This week’s selection is the finely detailed Voronoi Flower Lampshade by designer Felicity Anne Holbrow.

Oakland, California based Holbrow has produced a number of fascinating 3D designs as shown on her website. Many of her designs focus on medical applications, such as a prosthetic hand she’s designing.

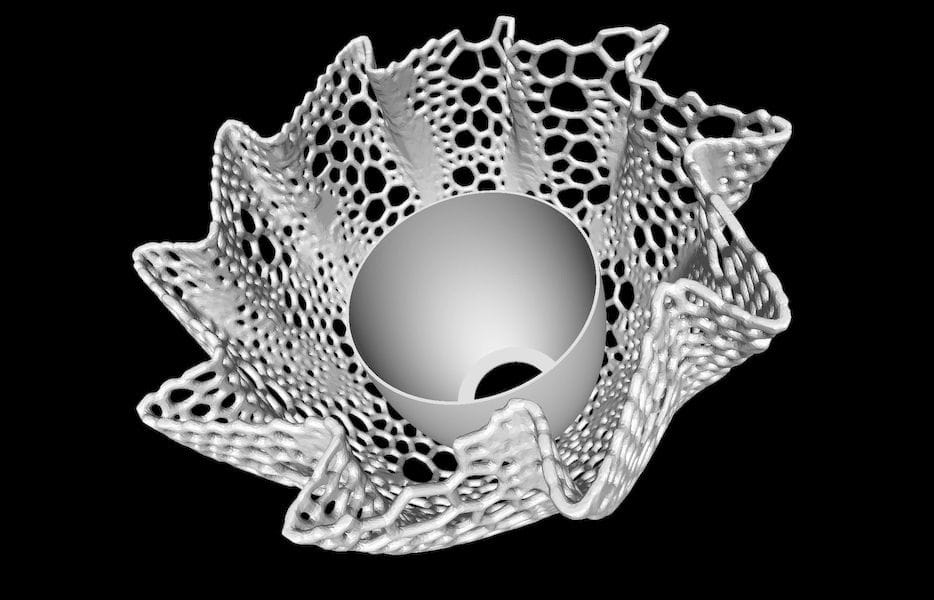

But this week we’re attracted to her beautiful Voronoi Flower Lampshade, which, as you might imagine, can be attached to a lamp to replace the commonly found plain lampshades.

The “Voronoi” in the item’s title refers to a 3D modeling technique in which an otherwise solid 3D model is “holed” in random ways to create a sparse shape that follows the contours of the original design.

One interesting feature is an inner shield that surrounds the light source – which, by the way, should almost certainly be a cold LED light, as hot incandescent sources may compromise the possibly low temperature thermoplastics used to 3D print the lampshade.

The shield prevents the lampshade from generating a shadow pattern that could be extremely interesting for a short while, but distracting in the long term.

I particularly like the wavy nature of the pattern, which at some visual angles appears to be draped over the lamp like lace.

This design is best suited for use on certain IKEA lamps. Holbrow explains:

Fits on some generic IKEA/Target type lamps but can also fit with cords like these ones sold on Amazon.

Astute 3D printer operators will immediately notice the incredible detail on this particular 3D model, and may shudder at the prospect of attempting to 3D print this item on basic desktop 3D printers. Again, Holbrow explains:

This was designed with the intention of being printed on EOS formiga SLS printers, but if you have a solid FDM printer, it might be up to the challenge. If you do want to print it with FDM, I definitely recommend adding a z-hop into your slicer settings and cutting off the bottom 0.2mm or so since it is not completely flat.

It’s likely possible to attempt to 3D print this lampshade, but you’d better have a very carefully tuned 3D printer able to withstand the repeated retractions required on each print layer.

Or perhaps you have access to a more powerful 3D printer that is able to handle the geometric complexity, such as a large-format resin 3D printer or powder based equipment as Holbrow recommends. You can also 3D print this with almost any 3D print service, who typically have this type of equipment.

You can download this model from Ultimaker’s YouMagine 3D model repository.

Via YouMagine and Felicity Anne Design