We hadn’t heard much from NewPro3D until an interesting chat recently.

We first encountered the Vancouver-based 3D printer startup company at CES in early 2016, where they were showing off an incredibly fast resin-based 3D printer. At the time, Carbon was also starting up with a similarly fast 3D printer, but since then they’ve secured far more funding than NewPro3D and have grown significantly. Meanwhile, NewPro3D’s technology is still valid and they’re preparing to launch their product later this year.

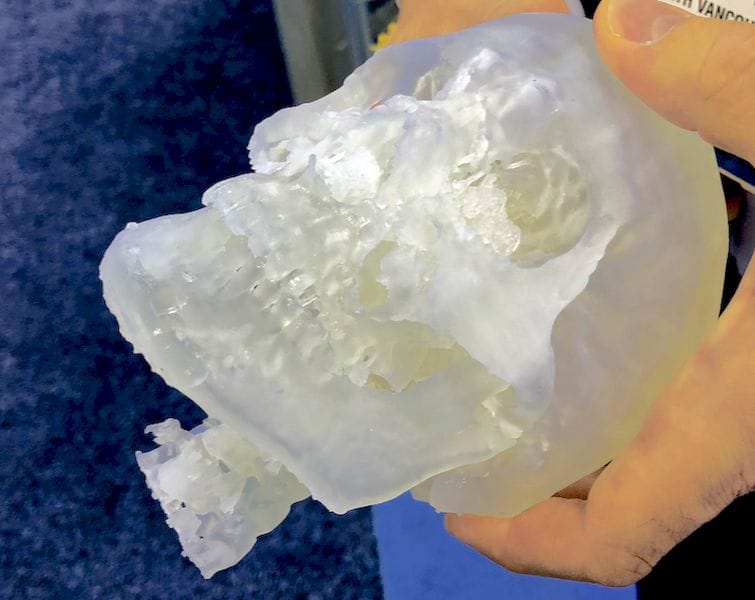

A typical 3D print on the NewPro3D equipment, such as this skull, can be accomplished quite rapidly. We’re told prints of this size can easily be completed in only 75 minutes! That’s very fast for any 3D printer.

What’s the secret to their speed? It has to do with what they call their “ILI” technology, which is a proprietary method of avoid the “stick and peel” problem suffered by most resin-based 3D printers.

The problem occurs when the fusing laser shines through the transparent bottom of the resin tank to solidify a layer. While the liquid photopolymer is fused together, it also fuses the bottom of the tank!

In order to proceed to the next layer, most resin 3D printers employ a “peel” process in which they very slowly tip the build plate (or tank) to carefully peel the layer off the bottom, hopefully without damaging either the print or the tank bottom.

This peel process works, but gradually erodes the tank, which eventually must be replaced. In addition, the duration of the peel adds significant time to the build: each and every layer must suffer a peel delay.

So the game here is to somehow stop the solidified resin from sticking to the tank bottom. If you can do that, then you can effectively print continuously: just keep raising the build plate and firing the laser, so long as the flow of liquid resin can quickly slosh into the empty spaces between the print and the tank bottom.

Carbon solves the problem with a tank bottom that’s impregnated with oxygen, which chemically suppresses solidification near the tank bottom.

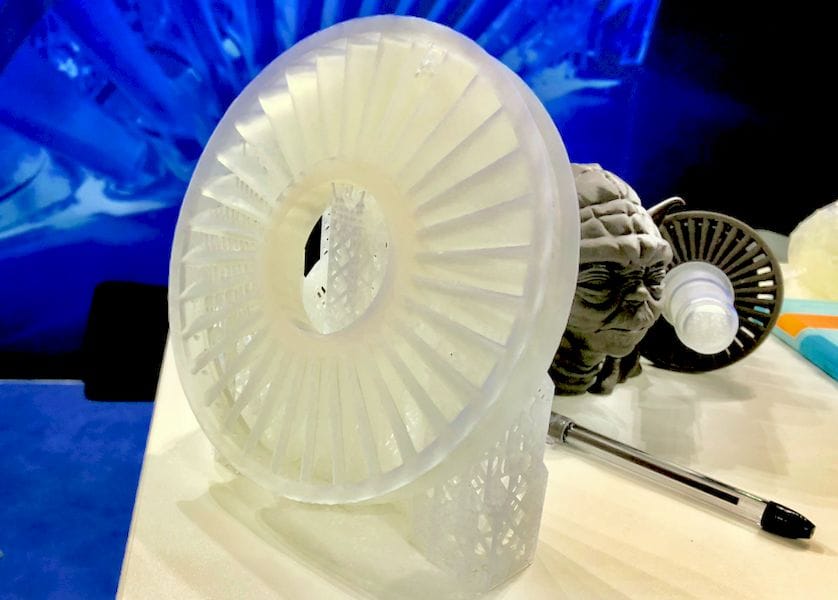

NewPro3D solves the problem differently. Their ISI system involves a “wettable membrane” that prevents sticking. They explain:

The Intelligent Liquid Interface is a transparent wettable membrane between the photo-curing resin and the light source. The membrane is chemically designed to enable faster movement between cured layers. This eliminates the mechanical processes used on conventional 3D printing techniques allowing us to grow objects at record breaking speeds.

The membrane is not permanent; it’s considered a consumable. NewPro3D explained to us that if one were printing continuously it would last 2-3 days, or up to a week if printing intermittently.

But a mere consumable is not an issue if you can print so quickly. A 3D print service bureau, for example, could print more for customers during the period, and the profit from those extra prints could easily pay for the consumable.

There’s another advantage to a non-stick tank: more delicate structures are possible. Imagine a very delicate structure being 3D printed, and on each layer it would have to undergo the stress of being peeled off the tank. Some geometries would not be strong enough to deal with this, and could break. That scenario does not happen with NewPro3D’s system.

NewPro3D told us they’ve been experimenting with different light sources for quite a while, but are now very happy with the result. The machine is being readied for production, with first deliveries slated for Q4 of this year. They expect a price of about USD$90,000 per unit.

Unlike some other expensive resin devices, the NewPro3D machine will be able to handle third party resins, making operational costs potentially lower.

Finally, NewPro3D says it’s possible to make the membrane bigger, so it’s quite conceivable we may see much larger resin machines from the company in the future.

Via NewPro3D