I’m reading a fascinating report by Joel Simon on his work to “generate” the design of a school.

Manhattan-based Simon, trained in the unlikely combination of computer science, fine arts and bioinformatics, was interested in automatically generating a floor plan to optimize various factors. He explains:

The research goal is to see how a combination of explicit, implicit and emergent methods allow floor plans of high complexity to evolve. The floorplan is ‘grown’ from its genetic encoding using indirect methods such as graph contraction and emergent ones such as growing hallways using an ant-colony inspired algorithm.

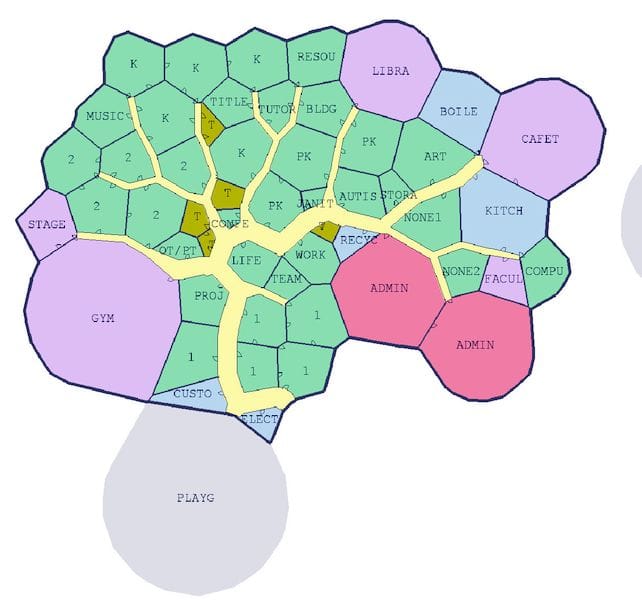

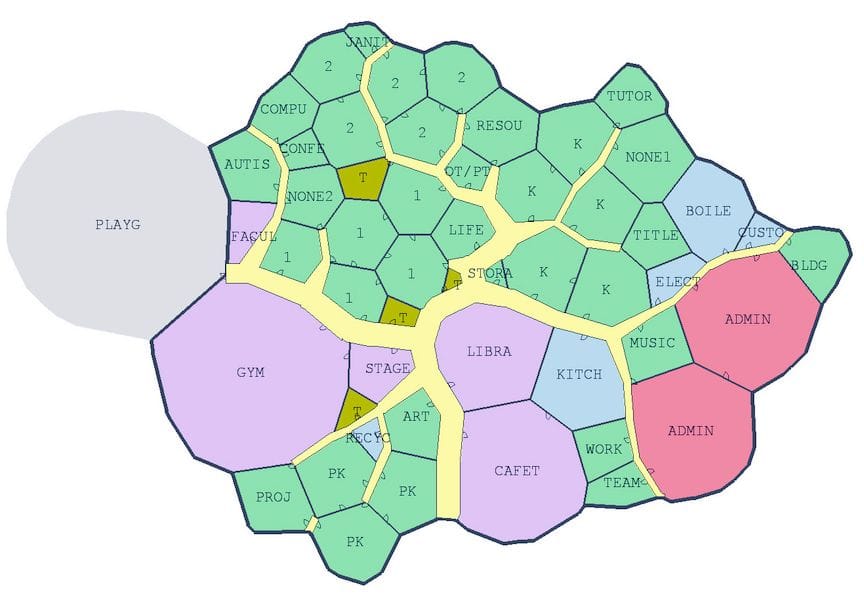

By taking an actual school design, combined with statistics regarding traffic flow between different locations within the school, Simon was able to use advanced genetic algorithms to generate a new floor plan that optimizes for traffic. The result is shown here at top.

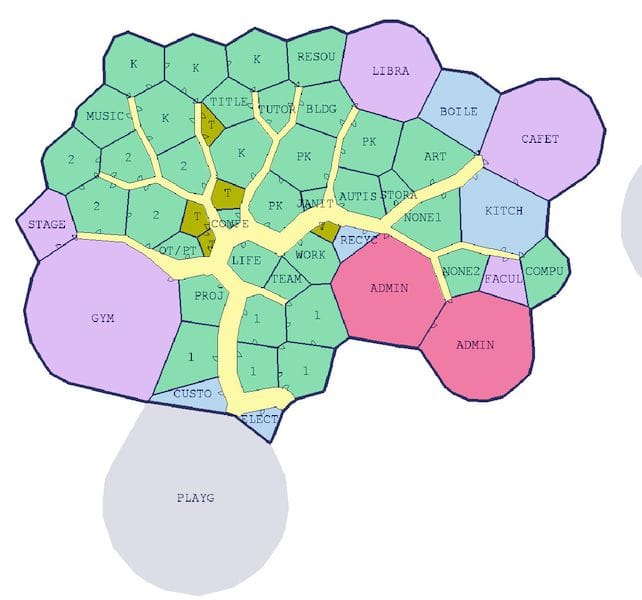

A second result, shown here, is the same school and traffic pattern, but with the added constraint of ensuring easy access to fire exits.

This is a fascinating result that would surely be incredibly impressive visually, as well as functionally, if actually built.

However, Simon also says:

The creative goal is to approach floor plan design solely from the perspective of optimization and without regard for convention, constructability, etc.

And

The results were biological in appearance, intriguing in character and wildly irrational in practice.

And

By not obeying any laws of architecture or design, it also made the results very hard to evaluate. I hope it elicits some ideas in the reader about the future of generativity and design.

So the question is whether this design could actually be built. I have no idea, but I do know that there are rules for engineering, design, architecture and other aspects that could potentially be integrated into Simon’s algorithm.

If so, the results might actually be constructible.

But here’s where 3D printing comes in: the organic designs are complex and likely would cause shudders among actual builders, who are accustomed to building things with straight lines and 90 degree corners. (Well, their managers might be happy as they would be able to quote huge price increases for such a build.)

To keep the costs down it may be possible to build such complex structures using 3D concrete printers – at least the basic wall structures. The remainder of the work, HVAC, plumbing, electrical, windows, surface finishings, etc., would be done in the normal fashion, but would be of more or less the same quantities as a conventional design – and thus cost about the same.

Building highly functional structures such as Simon proposes is where I believe the future lies. If we can use our AI tools (genetic algorithms in this case) and robots (3D printers) to build these things, why wouldn’t we?

Perhaps someday in the far future such structures would be commonplace, and one may look upon today’s standard edifices as somehow outmoded, obsolete and poorly functional.

Via Joel Simon