Ultimaker has released the latest version of Cura, their slicing engine.

The Netherlands-based company does the 3D print community an enormous service by keeping the open source Cura engine up to date and filled with great features. It’s used not only by Ultimaker operators to keep their machines running at optimum levels, but also by countless others running other machines with a configuration installed in the freely available open source Cura software.

Cura has undergone many evolutions over the years and its gradually evolved into a very powerful system for managing and operating many 3D printers. It’s sophisticated interface has advanced far beyond virtually all of the alternative open source 3D print slicing options.

The new version, which arrived last week, includes a number of interesting new features. While they’ve included support for a few newly released 3D printers and fixed a batch of bugs, here’s the ones we felt were of most interest:

They’ve added a cloud feature that can be used to backup settings, which include printer definitions, materials, and printing parameters. This will be particularly useful when migrating software between computers, or potentially sharing with distant others.

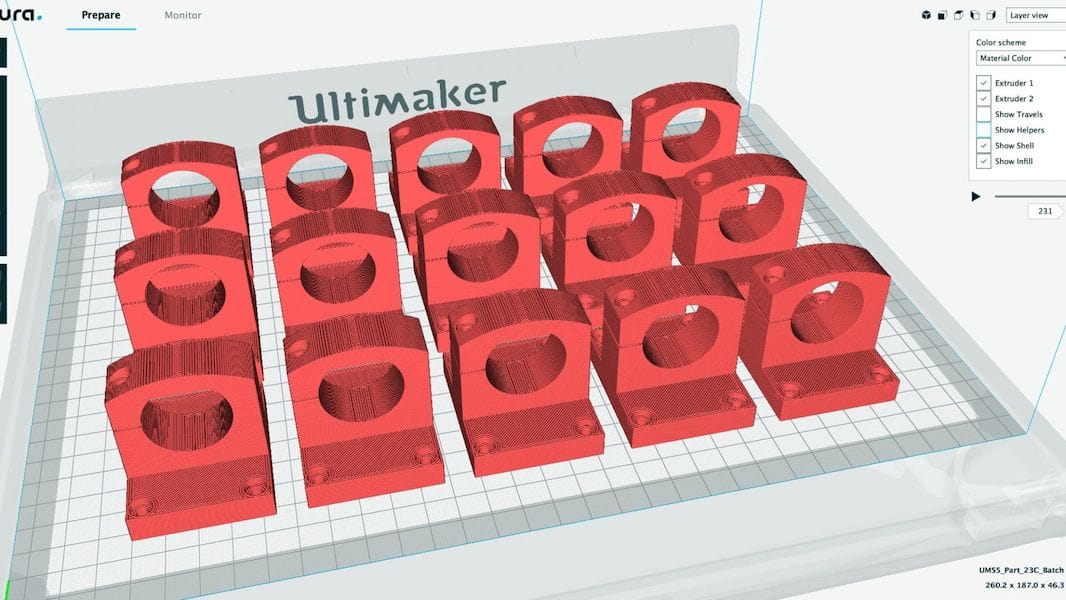

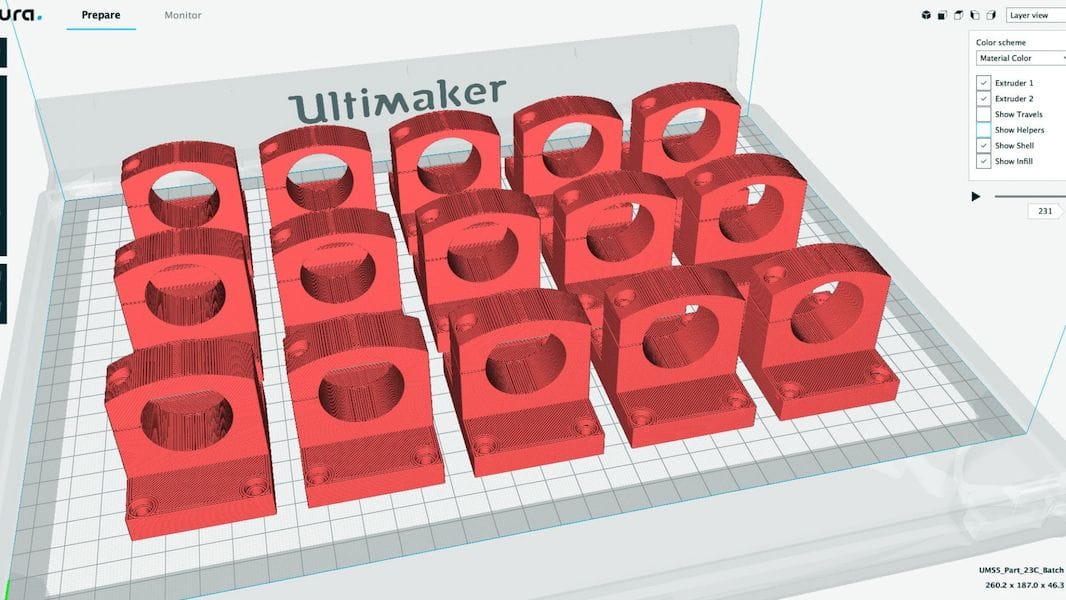

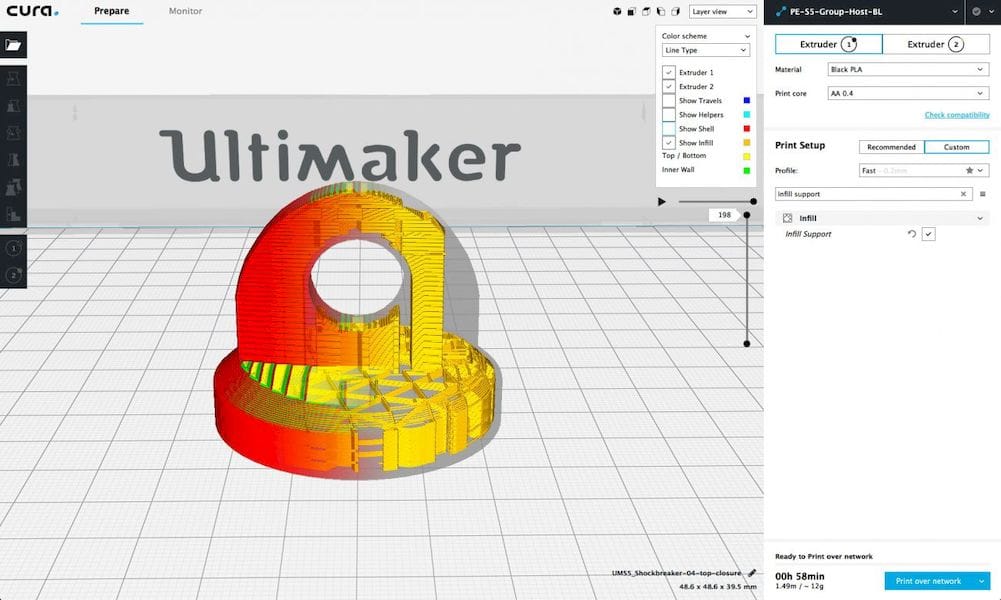

An infill optimization feature is added, in which infill is generated intelligently. I’m sure you’ve seen large swaths of generic, uniform infill waste significant amounts of material. But you have to do that even if you need the denser infill only in a certain area. Not anymore! The new infill support feature generates infill only when required, thus reducing not only material use, but also speeding up the print time.

There’s now a ton of options for fine tuning retraction operations. Retraction is a critical feature for many complex 3D prints, and now you can fiddle with settings until you get it right.

One of my favorites in this release is the “print perimeter before holes” feature. This is trying to overcome the persistent problem of printing small holes on the first layer. Typically slicers end up printing the outlines of these first, leaving tiny donuts unprotected on the print surface. Unfortunately their surface area is small and they are prone to coming loose, especially if bumped by any debris being dragged around by the nozzle.

The new feature basically prints the rest of the layer before hitting the holes, making the donuts simply merge into a large, well-stuck first layer. This should alleviate many print failures.

Finally, they’ve added some plugins to accommodate the integration with several third party 3D modeling tools, including Blender, OpenSCAD, FreeCAD and most notably, Autodesk Inventor.

That last one is interesting, as it furthers Ultimaker’s current strategy of working closer with industry. This means those using the Autodesk 3D modeling tool can immediately and directly send files into Cura, bypassing the need for STL conversion – and problems, too, for that matter.

I suspect they may be working on other similar business product integrations that would ease the sale of their equipment into larger manufacturing organizations.

But meanwhile, please enjoy the latest and best yet version of Ultimaker Cura.

Via Ultimaker