I’m always fascinated with unusual 3D printing processes, and Fabrisonic certainly qualifies.

Ohio-based Fabrisonic uses an unusual sound-based method for creating solid 3D objects. Their ultrasonic additive manufacturing (UAM) process is able to create metal objects without melting the materials.

How is this done? Fabrisonic explains:

Ultrasonic metal welding has been around since the 1950’s with modern applications in everyday welding of battery tabs, thin foil packaging, and even electronic wires.

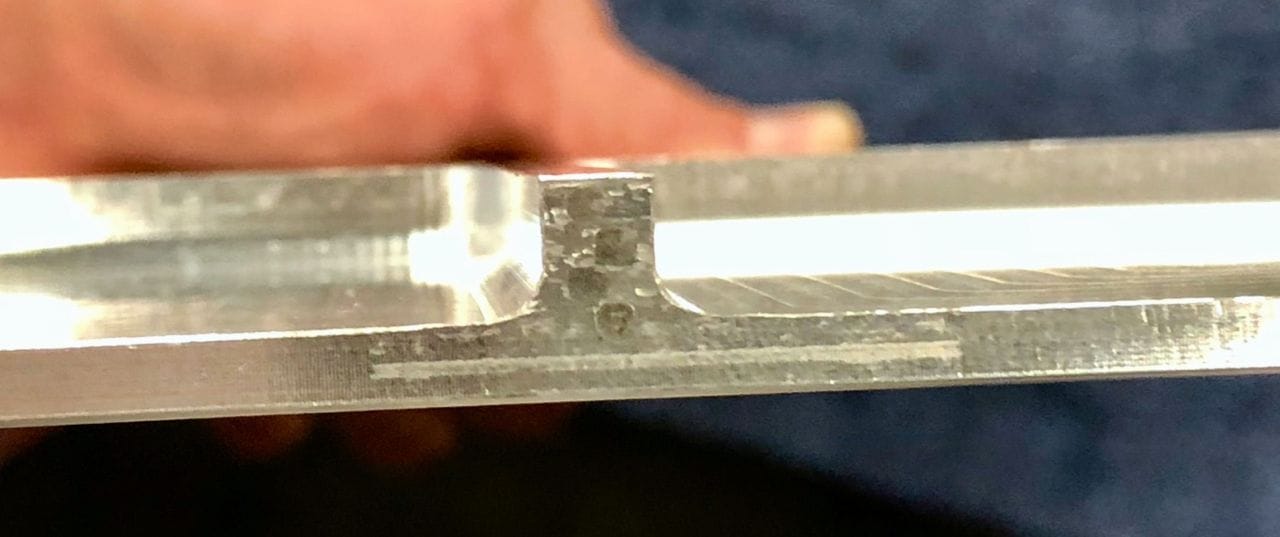

An ultrasonic weld operation begins by pressing a thin metal foil onto another metal component. While under a constant force, ultrasonic vibrations are applied to cause scrubbing of the mating faces. This shearing motion cleans off surface oxides through friction to then allow direct contact of pure metal on pure metal.

The result is in a solid state atomic bond with minimal heating. The heat and plastic deformation promote diffusion and recrystallization at the interface resulting in a true metallurgical bond. Ultrasonic welding can be accomplished at very low temperature and without any special environments.

For all metals, the bonding temperature is significantly below their respective melting temperature. In aluminums for example, this peak temperature is always below 250 °F.

This surface welding technique allows the possibility of creating objects with unlike metals that would not normally be able to be built together. Here we see an object with a mix of ceramic and metal.

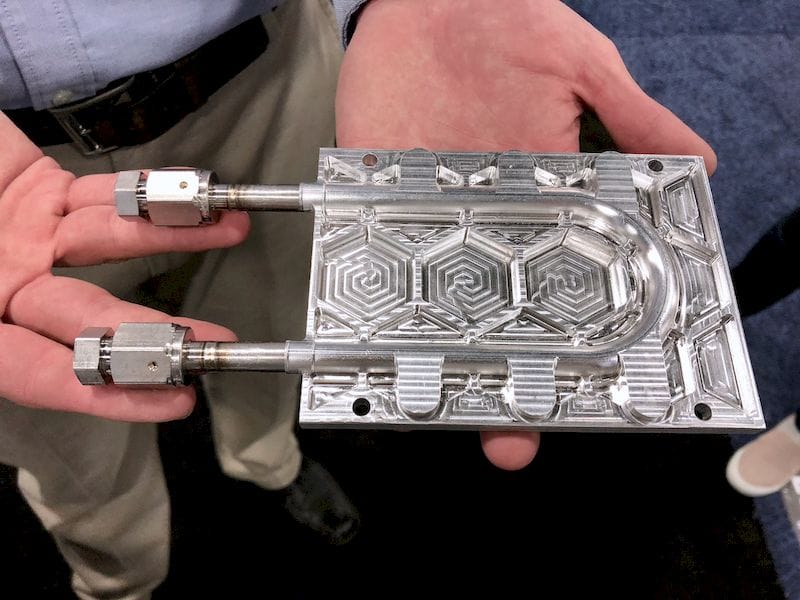

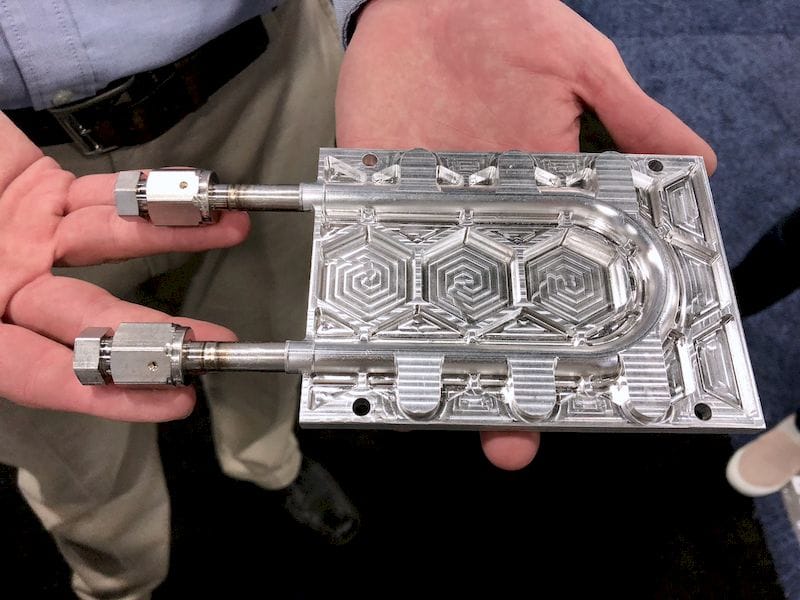

Fabrisonic combines this bonding approach with a traditional CNC milling toolhead to both deposit and surface finish the parts to perfection, as you can see in the example images here.

As you can see, this process is vastly different than typical metal 3D printing processes that involve supreme heating with laser or electron beams, and also different than the up and coming “cold” processes that print “cold”, but still require sintering in furnaces after printing.

But as the process is different, the applications may also be different. For a company introducing a new technology the challenge they face is that potential clients may not understand how they can apply the technology. It then becomes an educational problem where the new technology manufacturer has to teach their clients how best to use the tech.

Fabrisonic seems to be making strides forward in this aspect, as we recently saw several examples of test parts that were built for the aerospace industry.

Fabrisonic’s process produces parts with greater molecular bonding than some other processes, making the resulting parts a lot stronger. That’s critically important in aerospace and certain other industries, as the parts can be smaller or thinner and still perform their required function.

And of course they also can produce the same advantages of other 3D printed objects, such as fewer components, lower weights, less waste material, faster turnaround for unique objects and more.

But they will succeed only if industry adopts their technology, and that requires exposure and education. As we’ve seen with other 3D metal printing processes, it took years for industry to come around and realize the advantages they could take on by using the technology. It may be some time before Fabrisonic can achieve the same results, but they’re working on it.

Via Fabrisonic