technology, but merely need a part that can function in whatever application they’re working on. So instead of complicating the machine by adding a bunch of heat systems, software, procedures and other complications, they changed the material to “Tough PLA”.

And it works. This strategy of focusing on materials and ease of use has caught on with their customers. While you still see many online complain about “evil MakerBot”, few if any of these folks have been using MakerBot’s latest system, and instead are still thinking about how things were several years ago.

In fact, MakerBot has now had a little over a year with the new material, and now they’ve even announced that it’s now available in four colors: the original “Slate Grey”, “Stone White”, “Onyx Black” and in a nod to the possible applications of the system, “Safety Orange”.

All 3D printer companies have made a transition over the past few years to find a new niche for them to market within. With Tough PLA, MakerBot has found theirs.

Via MakerBot