Fabbaloo reader Nick asks about Safe Resins.

Resins are a big part of 3D printing as they are used in several different 3D printing processes. Typically the resins are a special “photopolymer” type that reacts when exposed to certain wavelengths of light. The reaction is solidification, and by using an ingenious motion system, this chemistry can enable the production of solid 3D objects.

But there’s often a problem.

The resins are frequently toxic.

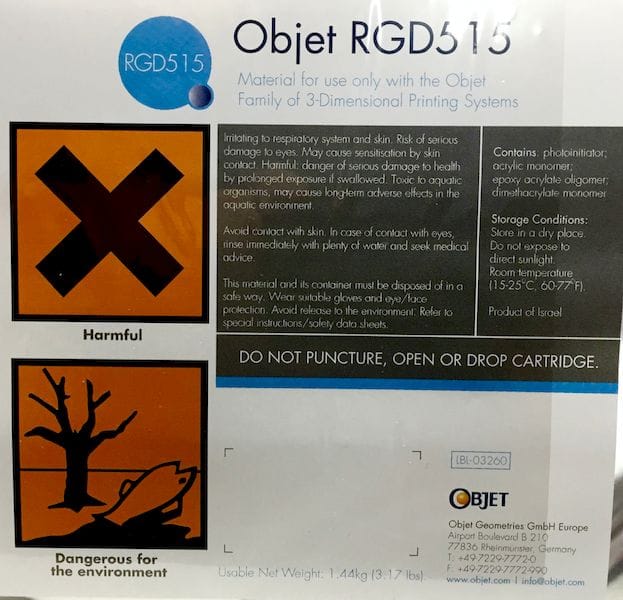

Consider this label from a Stratasys Connex machine for their RGD515 material. It says:

Irritating to respiratory system and skin. Risk of serious damage to eyes. May cause sensitisation by skin contact. Harmful: danger of serious damage to health by prolonged exposure if swallowed. Toxic to aquatic organisms, may cause long-term adverse effects in the aquatic environment.

Avoid contact with skin. In case of contact with eyes, rinse immediately with plenty of water and seek medical advice.

This material and its container must be disposed of in a safe way. Wear suitable gloves and eye/face protection. Avoid release to the environment.

That doesn’t sound very good at all.

But the truth is that many photopolymer resins are much the same with respect to safety. The originating company may not label it as prominently as Stratasys, but a lot the the chemistry would be similar.

I find it thus very surprising that many desktop resin 3D printer operators do not follow these safety procedures. I often see casual operators with resin all over their hands, and that’s just not a good thing.

It’s unfortunate, but the majority of 3D printer resins are like this, and the intent is for them to be used by operators in the proper manner.

But are there “safe” resins? Reader Nick asks:

Can you tell me what resin manufacturers produce safe resins?

I came across 3Dresyns, but can’t find any others that are not hazardous. Some are worse than others, but I’m looking for a cheaper alternative to the 3Dresyns.

3Dresyns, the “innovative maker of speciality resins”, produces a wide variety of resins, including some specifically targeted at popular industries such as jewelry, dental and prototyping.

Their “Specialty” section lists a number of interesting resins, such as fiber reinforced resin, electrically conductive resin and even “two photon” resin that’s used for nano-scale 3D printing where single photon printing is a thing.

But among their specialties is a number of biocompatible resins. These are materials that are specifically designed to 3D print objects for use on or even embedded within the human body. These resins are made differently. 3Dresyns explains:

The basic components of our bio-based 3Dresyns are “green” and are mainly based on natural biological derivatives, which are synthetically functionalized to react with light.

Our 3D resins bio materials exhibit a broad range of physical properties, from super ultra hard and tough SUHT (non brittle) to flexible and elastic grades for the manufacturing of medical devices (Class I, IIa & IIb of ISO13485:2016).

It is certainly possible to find “safe resins”: they are simply the biocompatible materials, which can be found at other sources, even including Stratasys, who produce several biocompatible resins for their machines.

The problem is that these materials tend to cost more. In order to be biocompatible, a company making the product must obtain various certifications from the relevant regulatory authorities. The process of gaining certification is often long and requires considerable expense and effort.

Once obtained, however, a company has, at least a the beginning, a near-monopoly on the material and thus can charge more for it. Even without the perceived monopoly, they should still charge more simply to recover the cost of obtaining the certification.

So we live in a world where you will no doubt pay more for “safe resins”. At least you can buy them, if you need them.

Via 3Dresyns