Researchers at Penn State have developed an unusual way to bioprint cartilage.

Cartilage is material found in animal bodies to provide elastic connectivity, protective coverings for bones and other structural components. One failing of this material is that if damaged it cannot repair itself.

It’s also one of the materials researchers would like to 3D print into new structures that can replace those that have been damaged. However, there’s a problem.

Typical bio printing approaches involve squirting bio material (usually cells of some type) into a gel where they gradually grow together. However, this doesn’t work with cartilage. Penn State researcher Ibrahim T. Ozbolat explains:

Hydrogels don’t allow cells to grow as normal. The hydrogel confines the cells and doesn’t allow them to communicate as they do in native tissues.

Ozbolat’s team developed an entirely new process, which we’ve not heard of previously. Their approach involves inserting a number of cartilage cells into an very thin alginate tube. Over a period of a week, the cells link together naturally, and then they can be easily removed as cartilage does not stick to alginate. This produces a “cartilage filament”.

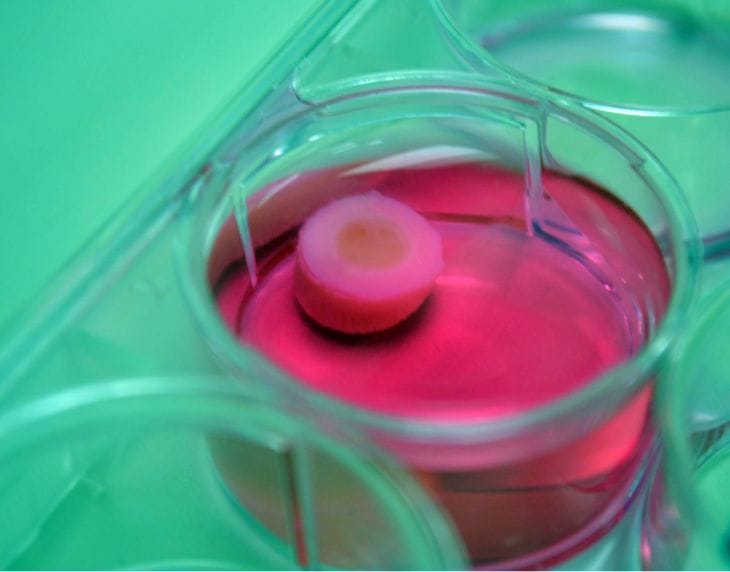

The next step is to use this new filament in a more or less standard 3D printing setup to extrude strong strands of cartilage to the desired points in a larger structure. The print, placed in an appropriate nutrient solution gradually binds together to form a final cartilage object, theoretically suitable for medical use.

The best part of this process is that the strands can be made of any length, thus enabling the creation of many types cartilage prints.

I’m wondering if this technique – that of “cooking” materials in a tube before finalizing a filament – is suitable for other materials, or even non-biological materials. This concept could open up some interesting possibilities.

And then there’s this:

Via Penn State