A new development might lower the cost of 3D print material that uses carbon nanotubes.

Let’s get one thing straight right away: 3D printers cannot 3D print carbon nanotubes per se. Carbon nanotubes are microscopic carbon atoms that are linked together in the form of a tube. Think of a quilt that’s composed of carbon atoms, and then rolled up into a tube.

These tubes can be macroscopically long, even though their structure is microscopic. Thus the physical forces holding together the molecule are apparent at normal object sizes. It’s hard to pull apart a single molecule – and that’s essentially what you’re trying to do with a meter long length of carbon nanotube, if you could get one that long.

Thus carbon nanotubes are ridiculously strong, and accordingly highly desired for engineering projects.

To date, however, the production processes for carbon nanotubes are inefficient and unable to make anything other than relatively short-length tubes. Even worse, the cost of doing so means you’ll be paying up to USD$200 per kg of these short-length carbon nanotubes.

How are carbon nanotubes used in 3D printing? They are sometimes added to a standard thermoplastic polymer, which acts as a binder to form a usable filament. You can purchase “carbon nanotube” filament, which is actually a standard filament infused with large quantities of chopped up / short length carbon nanotubes.

Objects 3D printed with such material are indeed far stronger than you’d expect from just a polymer, but they are far less strong than an object made from continuous strands of carbon nanotubes.

You would expect the cost of carbon nanotube filament to be expensive, and you’d be right. If a kg of filament contained 50% carbon nanotubes, the cost of those nanotubes would be around USD$100 alone. The high cost of carbon nanotubes may be steering 3D printer operators away from use of carbon nanotube filaments.

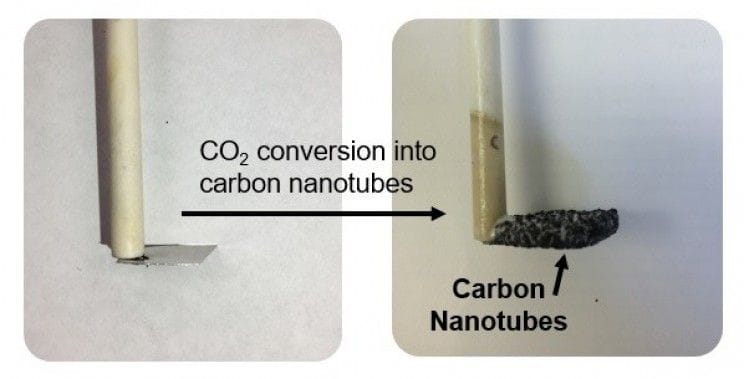

But now we’re hearing that a new electrochemical process has been developed by researchers at Vanderbilt University and SkyNano LLC that could dramatically lower the cost of carbon nanotube production.

Their process involves adjacently placed sheets of iron and aluminum in a salt solution. When current is applied, this arrangement apparently draws out CO2 molecules from the air and begins to form reasonably well defined carbon nanotubes.

It’s not clear how much less expensive the process might be, but from the description of the process it surely could be implemented at a reasonable cost.

And if that comes to pass, then those producing carbon nanotube filament might be able to correspondingly lower their product pricing. Even better, it may entice other filament manufacturers to design and introduce carbon nanotube filament.

Via Interesting Engineering and ACS